When you’re selecting packaging materials for your business, understanding the fundamentals can save you money and improve product protection. If you’ve ever wondered why most corrugated boxes use kraft paper as their outer liner, you’re not alone—this choice affects everything from printing quality to shipping durability.

Kraft paper dominates corrugated board manufacturing because it represents approximately 95% of all corrugated packaging in North America, offering the perfect combination of exceptional strength, superior printability, and proven cost-effectiveness. Made from 80% or more virgin softwood fibers, kraft paper provides unmatched burst strength and tear resistance that alternative materials simply cannot match.

Let’s explore the technical reasons and practical benefits that make kraft paper the undisputed industry standard for packaging professionals worldwide.

Table of Contents

ToggleWhat Makes Kraft Paper Different from Other Liner Options?

Understanding kraft paper starts with knowing what sets it apart in the competitive world of packaging materials. The fundamental difference lies in the kraft process itself, developed in Germany in the 1880s.

The kraft process removes lignin from wood fibers while preserving long cellulose fibers, creating paper that derives its name from the German word “kraft,” meaning strength. This chemical treatment results in superior material properties that no alternative can comprehensively match.

The manufacturing process creates longer, stronger fiber bonds compared to recycled papers. Virgin wood pulp maintains its natural lignin content, which acts as a binding agent between fibers, delivering exceptional performance characteristics.

Virgin kraft liner contains 80% or more virgin fibers from softwood trees, providing high burst strength and superior tear resistance. The long fibers found in softwood trees are tightly woven together during manufacturing.

Testing data demonstrates kraft paper’s clear superiority. Virgin kraft liner typically achieves burst factors of 32+ BF, while recycled alternatives struggle to reach these levels consistently.

| Paper Type | Virgin Fiber Content | Burst Strength | ECT Performance | Typical Cost per Ton |

|---|---|---|---|---|

| Virgin Kraft | 80%+ | 32+ BF | Superior | $300-700 |

| Test Liner | Mixed recycled | 20-25 BF | Good | $300-600 |

| White Top Kraft | Virgin base + bleached top | 30+ BF | Excellent | $400-800 |

| Recycled Liner | 100% recycled | 15-20 BF | Fair | $250-500 |

This superior fiber composition explains why kraft paper consistently outperforms alternatives in demanding applications like heavy-duty shipping boxes and premium retail packaging.

Why Do Corrugated Board Manufacturers Prefer Kraft Paper?

From a manufacturing perspective, kraft paper offers numerous advantages that make production more efficient and reliable. These benefits directly impact your packaging quality and business success.

Manufacturers favor kraft paper because its consistent fiber structure and controlled moisture content ensure reliable bonding during high-speed corrugating operations, reducing web breaks, minimizing waste, and maintaining consistent quality output that reduces production costs.

The corrugator combines liner papers with fluted medium using starch-based adhesive under heat and pressure. Kraft paper’s engineered porosity allows optimal adhesive penetration while maintaining structural integrity.

Manufacturing advantages include:

- Reliable bonding: Engineered porosity ensures uniform adhesive penetration during single-face bonding

- Consistent quality: Controlled fiber structure prevents production variations and defects

- Reduced downtime: Superior wet strength properties minimize web breaks during high-speed production

- Lower waste rates: Predictable performance characteristics reduce material waste and rework

The economic impact extends beyond the factory floor. Manufacturing efficiency benefits include reduced waste, fewer production interruptions, and consistent quality output. These factors contribute significantly to overall cost-effectiveness despite kraft paper’s higher raw material cost.

Chemical recovery systems in kraft paper manufacturing recycle nearly all production chemicals, making the process self-sustaining and reducing manufacturing costs. The main byproducts—turpentine and tall oil—have commercial value, further improving economics.

How Does Kraft Paper Enhance Printing and Branding Quality?

Your packaging serves as a mobile advertisement for your brand, making print quality crucial for business success. The choice of liner paper directly impacts how your graphics, text, and branding elements appear to customers.

Kraft paper’s porous, textured surface provides excellent ink absorption and adhesion properties, enabling high-quality printing results that are increasingly important in competitive markets. The growing kraft paper printing market is projected to reach $27.75 billion by 2031, reflecting increasing demand for branded packaging solutions.

White-top kraft liner variants combine kraft’s strength with a bleached surface layer optimized for printing. This construction allows vibrant, high-contrast graphics while maintaining the structural benefits of kraft backing.

Print quality benefits include:

The smooth, bright white top surface is ideal for high-quality printing applications, making it popular for premium packaging and retail applications. Color accuracy improves dramatically due to uniform surface texture.

Fine detail reproduction becomes possible through kraft paper’s smooth texture that captures small text and intricate designs without bleeding or distortion.

Ink adhesion properties excel because virgin fibers bond effectively with various ink types, from traditional flexographic to modern digital printing systems.

| Printing Method | Kraft Paper Performance | Alternative Performance | Best Applications |

|---|---|---|---|

| Flexographic | Excellent | Good | High-volume production |

| Digital | Superior | Fair | Short runs, variable data |

| Offset | Outstanding | Poor | Premium graphics |

| Screen | Good | Fair | Specialty applications |

Custom printed kraft paper enables companies to extend their brand experience from online presence to physical packaging, creating memorable unboxing experiences that drive customer loyalty. Kraft paper’s natural brown aesthetic communicates sustainability and authenticity, aligning with consumer preferences for environmentally conscious packaging.

What Strength Advantages Does Kraft Paper Provide?

Packaging strength determines whether your products arrive intact, making this a critical factor for any business shipping goods. Understanding how kraft paper contributes to overall package integrity helps you make informed decisions.

Kraft paper delivers exceptional strength characteristics including superior edge crush strength, burst strength, and puncture resistance that translate directly into reduced product damage, lower insurance claims, and improved customer satisfaction compared to recycled alternatives.

The strength characteristics come from kraft paper’s long fiber structure and minimal processing damage. Virgin fibers maintain their natural strength properties throughout manufacturing, creating measurable performance advantages.

Edge Crush Test (ECT) values for kraft-based corrugated board routinely exceed those of recycled liner alternatives by significant margins. This measurement indicates how much force the corrugated board can withstand when compressed from the edge.

Burst strength testing shows kraft paper’s resistance to sudden pressure from inside the box. Higher burst strength prevents package failure during rough handling and impacts.

Puncture resistance protects against sharp objects during shipping. Kraft paper’s dense fiber network resists penetration better than alternatives, maintaining package integrity.

The long fibers found in softwood trees are tightly woven together during manufacturing, creating a robust and durable product capable of withstanding rough handling and heavy loads. This strength translates directly to superior performance in corrugated applications.

How Cost-Effective is Kraft Paper for Large-Scale Operations?

Budget considerations influence every packaging decision, but understanding the total cost picture requires looking beyond initial material prices. The global corrugated packaging market, valued at approximately $208-217 billion in 2024, relies heavily on kraft paper’s cost-performance balance.

While kraft paper costs $300-700 per ton compared to $300-600 per ton for testliner, its superior performance characteristics deliver excellent value in large-scale operations through reduced waste, improved efficiency, and minimized product damage that offset higher material costs.

Several factors contribute to kraft paper’s economic advantages beyond raw material pricing. The kraft process can utilize various wood types, including resinous pine and bamboo, that other papermaking processes cannot handle effectively.

Total cost analysis reveals multiple value drivers:

Raw material efficiency allows access to abundant, lower-cost fiber sources that other papermaking processes cannot effectively utilize. This flexibility provides supply chain stability.

Chemical recovery systems recycle nearly all production chemicals, making the process self-sustaining and reducing manufacturing costs. The main byproducts have commercial value, further improving economics.

Lightweight performance characteristics mean kraft paper’s high strength-to-weight ratio reduces shipping costs while maintaining protection capabilities. This becomes increasingly important as transportation costs rise.

| Cost Factor | Kraft Paper Impact | Annual Savings Potential |

|---|---|---|

| Material waste reduction | 15-25% less waste | $50,000-200,000 |

| Shipping efficiency | 10-20% weight savings | $25,000-100,000 |

| Damage claims | 30-50% reduction | $75,000-300,000 |

| Production efficiency | 20-30% less downtime | $100,000-500,000 |

For businesses shipping high-value products or requiring premium presentation, kraft paper’s benefits typically exceed the additional material costs through improved performance and reduced total cost of ownership.

What Environmental Considerations Apply to Kraft Paper?

Sustainability concerns increasingly influence packaging choices as businesses respond to consumer demands and regulatory requirements. Understanding kraft paper’s environmental impact helps inform responsible packaging decisions.

Kraft paper offers excellent environmental credentials with 100% biodegradability and recyclability, plus wood pulp sourced from responsibly managed forests with FSC certification. Life cycle analyses show the European kraft paper industry reduced its carbon footprint by 17% between 2007 and 2012, achieving emissions of 471 kg CO₂ equivalent per ton.

The environmental advantages create compelling sustainability benefits compared to alternative materials. Wood pulp for kraft paper typically comes from responsibly managed forests that ensure sustainable harvesting practices promoting forest regeneration.

Key sustainability factors include:

- Renewable sourcing: FSC-certified forests ensure sustainable harvesting practices

- Chemical efficiency: The kraft process uses fewer harmful chemicals and produces no chlorine-containing byproducts

- Energy optimization: Manufacturing consumes less energy and water than many alternatives

- End-of-life benefits: Complete biodegradability without environmental harm or microplastic formation

The kraft process removes lignin from wood fibers while preserving long cellulose fibers, using fewer harmful chemicals compared to traditional papermaking. The unbleached nature of natural kraft paper eliminates chlorine entirely from production.

Manufacturing kraft paper consumes less energy and water than many alternative materials. The chemical recovery process generates heat through burning recovered lignin, further reducing energy requirements.

Unlike plastic alternatives, kraft paper doesn’t contribute to persistent pollution or microplastic formation, supporting circular economy principles through complete biodegradability.

How Does Kraft Paper Compare to Alternative Liner Materials?

Despite kraft paper’s advantages, understanding alternative materials helps optimize your packaging strategy for specific applications. Each alternative attempts to address certain market needs but falls short of kraft paper’s comprehensive performance.

Alternative liner materials like recycled testliner, white top testliner, and barrier-coated papers serve specific niches but cannot match kraft paper’s balanced excellence across strength, printability, consistency, and manufacturing compatibility that explains its 95% market dominance.

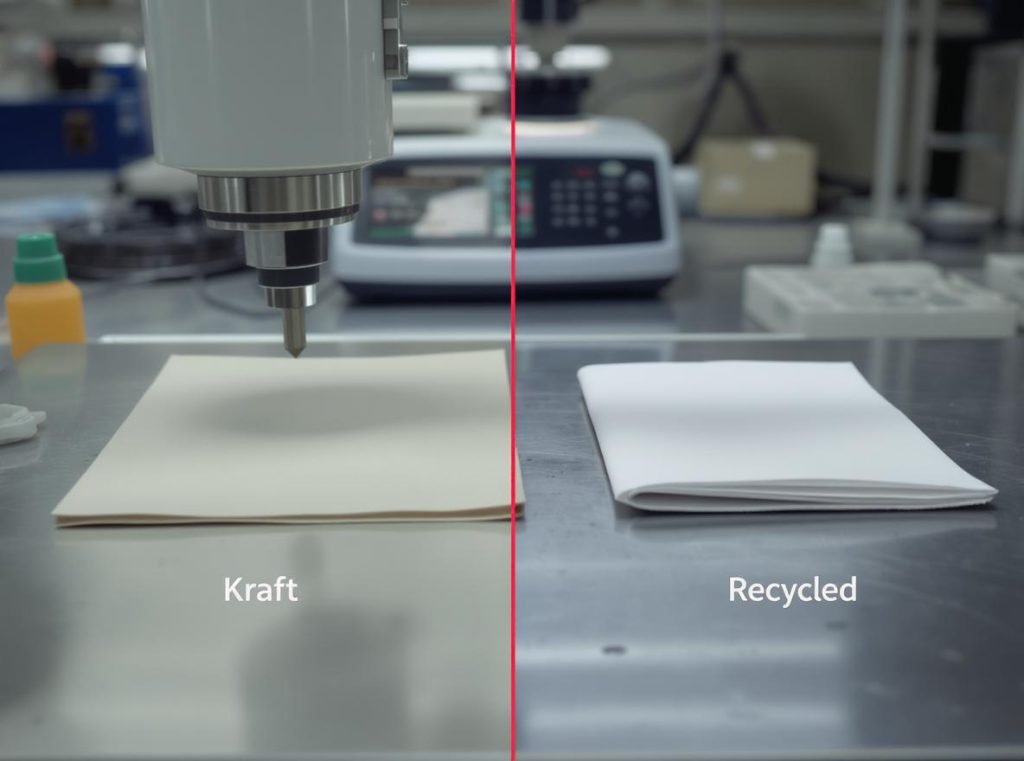

Recycled testliner offers cost savings but compromises strength and consistency. Made primarily from recycled fibers, testliner has shorter fiber lengths that result in lower burst strength and tear resistance.

Alternative material analysis:

Recycled testliner struggles with quality variations between batches, creating manufacturing challenges and potential performance inconsistencies. While suitable for cost-sensitive applications, it cannot match kraft’s performance in demanding scenarios.

White top testliner attempts to combine cost savings with printability but still suffers from fundamental strength limitations of recycled fiber content. The recycled base layer limits overall structural performance.

Barrier-coated papers provide specialized moisture resistance but add cost and complexity while potentially compromising recyclability. These materials serve niche applications but lack kraft paper’s versatility.

| Material Type | Strength Rating | Consistency | Print Quality | Recyclability |

|---|---|---|---|---|

| Virgin Kraft | Excellent | Superior | Outstanding | Excellent |

| Test Liner | Good | Variable | Fair | Good |

| White Top Test | Good | Variable | Good | Good |

| Barrier Coated | Variable | Good | Variable | Limited |

Alternative fiber sources such as agricultural residues face challenges in achieving kraft paper’s combination of strength, consistency, and manufacturing compatibility, explaining why they remain niche solutions.

When Should You Choose Alternative Liner Materials?

Despite kraft paper’s comprehensive advantages, specific applications may benefit from different liner materials. Understanding these scenarios helps optimize your packaging strategy while controlling costs effectively.

Alternative liner materials make sense for non-critical applications where kraft paper’s premium properties aren’t necessary, such as internal shipping containers, short-distance transportation, or temporary packaging where cost optimization takes priority over maximum performance.

The decision matrix involves balancing performance requirements against cost constraints and specific application demands. Not every packaging application requires maximum strength and print quality capabilities.

Cost-sensitive applications include:

Internal packaging and shipping containers that don’t require printing may use testliner or recycled materials effectively. Cost savings can be significant for high-volume applications with minimal handling requirements.

Short-distance shipping reduces the need for maximum strength properties since packages experience less stress during transportation. Regional distribution might use lighter-weight alternatives successfully.

Industrial applications where appearance doesn’t matter can utilize recycled liners effectively. The focus shifts entirely to functional protection rather than presentation or branding requirements.

Temporary packaging for construction, moving, or storage applications often prioritizes cost over performance. Basic recycled liners provide adequate protection at significantly lower costs.

However, these alternatives often require compromises in performance, consistency, or other characteristics that can offset their apparent cost advantages through increased damage rates or processing issues.

Summary

Kraft paper dominates corrugated board manufacturing because it represents 95% of the North American market through its unmatched combination of superior strength, excellent printability, manufacturing efficiency, and environmental sustainability. With burst factors exceeding 32+ BF and projected market growth to $27.75 billion by 2031, kraft paper delivers proven value that alternative materials cannot match comprehensively.

Ready to optimize your packaging strategy with kraft paper’s proven advantages? Contact Acreet today for expert guidance on selecting the right corrugated materials for your specific applications and custom packaging solutions that protect your products while showcasing your brand professionally.