You’ve developed an amazing product, but you’re staring at a blank canvas when it comes to packaging. The thought of creating custom packaging feels overwhelming, and you’re not sure where to begin. Without proper packaging, even the best products can fail to capture customer attention or protect what’s inside during shipping.

The first steps to designing custom packaging include defining your product specifications and brand identity, conducting comprehensive market research including competitor analysis and consumer testing, establishing realistic budgets (typically 10-40% of retail price) and timelines (8-16 weeks), selecting appropriate materials based on functional and sustainability requirements, and creating a detailed design brief with clear project objectives and success metrics.

Ready to transform your product with packaging that not only protects but also sells? Let’s dive into the essential first steps that will set your custom packaging project up for success.

Table of Contents

ToggleWhat Should You Define About Your Product Before Starting the Design Process?

Understanding your product inside and out is crucial before you even think about design aesthetics. This foundational step determines every subsequent decision in your packaging journey.

You need to define your product’s physical characteristics (dimensions, weight, fragility), brand positioning and personality, target audience demographics and psychographics, regulatory compliance requirements, and cultural considerations for international markets. These foundational elements directly influence every design decision and material selection.

Brand Identity and Positioning

Your brand positioning should be clearly defined from the outset. Consider how your packaging will communicate your brand’s values, personality, and story to consumers. Whether you’re positioning as premium, eco-friendly, or value-oriented, every design element should align with this strategic direction.

Document your brand’s personality, visual identity guidelines, and key differentiators from competitors. Include existing marketing materials, logos, and brand assets that should influence the packaging design.

Product Physical Specifications

Start by documenting your product’s physical characteristics including dimensions, weight, fragility, and any special requirements such as temperature sensitivity or regulatory compliance. This information forms the foundation for all subsequent design decisions.

Consider if your product has irregular shapes, sharp edges, or delicate components that need special protection. Think about quantity considerations too – are you packaging single items, sets, or bulk quantities?

Demographic and Psychographic Research

Your packaging speaks directly to your customers before they even touch your product. Demographic and psychographic research is essential for creating packaging that resonates with your customers. Consider factors such as age, gender, income level, lifestyle preferences, and purchasing behaviors.

Different demographics respond to different design elements – millennials may prioritize sustainability messaging, while older consumers might prefer clear, readable information. Cultural considerations also play a significant role, as colors, symbols, and imagery can have different meanings across cultures and regions.

| Customer Type | Packaging Expectations | Key Considerations |

|---|---|---|

| Luxury Buyers | Premium materials, elegant design | High-quality finishes, sophisticated colors |

| Eco-Conscious | Sustainable materials, minimal waste | Recyclable options, biodegradable components |

| Budget-Focused | Cost-effective, functional | Simple design, efficient materials |

| Online Shoppers | Shipping durability, unboxing experience | Protective structure, Instagram-worthy design |

Usage Environment Assessment

Consider where and how your product will be used. Is it a gift item requiring premium presentation? A functional tool needing quick access? An emergency product requiring clear identification?

Weather resistance, shelf life, and storage conditions all impact material selection and design features.

How Do You Conduct Effective Market Research for Packaging Design?

Market research prevents costly mistakes and reveals opportunities that competitors might have missed. This step helps you understand industry standards while identifying ways to differentiate your product.

Effective packaging market research involves visual competitive analysis through systematic photography and cataloging, qualitative research methods like in-depth interviews and focus groups, quantitative testing through surveys and A/B testing, industry trend monitoring, and consumer behavior analysis to understand shopping patterns and decision-making processes.

Visual Competitive Analysis Strategy

Visual competitive analysis involves systematically photographing and cataloging competitor packaging across different product categories, price points, and distribution channels. Create a database of competitor packages using spreadsheets or presentation software.

Key evaluation criteria should include shelf impact, cost considerations, innovation elements, pricing strategies, and performance factors. Look for gaps in the market where your packaging could differentiate itself while avoiding direct copying of successful designs.

Analysis Framework:

- Material choices and structural design

- Color schemes and typography styles

- Information hierarchy and messaging

- Unique selling propositions displayed

- Special finishes and premium features

Consumer Testing and Validation

Qualitative research methods provide deep insights into consumer motivations and preferences. In-depth interviews allow you to observe how consumers interact with packaging in real-time, noting their reactions to texture, weight, and opening mechanisms. Focus groups can reveal collective attitudes toward different design directions.

Quantitative testing methods help validate design decisions at scale. Package testing surveys can measure appeal, purchase intent, and price expectations across different demographic segments. A/B testing allows you to compare multiple design options and identify the most effective approach.

Consumer Testing Methods:

- One-on-one interviews for detailed feedback

- Focus groups for collective insights

- Online surveys for broader data collection

- Prototype testing for functional validation

- Eye-tracking studies for visual attention analysis

Retail Environment Research

Different retail environments have specific requirements. Understanding these early prevents redesign costs later.

E-commerce Considerations:

- Shipping box compatibility

- Damage prevention features

- Return-friendly design

- Sustainable materials preference

Retail Store Requirements:

- Shelf space optimization

- Hanging display compatibility

- Theft prevention features

- Easy restocking design

What Budget and Timeline Considerations Should You Plan For?

Realistic budgeting and timeline planning prevent project delays and cost overruns. Many businesses underestimate the time and investment required for professional packaging development.

Industry standards suggest allocating 10-40% of a product’s retail price to packaging costs, with typical project timelines ranging from 8-16 weeks. Budget for design development (3-5 days for concepts, 1-2 weeks for prototypes), production setup including tooling and materials, and allow extra time for stakeholder reviews and regulatory approvals.

Industry Budget Guidelines

Industry standards suggest allocating 10-40% of a product’s retail price to packaging costs. However, this range varies significantly based on product category, target market, and strategic objectives. Premium products may justify higher packaging investments, while value-oriented products require more cost-conscious approaches.

Understanding where your money goes helps you allocate resources effectively and make informed decisions about where to invest or save.

Design and Development Costs:

- Initial design consultation and strategy

- Concept development and iterations

- Technical drawings and specifications

- Prototype creation and testing

Production Setup Investment:

- Custom die-cutting tools

- Printing plates and color setup

- Quality control processes

- Packaging equipment adjustments

Key Cost Optimization Strategies:

- Right-size packaging to minimize material waste

- Standardize sizes across product lines for economies of scale

- Choose appropriate printing methods (digital for small runs, offset for large volumes)

- Balance special finishes with budget constraints

- Consider sustainable materials for long-term brand value

Material and Manufacturing Expenses:

- Raw material costs per unit

- Printing and finishing processes

- Assembly and quality inspection

- Special finishes like foil stamping and embossing

- Packaging and shipping preparation

Timeline Planning Framework

Typical project timelines range from 8-16 weeks for comprehensive packaging design projects. The design phase alone typically takes 3-5 days for initial concepts, followed by 1-2 weeks for prototype development. Allow extra time for unexpected challenges, regulatory approvals, and stakeholder reviews, as rushed projects are more prone to costly mistakes.

| Phase | Duration | Key Activities |

|---|---|---|

| Research & Planning | 2-3 weeks | Market analysis, brand positioning, requirement gathering |

| Design Development | 3-5 weeks | Concept creation, design refinement, client feedback cycles |

| Prototyping & Testing | 2-3 weeks | Sample creation, functional testing, consumer validation |

| Production Setup | 2-3 weeks | Tooling creation, equipment setup, quality control processes |

| Initial Production | 1-2 weeks | First production run, final adjustments, delivery preparation |

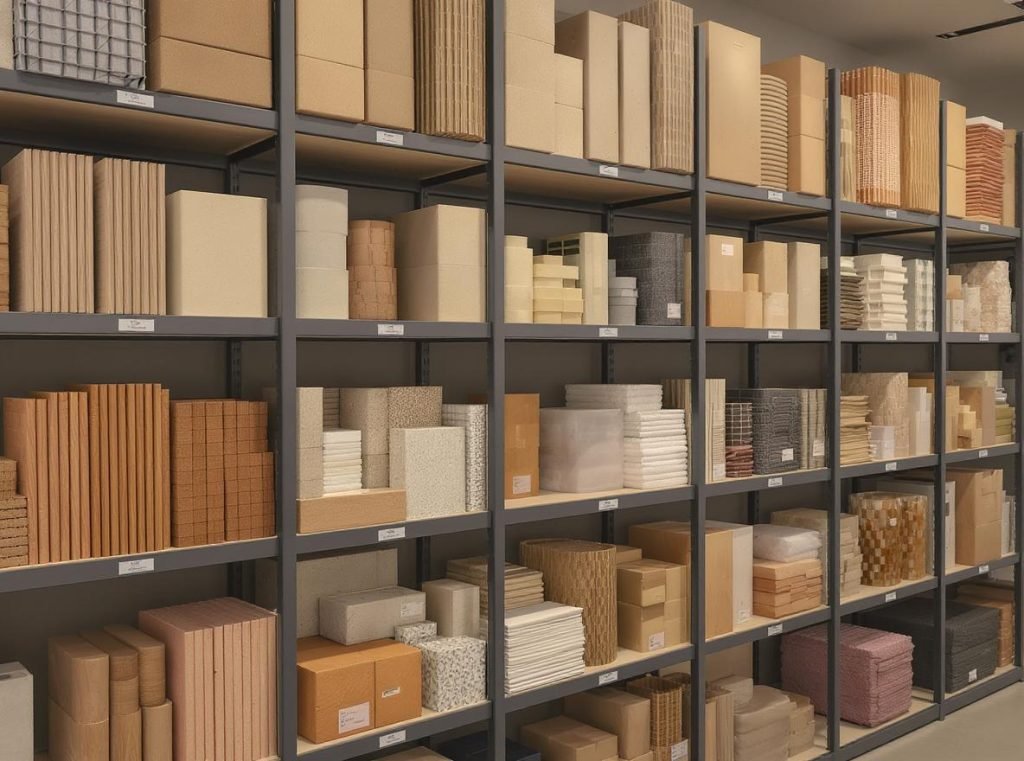

How Do You Choose the Right Packaging Materials and Structure?

Material selection balances protection, cost, sustainability, and brand image. The wrong choice can lead to product damage, customer complaints, or environmental concerns.

Choose packaging materials based on functional requirements including protection needs and shelf life, sustainability considerations with recyclable and biodegradable options, cost analysis across volume considerations, and structural design elements that enhance user experience while maintaining product integrity during shipping and handling.

Functional Requirements Assessment

Functional requirements should drive material selection decisions. Consider your product’s protection needs, shelf life requirements, and transportation conditions. Fragile products need shock-absorbing materials, while food products require appropriate barrier properties.

Key Protection Considerations:

- Shipping and handling durability requirements

- Environmental protection (moisture, light, temperature)

- Tamper evidence and security features

- Regulatory compliance for specific industries

- Child safety considerations where applicable

Each material category serves different purposes and creates distinct brand impressions. Understanding these helps you make informed decisions.

Corrugated Cardboard:

Strong protection for shipping and storage. Excellent for e-commerce and wholesale applications. Cost-effective for larger items.

Folding Cartons:

Lightweight and printable. Perfect for retail shelf display. Good for smaller consumer products.

Rigid Boxes:

Premium feel and appearance. Ideal for luxury items and gift products. Higher cost but impressive unboxing experience.

Flexible Packaging:

Space-efficient and lightweight. Great for food items and products needing moisture protection.

Structural Design Considerations

The packaging structure must serve functional needs while creating positive user experiences. Consider these essential aspects:

- Opening mechanism: Easy access without damaging contents

- Closing system: Secure closure that maintains product integrity

- Internal organization: Proper positioning and protection for components

- Stackability: Efficient storage and transportation

- Display features: Visibility and presentation advantages

Advanced Sustainability Options

Modern consumers increasingly value environmentally responsible packaging. Sustainability considerations are increasingly important to consumers and regulatory bodies. Options include:

Sustainable Material Categories:

- Recyclable materials: Cardboard, glass, aluminum, and certain plastics

- Biodegradable options: Cornstarch-based packaging, seaweed films, and plant-based plastics

- Compostable materials: Paper-based packaging and bio-based polymers

- Reusable designs: Containers that serve secondary purposes after initial use

While sustainable materials may cost more upfront, they can provide long-term brand value and regulatory compliance benefits. Consider your target market’s environmental priorities when making material decisions.

What Information Should Your Design Brief Include?

A comprehensive design brief serves as your project roadmap, ensuring all stakeholders understand goals, requirements, and expectations. This document prevents misunderstandings and keeps the project focused.

Your design brief should include project overview with specific objectives, brand positioning and messaging hierarchy, target consumer profiles with demographic and psychographic data, technical specifications including regulatory requirements, budget parameters and timeline expectations, competitive landscape analysis, and measurable success metrics aligned with business goals.

Strategic Project Foundation

Project overview should clearly identify the product, launch type, target market, and key deadlines. Include specific SKU information and any variants or sub-brands that need consideration. Define what success looks like for your packaging project – whether launching a new product, refreshing an existing brand, or addressing specific market challenges.

Common Project Objectives:

- Increasing shelf visibility and standout

- Communicating product benefits effectively

- Enhancing brand recognition and recall

- Improving user experience and functionality

- Meeting sustainability goals

- Driving purchase intent and sales performance

Brand positioning and messaging sections ensure design alignment with broader brand strategy. Your packaging must seamlessly integrate with your existing brand identity while potentially elevating it.

Detailed Consumer and Market Intelligence

Target consumer profiles should include demographic data, psychographic insights, and behavioral patterns. The more specific you can be about your ideal customer, the more targeted your design can become. Consider shopping patterns, decision-making processes, and pain points that packaging can address.

Competitive landscape analysis helps designers understand market context and differentiation opportunities. Identify key competitors and explain how your packaging should stand apart while avoiding direct copying of successful designs.

Marketing messaging hierarchy prioritizes the most important claims and benefits to feature prominently. Distinguish between hero claims, differentiators, and supporting information to guide design emphasis.

Protection Requirements:

- Shipping and handling durability

- Environmental protection (moisture, light, temperature)

- Tamper evidence or security features

- Child safety considerations

User Experience Needs:

- Ease of opening and closing

- Information accessibility

- Reusability or disposal considerations

- Accessibility for different user groups

Technical Specifications

Include detailed technical requirements to ensure your packaging can be manufactured efficiently and meets industry standards.

Document size constraints, weight limitations, printing specifications, and any special finishing requirements. Include information about quantity needs and delivery schedules.

How Do You Find and Work with the Right Packaging Partner?

Selecting the right packaging manufacturer or design partner significantly impacts your project’s success. The right partner brings expertise, efficiency, and problem-solving capabilities to your project.

Use the “Three C’s” evaluation method: Chemistry (agency understanding of your brand and challenges), Case studies (portfolio breadth and commercial success), and Credentials (unique methodology and expertise). Ask about experience with similar products, design alignment processes, manufacturer collaboration, sustainability integration, and revision handling procedures.

The “Three C’s” Evaluation Method

The “Three C’s” method provides a comprehensive framework for evaluating potential packaging partners:

1. Chemistry: Assess whether the agency understands your brand and business challenges. Look for partners who ask thoughtful questions about your goals rather than immediately pitching their services. This indicates genuine interest in your success.

2. Case Studies: Review the agency’s portfolio for breadth and depth of experience. Diverse industry exposure often leads to more innovative solutions, while too narrow a focus may result in template-driven approaches. Examine not just aesthetic quality but also commercial success and strategic thinking.

3. Credentials: Understand the agency’s unique methodology and areas of expertise. Be wary of agencies that claim proprietary processes that lock you into specific approaches. Look for transparent, collaborative methodologies.

Essential Partnership Questions

Key questions to ask potential packaging partners include:

- Do you have experience with products similar to ours?

- How do you ensure design alignment with brand identity?

- Do you collaborate with manufacturers and printers during the design process?

- How do you incorporate sustainability into your designs?

- What is your process for handling revisions and feedback?

- Can you demonstrate measurable results from previous packaging projects?

- How do you handle budget constraints and timeline pressures?

Technical and Service Capabilities:

- Production equipment and capacity assessment

- Quality control processes and certifications

- Industry-specific knowledge and compliance expertise

- Design and prototyping service offerings

- Post-delivery support and optimization services

Collaboration Best Practices

Clear communication is essential for successful partnerships. Establish regular check-ins, define feedback protocols, and ensure all stakeholders are aligned on project goals and timelines. Communication protocols should establish how feedback will be provided and incorporated throughout the project.

A collaborative approach works best when both parties contribute their expertise. Share your market knowledge and business constraints while allowing the agency to bring creative solutions and technical expertise. Budget transparency helps agencies recommend appropriate solutions – provide realistic budget parameters early in the process.

Success Partnership Elements:

- Regular project reviews and milestone check-ins

- Defined approval processes and stakeholder responsibilities

- Open communication about challenges and opportunities

- Shared commitment to project timeline and quality standards

- Clear documentation of decisions and design rationale

At Acreet, we understand that finding the right packaging partner is crucial for project success. Our “Three C’s” approach ensures we understand your brand chemistry, demonstrate relevant case studies, and bring proven credentials to every project. We collaborate closely with manufacturers and printers to ensure design feasibility while maintaining your timeline and budget requirements.

Ready to begin your custom packaging project? Contact our design team today for a consultation. We’ll work with you to understand your specific needs and create packaging solutions that exceed your expectations while meeting your budget and timeline requirements.

Summary

The first steps to designing custom packaging involve comprehensive preparation and strategic planning. Begin by defining your product specifications and brand identity, then conduct thorough market research including visual competitive analysis and consumer testing. Establish realistic budgets (10-40% of retail price) and timelines (8-16 weeks), select appropriate materials based on functional requirements and sustainability goals, create detailed design briefs with clear objectives and success metrics, and partner with experienced packaging professionals using the “Three C’s” evaluation method. These foundational steps ensure your packaging project delivers results that protect your product while enhancing your brand’s market presence and driving business success.

Ready to begin your custom packaging journey? Contact our design team at Acreet today for a comprehensive consultation. We’ll guide you through each step using our proven methodology, ensuring your packaging project exceeds expectations while meeting your specific business requirements and market objectives.