With growing environmental concerns and stricter regulations, businesses worldwide are questioning their packaging choices. You’re likely wondering if corrugated boxes truly offer the sustainable solution your customers demand while maintaining the durability your products need.

Yes, corrugated boxes are one of the most sustainable and eco-friendly packaging options available today. With a recycling rate of 93.6% as of 2022, they are the most recycled packaging material in the United States. Made from renewable tree fiber, water, and starch, corrugated boxes are 100% biodegradable and compostable, creating a closed-loop system that significantly reduces environmental impact.

Let’s explore why corrugated packaging stands out as the smart choice for environmentally conscious businesses and how it can benefit your bottom line.

Table of Contents

ToggleWhat Makes Corrugated Boxes Environmentally Sustainable?

Understanding the environmental credentials of your packaging helps you make informed decisions that align with your sustainability goals and regulatory requirements.

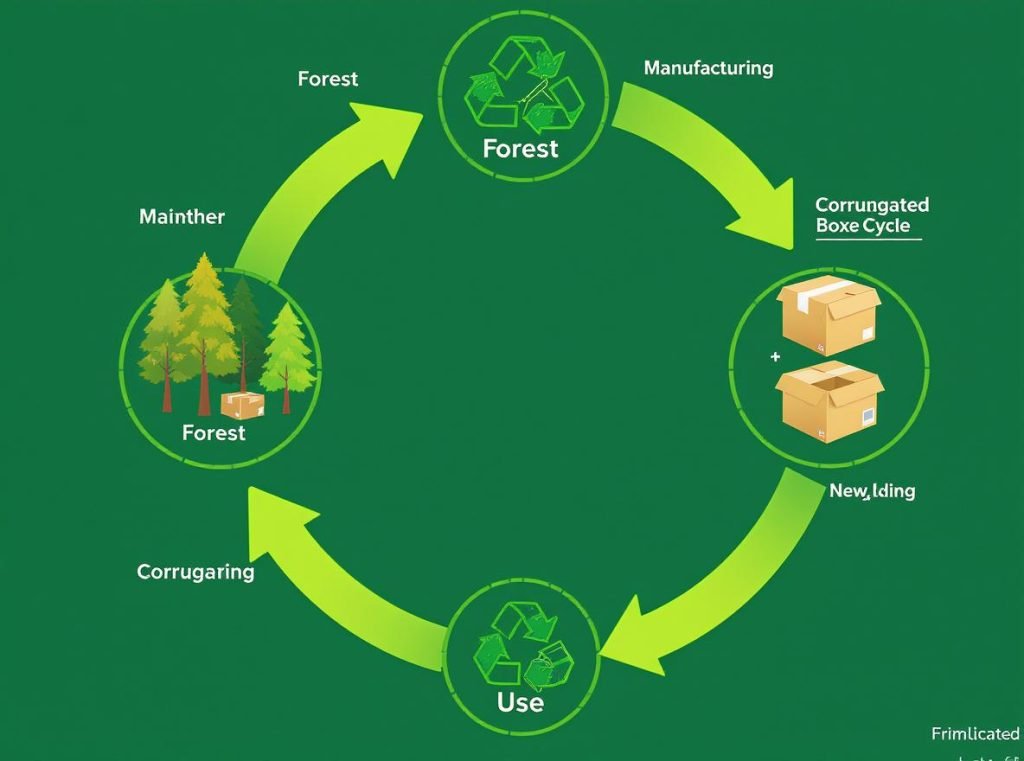

Corrugated boxes excel in sustainability due to their renewable materials, exceptional recycling rates, and complete biodegradability. Made from sustainably managed forests where three trees are planted for every tree harvested, corrugated packaging operates on a circular economy model with 90% of U.S.-sourced wood fiber coming from private landowners following sustainable forestry practices.

The sustainability of corrugated boxes stems from several key factors that set them apart from other packaging materials:

Renewable Resource Foundation: Corrugated cardboard is manufactured from tree fiber sourced from responsibly managed forests. The industry follows sustainable forestry practices where forests are continuously replanted and maintained, ensuring a renewable supply chain that actually contributes to carbon sequestration.

Exceptional Recycled Content: The average industry recycled content is 52%, but custom corrugated boxes can include up to 65% recycled materials while maintaining structural integrity. This high recycled content reduces the demand for virgin materials and minimizes waste in the production cycle.

Complete Biodegradability: Unlike plastic packaging that persists for hundreds of years, corrugated boxes are 100% biodegradable and can decompose naturally in approximately two months. This rapid decomposition ensures minimal environmental impact even when proper disposal isn’t possible.

| Sustainability Feature | Corrugated Boxes | Plastic Packaging | Styrofoam |

|---|---|---|---|

| Renewable Materials | Yes (Tree fiber) | No (Petroleum) | No |

| Recycling Rate | 93.6% | 9% | <1% |

| Biodegradable | Yes (2 months) | No (100+ years) | No |

| Energy from Biomass | 70% | 0% | 0% |

Energy Efficiency: Paper mills generate 70% of their energy from carbon-neutral biomass residuals, utilizing by-products from the paper manufacturing process. This closed-loop energy system significantly reduces fossil fuel dependence compared to plastic production.

The manufacturing process has become increasingly efficient, with modern corrugated production facilities using advanced technologies to minimize water usage and maximize material yield.

How High Are Corrugated Box Recycling Rates?

Recycling rates demonstrate the real-world effectiveness of sustainable packaging materials and their acceptance in established waste management systems.

Corrugated boxes achieve exceptional recycling rates of 93.6% as of 2022, making them the most recycled packaging material in the United States. This rate has consistently improved over decades, with more corrugated boxes recovered for recycling than plastic, glass, steel, and aluminum combined.

The recycling success of corrugated boxes reflects both infrastructure maturity and consumer acceptance:

Historical Performance: The recycling rate has improved dramatically from 54% in 1993 to the current 93.6%, with peak years like 2018 reaching 96.4%. The three-year average recycling rate stands at 91.3%, demonstrating consistent performance.

Infrastructure Support: 94% of Americans have access to community recycling programs that accept corrugated containers, creating a comprehensive collection network that supports high recovery rates.

Fiber Reuse Efficiency: Corrugated boxes can be recycled an average of seven times, with box fibers being reused multiple times to create new packaging materials. Of the 34 million tons recycled annually, 53% (18 million tons) are used to produce new containerboard.

- Well-established collection systems in most communities

- Strong market demand for recycled corrugated materials

- Simple sorting process that doesn’t require complex technology

- Economic incentives for recycling facilities to process corrugated waste

Volume Leadership: Measured by tonnage, corrugated boxes were the most-recycled products and materials in 2018 at 32.1 million tons, leading all other recyclable materials and demonstrating the scale of successful recycling infrastructure.

The high recycling rates aren’t just statistics—they represent real environmental benefits and demonstrate a mature, functioning circular economy for corrugated packaging.

What Are the Carbon Footprint Benefits of Corrugated Packaging?

Understanding the carbon impact of your packaging choices helps you make decisions that support climate goals while maintaining business efficiency and regulatory compliance.

Corrugated packaging has achieved a remarkable 50% per unit reduction in greenhouse gas emissions between 2006 and 2020, representing the most significant environmental improvement among packaging materials. This reduction addresses climate change mitigation more effectively than any other packaging option available to businesses.

The carbon footprint story of corrugated packaging involves comprehensive environmental improvements:

Comprehensive Impact Reductions: The 2020 Life Cycle Assessment revealed substantial improvements across multiple environmental categories beyond just carbon footprint:

- Ozone depletion: 13% reduction

- Energy usage: 13% reduction

- Water usage: 18% reduction

- Acid rain: 41% reduction

- Smog: 44% reduction

- Respiratory effects: 54% reduction

- Eutrophication: 30% reduction

Carbon Sequestration Benefits: Fresh fibers from sustainably managed forests drive carbon dioxide removal from the atmosphere during tree growth. Additionally, recycling old corrugated containers prevents carbon dioxide and methane emissions from landfills, creating a dual benefit for climate protection.

Manufacturing Efficiency: The production process utilizes 70% carbon-neutral biomass energy, reducing dependence on fossil fuels and lowering overall emissions compared to plastic packaging manufacturing.

| Environmental Impact | 2006 Baseline | 2020 Achievement | Improvement |

|---|---|---|---|

| Greenhouse Gas Emissions | 100% | 50% | 50% reduction |

| Water Usage | 100% | 82% | 18% reduction |

| Energy Usage | 100% | 87% | 13% reduction |

| Smog Formation | 100% | 56% | 44% reduction |

Continuous Improvement: The industry’s commitment to scientific measurement and innovation ensures ongoing environmental performance improvements, with new technologies and processes continuing to reduce environmental impact.

Are There Any Drawbacks to Corrugated Box Sustainability?

Every packaging solution has limitations, and understanding these helps you make balanced decisions that consider both environmental goals and practical business requirements.

While corrugated boxes are highly sustainable, they have some limitations including moisture sensitivity, manufacturing resource intensity, and contamination issues that can affect recyclability. However, these drawbacks are manageable with proper planning, design optimization, and sourcing strategies.

Moisture Vulnerability: Corrugated boxes can lose structural integrity when exposed to moisture, with compression strength decreasing by over 30% in humid conditions. This limitation may require additional protective measures for certain products or shipping environments.

Manufacturing Resource Intensity: Corrugated box production is energy-intensive and water-intensive, requiring significant resources for pulp production, mechanical processing, and chemical treatments. Water consumption includes large volumes for pulp washing, processing, and wastewater treatment.

Single-Use Nature: Corrugated packaging is generally not reusable and requires high quantities for one-time use. While highly recyclable, the single-use nature limits direct reuse opportunities compared to reusable plastic containers.

Contamination Challenges: Food contamination or grease can make corrugated boxes unsuitable for recycling. Pizza boxes and other food containers often cannot be recycled due to contamination, reducing the effective recycling rate in food service applications.

| Potential Drawback | Impact Level | Mitigation Solutions |

|---|---|---|

| Moisture Sensitivity | Medium | Moisture-resistant coatings, barrier treatments |

| Resource Intensity | Medium | Biomass energy, closed-loop water systems |

| Single-Use Design | Low | Optimized design, return programs |

| Contamination Risk | Low-Medium | Food-safe barriers, clear recycling guidelines |

Mitigation Strategies: These limitations can be addressed through careful supplier selection, innovative design approaches, and hybrid solutions that optimize both sustainability and functionality.

Modern corrugated manufacturers are continuously developing solutions to address these challenges while maintaining superior environmental performance.

How Do Corrugated Boxes Compare to Other Sustainable Packaging Options?

Making informed packaging decisions requires understanding how corrugated boxes stack up against other eco-friendly alternatives in terms of performance, cost, and environmental impact.

Corrugated boxes demonstrate superior environmental performance compared to most packaging alternatives, offering the best balance of sustainability, functionality, and cost-effectiveness. Recent life cycle assessments show that single-use corrugated cardboard demonstrates lower environmental impact than reusable plastic packaging solutions when considering manufacturing, transportation, and end-of-life factors.

Versus Plastic Packaging: Corrugated boxes significantly outperform plastic across all sustainability metrics:

- Recycling rate: 93.6% vs. 9% for plastic

- Biodegradability: 2 months vs. hundreds of years for plastic

- Raw materials: Renewable vs. non-renewable fossil fuels

- Carbon footprint: 50% reduction achieved vs. higher emissions for plastic

Versus Reusable Plastic Containers (RPCs): Recent studies demonstrate that single-use corrugated packaging often has lower environmental impact than reusable plastic systems due to the energy requirements for cleaning, transportation, and maintenance of reusable systems.

Versus Alternative Sustainable Materials: While materials like molded pulp, biodegradable plastics, and reusable fabric packaging offer sustainability benefits, corrugated boxes maintain advantages in:

- Cost-effectiveness and proven ROI

- Widespread recycling infrastructure availability

- Proven sustainability performance with verified data

- Versatility across different product categories and shipping conditions

| Material | Recycling Rate | Biodegradation | Cost | Infrastructure |

|---|---|---|---|---|

| Corrugated | 93.6% | 2 months | Low | Established |

| Plastic | 9% | 100+ years | Medium | Limited |

| Molded Pulp | 85% | 60 days | Medium | Growing |

| Bioplastics | Variable | Requires industrial composting | High | Limited |

Performance Consistency: Corrugated boxes provide reliable performance across the widest range of applications, temperature conditions, and shipping requirements, making them the most practical choice for diverse business needs.

The combination of proven sustainability credentials, established infrastructure, and cost-effectiveness makes corrugated boxes the gold standard for sustainable packaging.

What Should Businesses Consider When Choosing Sustainable Corrugated Packaging?

Making the right corrugated packaging choice involves balancing sustainability goals with practical business requirements while ensuring regulatory compliance and cost-effectiveness.

Businesses should prioritize certified sustainable sourcing, optimize recycled content levels, implement right-sizing strategies, and select water-based materials when choosing sustainable corrugated packaging. The key is working with suppliers who maintain Sustainable Forestry Initiative (SFI) or Forest Stewardship Council (FSC) certification to ensure responsible forest management.

Certification Standards: Look for suppliers certified by SFI or FSC, which ensure responsible forest management and sustainable fiber sourcing. These certifications guarantee that wood pulp comes from sustainably managed forests where three trees are planted for every tree harvested.

Recycled Content Optimization: Custom corrugated boxes can include up to 65% recycled materials while maintaining structural integrity. Specify higher recycled content percentages when possible, as the average industry recycled content is 52%.

Right-Sizing Strategy: Creating right-sized boxes for products reduces material waste and transportation emissions. Optimized packaging design can reduce carbon footprint by 10% through consolidated shipping and improved cargo space efficiency.

Material Selection: Choose water-based inks and adhesives to eliminate harmful chemicals and enhance recyclability. More corrugated boxes now use recyclable alternative coatings than traditional wax coatings.

- Partner with FSC or SFI certified suppliers

- Specify maximum feasible recycled content

- Implement package design reviews to eliminate waste

- Consider regional sourcing to reduce transportation impact

- Evaluate full lifecycle costs including disposal

Supply Chain Optimization: Local sourcing reduces transportation emissions and supports regional economies. Sourcing 90% of materials from countries where manufacturing occurs optimizes environmental impact and reduces supply chain complexity.

Regulatory Preparedness: Custom corrugated packaging helps businesses stay ahead of evolving regulations targeting single-use plastics, with many regions implementing requirements for 100% recyclability by 2030.

Working with experienced packaging partners who understand both sustainability requirements and practical business needs ensures optimal results.

How Can Custom Corrugated Packaging Enhance Your Sustainability Strategy?

Custom corrugated packaging offers unique opportunities to maximize sustainability benefits while strengthening your brand position and improving operational efficiency.

Custom corrugated packaging allows businesses to optimize material usage, reduce waste, improve supply chain efficiency, and communicate sustainability commitments while maintaining superior environmental performance. Tailored solutions eliminate excess material usage and can reduce transportation emissions by up to 10% through design optimization.

Material Optimization: Custom sizing ensures you use only the corrugated material necessary to protect your products. This approach reduces waste, eliminates void fill requirements, minimizes dimensional weight charges, and lowers overall environmental impact.

Brand Communication: Custom printing with water-based inks allows you to communicate your sustainability commitments directly to customers. This transparency builds trust, differentiates your brand, and supports purchasing decisions, as 72% of American consumers agree that packaging design significantly impacts purchasing decisions.

Supply Chain Integration: Custom packaging enables consolidated shipping, reducing transportation emissions and fuel consumption. Stackable designs maximize cargo space efficiency, while right-sizing reduces the number of shipments required.

Circular Economy Design: Custom corrugated packaging can be designed for optimal recyclability and reuse. Re-engineering packaging components can eliminate non-renewable materials and enhance recyclability while maintaining product protection.

- Incorporate sustainability messaging into package design

- Design for easy disassembly and recycling

- Create packaging that serves multiple purposes

- Implement features that enhance reusability

Cost-Effectiveness: Custom corrugated solutions often provide cost savings through material optimization, reduced shipping expenses, and lower initial costs compared to plastic alternatives, enabling better resource allocation for sustainability initiatives.

Regulatory Compliance: Custom solutions help businesses stay ahead of evolving packaging regulations and consumer expectations, positioning your brand as a sustainability leader in your industry.

Innovation Opportunities: Custom packaging projects often lead to innovative solutions that push the boundaries of sustainable packaging while maintaining cost-effectiveness and operational efficiency.

Acreet’s expertise in custom corrugated packaging helps businesses create solutions that exceed sustainability expectations while supporting brand goals and operational requirements.

Summary

Corrugated boxes represent the gold standard for sustainable packaging, combining exceptional environmental performance with practical functionality and proven cost-effectiveness. With recycling rates of 93.6%, a 50% reduction in greenhouse gas emissions, and complete biodegradability, they offer businesses a scientifically validated path to sustainability that exceeds regulatory requirements and customer expectations.

Ready to enhance your sustainability strategy with custom corrugated packaging solutions? Contact Acreet today to discuss how our expert design team can create packaging that maximizes your environmental benefits while strengthening your brand and optimizing your supply chain. Send us your inquiry and discover the sustainable packaging possibilities that will set your business apart in the marketplace.