Choosing the right packaging for your e-commerce business directly impacts shipping costs, customer satisfaction, and operational efficiency. With padded mailers gaining popularity as an alternative to traditional boxes, you’re likely wondering if they’re the right choice for your products.

Yes, padded mailers are an excellent option for many e-commerce products, offering 20-40% shipping cost savings while providing adequate protection for lightweight, semi-fragile items under 2-3 pounds. They’re ideal for electronics, books, jewelry, and textiles, but unsuitable for extremely fragile or heavy products.

Let’s explore everything you need to know about padded mailers to make the smartest packaging decision for your business.

Table of Contents

ToggleWhat Exactly Are Padded Mailers and How Do They Work?

Many e-commerce businesses confuse padded mailers with regular poly mailers, but understanding their construction is crucial for making informed packaging decisions.

Padded mailers, also known as bubble mailers or cushioned envelopes, feature an outer layer of kraft paper, polyethylene plastic, or recycled paper with built-in cushioning materials like bubble wrap, shredded paper, or honeycomb structures that absorb impacts during shipping.

The multi-layer construction creates effective protection through integrated design. Unlike boxes that require separate padding materials, these mailers combine the envelope structure with protective cushioning in a single package.

Three Main Types Available:

Kraft bubble mailers offer an attractive natural appearance with bubble wrap lining, providing both protection and professional presentation. They’re particularly popular for their eco-friendly look and recyclable properties.

Poly bubble mailers feature plastic polyethylene construction with bubble wrap padding, delivering excellent moisture resistance and durability. These represent the most cost-effective option while offering superior water damage protection.

Paper padded mailers use entirely paper-based materials with shredded paper or honeycomb padding, making them the most environmentally friendly option that’s fully curbside recyclable.

| Mailer Type | Outer Material | Padding | Best For |

|---|---|---|---|

| Kraft Bubble | Kraft Paper | Bubble Wrap | Professional appearance |

| Poly Bubble | Polyethylene | Bubble Wrap | Moisture protection |

| Paper Padded | Recycled Paper | Paper/Honeycomb | Eco-friendly shipping |

Which Products Are Perfect for Padded Mailers?

Industry analysis shows that padded mailers excel with specific product categories while being unsuitable for others.

Padded mailers work perfectly for electronics under 2 pounds, books and media, jewelry and accessories, textiles, and small home goods. They’re unsuitable for large bulky items, extremely fragile glassware, heavy products that could puncture the envelope, or items requiring rigid structural support.

Electronics and Small Devices:

Smartphones, tablets, RAM modules, SSD drives, flash drives, and small electronic accessories benefit tremendously from cushioning protection. The padding absorbs shocks that could damage sensitive components during transit.

Books and Media:

DVDs, Blu-ray discs, thin books, magazines, and printed materials are perfectly matched for padded mailers. The cushioning prevents bending and corner damage that commonly occurs with these items during shipping.

Jewelry and Accessories:

Small jewelry pieces, cosmetics, skincare items, and delicate accessories receive adequate protection in compact padded mailers. The popular 4.5 x 10 inch size works particularly well for jewelry shipments.

Textiles and Soft Goods:

• T-shirts and lightweight apparel

• Gloves, scarves, and accessories

• Fabric samples and materials

• Small craft supplies and notions

Products to Avoid:

Heavy items over 2-3 pounds can burst padded mailer seams. Extremely fragile items like ceramics, glassware, or delicate electronics need boxes for proper protection. Sharp or protruding objects can puncture the envelope, creating security and damage risks.

How Do Padded Mailers Compare to Shipping Boxes?

The cost-versus-protection debate requires understanding specific trade-offs that impact your bottom line and customer satisfaction.

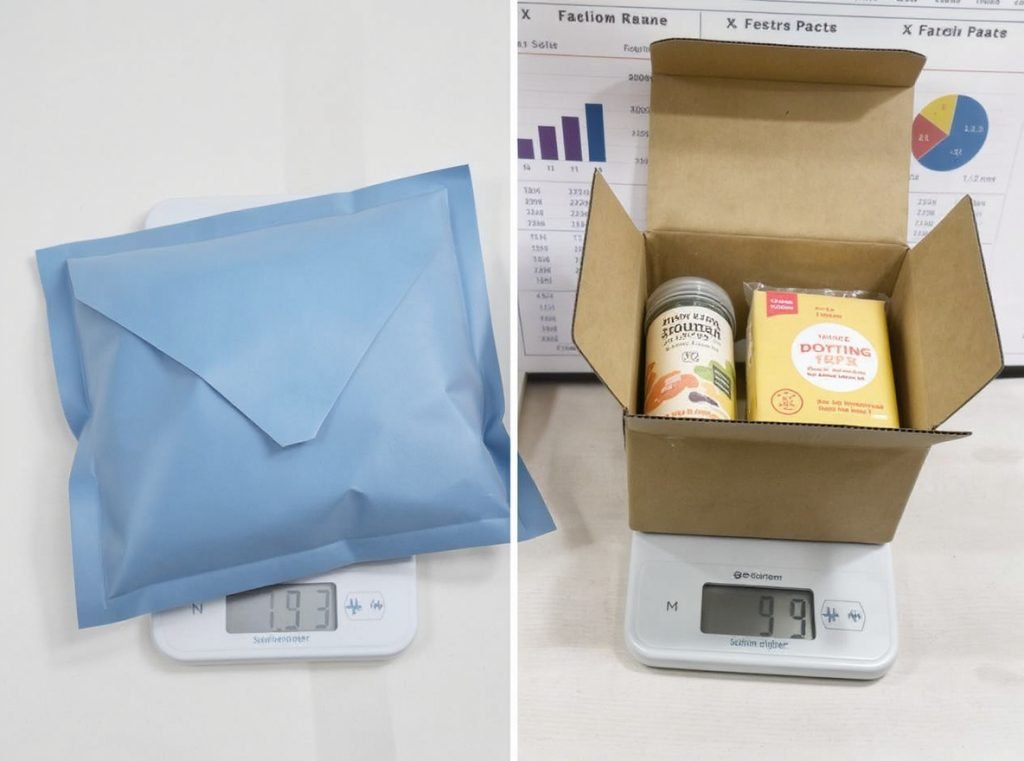

Padded mailers typically weigh 1-4 ounces empty compared to 4-8 ounces for equivalent boxes, resulting in 20-40% shipping cost savings. Material costs range from $0.10-$0.50 per mailer versus $0.30-$1.25 for boxes, while assembly time drops to zero compared to folding and taping boxes.

Comprehensive Comparison:

Weight differences create immediate shipping advantages. Padded mailers maintain compact dimensions that benefit from dimensional weight pricing, especially for lightweight products under one pound.

Protection levels favor boxes for extremely fragile items, but padded mailers provide adequate cushioning for semi-fragile products at significantly lower costs. The key involves matching protection levels to actual product needs rather than over-packaging.

Storage and Operational Efficiency:

Padded mailers ship flat and stack efficiently, requiring minimal warehouse space compared to pre-assembled boxes. Some businesses report 50% faster packing times due to elimination of assembly requirements.

When Boxes Win:

| Situation | Why Boxes Excel |

|---|---|

| Multiple items | Better organization and protection |

| Fragile glassware | Superior rigid protection required |

| Heavy products | Structural integrity for weight support |

| Premium brands | Enhanced unboxing experience |

| Irregular shapes | Custom fitting capabilities |

What Are the Main Benefits of Using Padded Mailers?

Smart e-commerce businesses choose padded mailers for compelling financial and operational advantages that directly impact profitability.

Primary benefits include 20-40% shipping cost reductions, 50% faster packing times, minimal storage requirements, adequate protection for appropriate products, and lower environmental impact. The global padded mailers market, valued at $9.0 billion in 2024, demonstrates growing industry acceptance.

Cost Efficiency Breakdown:

Shipping cost reductions stem from reduced weight and compact dimensions. Businesses shipping lightweight items report significant savings, especially with high-volume operations where every ounce matters for shipping calculations.

Material costs provide immediate advantages. Quality padded mailers cost $0.10-$0.50 per unit in bulk quantities, compared to $0.30-$1.25 for equivalent boxes with padding materials.

Operational Excellence:

Zero assembly time eliminates box folding and taping procedures. High-volume shippers report 50% faster packing times, significantly improving productivity in busy fulfillment operations.

Storage optimization delivers ongoing benefits. Flat-stacked mailers use approximately 75% less warehouse space than equivalent boxes, allowing businesses to stock larger quantities without expanding facilities.

Environmental Advantages:

• Many options contain 50% recycled content

• Paper-based varieties biodegrade naturally

• Reduced material waste compared to oversized boxes

• Lower transportation emissions due to weight savings

• Curbside recyclable in most areas

Professional Presentation:

Quality padded mailers, especially kraft varieties, provide professional unboxing experiences that reinforce brand image without traditional packaging bulk.

Are There Any Drawbacks to Consider?

Every packaging solution has limitations, and understanding padded mailer constraints prevents costly mistakes and customer complaints.

Key drawbacks include limited protection for extremely fragile items, size constraints typically maxing at 14×19 inches, moisture vulnerability with paper varieties, puncture risks from sharp objects, and reduced premium brand perception compared to custom boxes.

Protection Limitations:

While adequate for semi-fragile products, padded mailers cannot match comprehensive protection offered by properly designed box packaging. Drop tests consistently show boxes outperforming mailers for high-impact scenarios.

Physical Constraints:

Standard sizes top out around 14×19 inches for largest varieties, limiting product compatibility. Heavy items stress seams beyond design limits, potentially causing failures during transit.

Environmental Vulnerabilities:

Paper-based mailers can suffer moisture damage, though plastic varieties offer better water resistance. This limitation may prove critical for certain shipping routes or climates.

Security Concerns:

| Risk Factor | Potential Impact | Mitigation Strategy |

|---|---|---|

| Puncture damage | Product contamination | Choose thicker materials |

| Moisture exposure | Product degradation | Use poly varieties |

| Seam failure | Contents spillage | Proper size selection |

| Tampering | Security concerns | Tamper-evident closures |

Single-Use Limitation:

Unlike sturdy shipping boxes that customers often reuse, padded mailers typically serve single-use purposes, though they remain recyclable in most areas.

How Much Do Padded Mailers Actually Cost?

Understanding total cost implications helps you make accurate comparisons and budget decisions for packaging investments.

Standard pricing ranges from $0.10-$0.75 per unit depending on size and material. Small 6×9 inch mailers cost $0.10-$0.25 in bulk, while large 14×19 inch sizes reach $0.35-$0.75. Volume discounts of 30-50% apply for quantities over 1,000 units.

Detailed Pricing Breakdown:

Material differences affect costs significantly. Poly bubble mailers represent the most economical option, while kraft bubble mailers command 20-40% premium pricing for their professional appearance.

Volume purchasing delivers substantial savings. Bulk quantities of 1,000+ units typically achieve 30-50% cost reductions compared to retail pricing, with many suppliers offering case quantities from 100-1,000 pieces.

Hidden Cost Analysis:

Factor in shipping costs for the mailers themselves, storage space requirements, and custom printing expenses. However, these typically get offset by reduced shipping weights and simplified handling procedures.

Total Cost Comparison:

• Small operations (100-500 units): $0.25-$0.45 per mailer

• Medium volume (500-1,000 units): $0.20-$0.35 per mailer

• High volume (1,000-5,000 units): $0.15-$0.30 per mailer

• Enterprise level (5,000+ units): $0.10-$0.25 per mailer

Labor cost reductions often exceed material savings. Eliminating box assembly, separate padding handling, and complex sealing processes can reduce packing labor costs by 40% for appropriate products.

What Should You Look for When Choosing Padded Mailers?

Selecting optimal padded mailers requires evaluating multiple factors to ensure cost-effectiveness, adequate protection, and operational efficiency.

Essential selection criteria include appropriate sizing with 0.25-0.5 inches clearance around products, adequate padding thickness ranging from 1/16″ to 3/16″, strong self-sealing adhesive strips, tear-resistant materials, and environmental considerations aligned with sustainability goals.

Size Selection Strategy:

Measure typical products and add 0.25-0.5 inches to each dimension for proper fit. Standard sizes include 6×9″, 8.5×11″, 10.5×15″, and 14.25×19″ to accommodate most e-commerce items without excessive waste.

Padding Evaluation:

Bubble wrap padding offers maximum protection for fragile items. Shredded paper provides good protection with superior environmental benefits. Honeycomb structures deliver balanced protection and sustainability.

Quality Indicators:

Strong heat-sealed or reinforced seams prevent failures during transit. Tamper-evident sealing strips provide security while tear strips enhance customer unboxing experiences.

Material Durability Assessment:

• Puncture resistance for sharp-edged contents

• Moisture protection for weather exposure

• Seam strength for weight capacity

• Adhesive quality for secure closure

Environmental Considerations:

Choose recycled content materials and ensure end-of-life recyclability aligns with your sustainability commitments. Paper-based options offer the best environmental profile for most applications.

How Can Custom Padded Mailers Enhance Your Brand?

Professional packaging transforms utilitarian shipping into powerful marketing opportunities that reinforce brand identity throughout the customer journey.

Custom padded mailers featuring logos, brand colors, and messaging create professional unboxing experiences while maintaining cost advantages over boxes. Custom printing typically adds $0.05-$0.20 per mailer but delivers ongoing marketing value that justifies investment for established brands.

Branding Opportunities:

Modern printing techniques support full-color designs, spot colors, and special finishes like metallic accents on kraft mailers. Minimum order quantities typically start at 500-1,000 units for custom printing, making it accessible for growing businesses.

Customer Experience Enhancement:

Branded packaging creates anticipation and reinforces brand recognition from shipping notification to doorstep delivery. This enhanced unboxing experience can improve customer satisfaction and encourage repeat purchases.

Design Flexibility Options:

• High-contrast colors for maximum visibility

• Clear logo reproduction and brand messaging

• Social media handles and promotional codes

• Care instructions and sustainability messaging

• QR codes linking to digital experiences

Marketing Value Analysis:

Every package becomes a brand touchpoint that extends marketing reach beyond traditional advertising. The investment in custom printing often pays for itself through improved brand recognition and customer loyalty.

Sustainability Messaging:

Custom mailers provide opportunities to communicate environmental commitments through recyclability symbols and sustainability messaging, appealing to environmentally conscious consumers who value responsible packaging choices.

Summary

Padded mailers offer compelling advantages for e-commerce businesses shipping appropriate products, delivering significant cost savings, operational efficiency, and adequate protection while maintaining professional presentation through customization options.

Ready to optimize your packaging strategy with cost-effective solutions? Contact Acreet today for custom padded mailer solutions tailored to your specific products and shipping requirements. Our packaging experts can help you design branded, protective mailers that reduce costs while enhancing customer experience. Send us your product specifications and volume requirements for a free consultation and competitive quote on custom packaging solutions that drive your business growth.