Businesses worldwide face mounting pressure to adopt sustainable packaging solutions while maintaining premium product presentation. Traditional rigid boxes offer durability and luxury appeal but raise environmental concerns. The challenge lies in finding eco-friendly alternatives that don’t compromise quality or aesthetic standards.

Yes, rigid boxes can absolutely be made from eco-friendly materials. Modern sustainable manufacturing utilizes recycled kraft paperboard, FSC-certified materials, molded pulp components, biodegradable adhesives, and water-based inks. These eco-friendly alternatives maintain identical structural integrity and premium appearance while significantly reducing environmental impact through responsible sourcing and enhanced recyclability.

Let’s explore the comprehensive range of sustainable options available for your custom packaging needs and how they can elevate your brand’s environmental responsibility.

Table of Contents

ToggleWhat Eco-Friendly Materials Are Used in Rigid Box Manufacturing?

Understanding sustainable material options helps businesses make informed packaging decisions. The rigid box industry has revolutionized its approach to incorporate multiple environmentally responsible alternatives without sacrificing performance.

Eco-friendly rigid boxes utilize recycled kraft paperboard (up to 100% post-consumer content), FSC-certified virgin fibers, molded pulp shells from recycled fibers, agricultural waste composites, bamboo fiber materials, water-based adhesives, soy-based inks, and biodegradable barrier coatings. These materials offer identical durability and premium aesthetics while supporting environmental stewardship.

Primary Structural Materials

Recycled kraft paperboard forms the backbone of most sustainable rigid boxes, offering exceptional strength while maintaining a natural, appealing aesthetic. This material utilizes significantly less energy than virgin paperboard production and creates a distinctive natural brown color that eliminates additional bleaching processes.

FSC-certified paperboard ensures responsible forest management with complete supply chain traceability. The Forest Stewardship Council certification guarantees that wood fibers come from forests managed according to strict environmental, social, and economic standards while protecting biodiversity and worker rights.

Molded pulp shells created from 100% recycled fibers provide biodegradable structural components for custom inserts. These materials integrate seamlessly into rigid box designs while maintaining premium presentation standards and complete environmental compatibility.

Innovative Bio-Based Alternatives

| Material Type | Key Benefits | Best Applications |

|---|---|---|

| Agricultural Waste (Wheat Straw, Rice Husks) | Diverts waste, renewable | Food packaging, consumer goods |

| Bamboo Fiber Composites | Fast-growing, superior strength | Luxury items, electronics |

| Algae-Based Materials | Rapid growth, minimal resources | Specialty packaging, cosmetics |

| Mycelium Packaging | Compostable, grown from waste | Protective inserts, cushioning |

These advanced materials often provide superior performance characteristics compared to traditional options. Bamboo grows 35 times faster than trees and regenerates without replanting, while agricultural waste materials transform crop residue into valuable packaging components.

Sustainable Coatings and Finishes

Water-based coatings replace traditional solvent-based finishes while providing necessary moisture and handling protection. These environmentally compatible coatings ensure complete package recyclability while maintaining professional appearance standards.

Biodegradable adhesives eliminate petroleum-based alternatives throughout the assembly process. These plant-based bonding agents provide identical structural integrity while supporting end-of-life compostability and recycling compatibility.

Soy-based inks derived from renewable soybean oil offer vibrant printing capabilities with complete biodegradability. These inks provide excellent color saturation and print quality while supporting agricultural sustainability initiatives.

Are Eco-Friendly Rigid Boxes as Durable as Traditional Ones?

Durability concerns often prevent businesses from adopting sustainable packaging. Modern eco-friendly materials have evolved significantly to address these performance requirements through advanced manufacturing techniques.

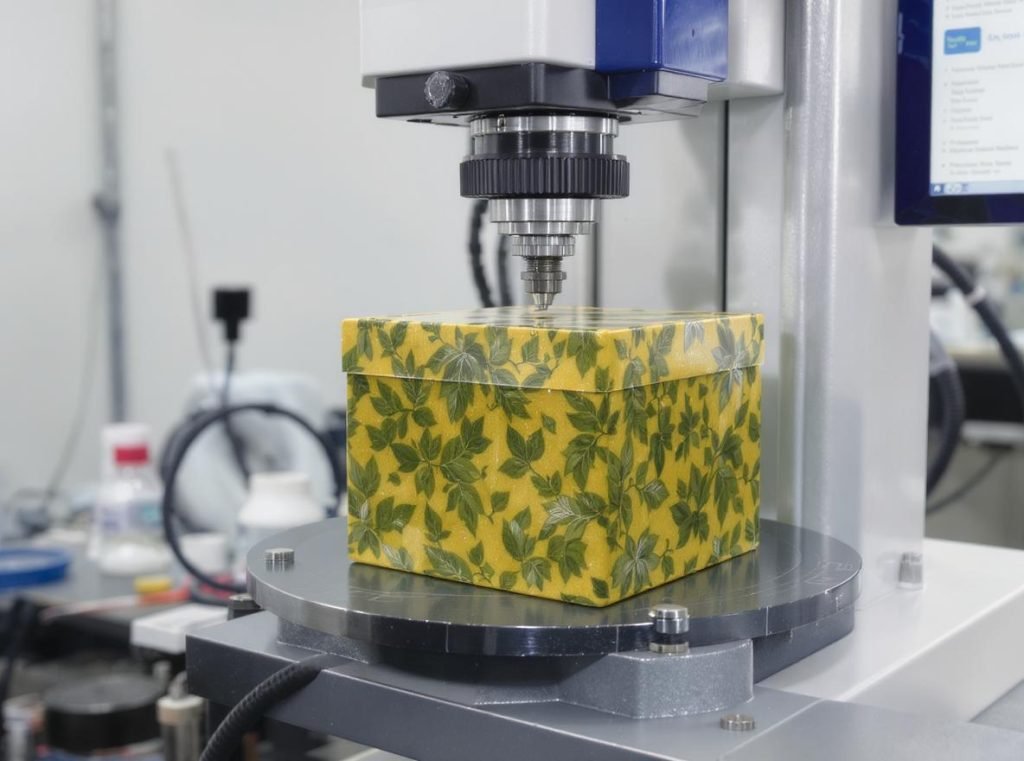

Eco-friendly rigid boxes demonstrate comparable or superior durability to traditional alternatives. Advanced testing confirms that sustainable materials meet identical structural integrity standards including edge crush strength (4-8 kN/m), box compression strength (200-500+ lbs), and burst strength (125-200+ kPa). Recycled fiber structures often provide enhanced tear resistance through improved fiber interlocking.

Performance Testing Results

Rigorous structural integrity assessments evaluate sustainable materials under various stress conditions including vertical loads, lateral pressure, and diagonal forces. These comprehensive tests consistently demonstrate that eco-friendly options maintain their structural properties under challenging real-world conditions.

Environmental durability testing subjects sustainable rigid boxes to extreme temperature fluctuations, humidity variations, and UV exposure. Results indicate that eco-friendly materials often outperform traditional alternatives in challenging environments, particularly when properly engineered and manufactured.

Impact resistance evaluations reveal that sustainable rigid boxes provide excellent product protection during transportation and handling. The natural fiber structure of eco-friendly materials frequently delivers superior shock absorption compared to synthetic alternatives.

Comparative Performance Analysis

- Reusability Rates: Sustainable boxes show 40% higher reuse rates due to consumer preference

- Storage Stability: Enhanced resistance to brittleness and discoloration over time

- Moisture Resistance: Bio-based coatings provide superior barrier properties

- Static Reduction: Natural materials eliminate static electricity buildup issues

The mixed fiber lengths in recycled content create more interlocked structures, often resulting in improved tear resistance compared to virgin materials. Multi-layer construction techniques combine different sustainable materials for optimized performance across all applications.

How Much Do Eco-Friendly Rigid Boxes Cost Compared to Regular Ones?

Cost considerations significantly influence packaging decisions. Understanding the complete economic picture helps businesses evaluate sustainable packaging investments against long-term benefits and market positioning advantages.

Eco-friendly rigid boxes typically cost 10-25% more initially, with basic sustainable options ranging $0.30-$0.65 per unit (5,000-25,000 quantities) versus $0.25-$0.55 for traditional alternatives. However, declining material costs, manufacturing efficiency improvements, and rising traditional packaging expenses are rapidly narrowing this price gap while providing superior brand value and customer loyalty benefits.

Cost Structure Analysis

Material costs represent the primary price difference driver between sustainable and traditional rigid boxes. Sustainable materials require specialized processing and may have limited supplier networks, though these costs decline rapidly as adoption increases and supply chains mature.

Manufacturing costs for eco-friendly rigid boxes generally match traditional alternatives since most sustainable materials process on existing equipment. Some eco-friendly materials actually reduce manufacturing complexity by eliminating chemical treatments or specialized handling requirements.

Volume significantly impacts pricing economics. Large orders of eco-friendly rigid boxes often achieve cost parity with traditional options through manufacturing economies of scale and bulk purchasing advantages.

Long-Term Economic Benefits

| Benefit Category | Economic Impact | Quantifiable Results |

|---|---|---|

| Brand Positioning | Premium pricing support | 15-25% higher product margins |

| Customer Loyalty | Increased repeat purchases | 30% higher retention rates |

| Regulatory Compliance | Avoid future penalties | Proactive cost avoidance |

| Supply Chain Stability | Diversified material sources | Reduced price volatility risk |

Companies implementing sustainable packaging report increased customer engagement scores and higher brand perception metrics. Consumer willingness to pay premium prices for environmentally responsible brands continues growing across global markets, particularly among younger demographics.

The global sustainable packaging market, valued at $117.54 billion in 2024 and projected to reach $240.52 billion by 2034, demonstrates growing economic viability. This expansion drives continued cost reductions through improved economies of scale and technological advancement.

What Certifications Should You Look for in Sustainable Rigid Boxes?

Navigating sustainability claims requires understanding legitimate third-party certifications versus marketing statements. Proper certifications provide verifiable evidence of environmental performance and responsible sourcing practices.

Essential certifications include FSC (Forest Stewardship Council), PEFC (Programme for Endorsement of Forest Certification), SFI (Sustainable Forestry Initiative), TUV Austria compostability, BPI industrial compostability, and Cradle to Cradle lifecycle assessment. These verify responsible sourcing, recyclability, biodegradability, and comprehensive environmental impact while providing market credibility and consumer trust.

Forest Management Certifications

Forest Stewardship Council (FSC) certification represents the gold standard for responsible forest management. FSC provides three categories: FSC 100% (virgin certified forests), FSC Recycled (100% recycled content), and FSC Mix (combination of certified and recycled sources) with complete supply chain traceability.

Programme for the Endorsement of Forest Certification (PEFC) offers alternative framework recognizing national and regional forest certification schemes. PEFC emphasizes local adaptation of sustainable forestry practices while maintaining international environmental standards.

Sustainable Forestry Initiative (SFI) focuses on North American forestry practices, promoting sustainable forest management that protects biodiversity, water quality, and wildlife habitat while supporting local communities and economic development.

Compostability and Biodegradability Standards

TUV Austria Certification provides both home and industrial compostability verification. Home compostable certification requires complete breakdown within 180 days in home composting conditions, while industrial certification addresses controlled composting environments.

Biodegradable Products Institute (BPI) certification focuses on industrial compostability meeting ASTM D6400 standards. BPI-certified products are accepted by commercial composting facilities throughout the United States market.

OK Compost Certification issued by TÜV AUSTRIA provides European-standard verification including both home (OK Compost HOME) and industrial (OK Compost INDUSTRIAL) variants for different end-of-life scenarios.

Comprehensive Environmental Assessment

| Certification Type | Verification Focus | Key Market Benefits |

|---|---|---|

| Cradle to Cradle | Complete lifecycle assessment | Holistic sustainability credibility |

| ISO 14001 | Environmental management systems | Manufacturing process assurance |

| Carbon Neutral | Verified emission offsetting | Climate impact mitigation |

| Blue Angel (Germany) | Comprehensive environmental standards | European market credibility |

These certifications provide transparency for both B2B buyers and end consumers while supporting corporate sustainability reporting requirements and regulatory compliance objectives.

Can Eco-Friendly Rigid Boxes Be Recycled After Use?

End-of-life disposal significantly impacts packaging sustainability. Understanding recyclability helps businesses and consumers make responsible choices while supporting circular economy principles and waste reduction goals.

Most eco-friendly rigid boxes are fully recyclable through standard municipal paper recycling programs. Paper-based sustainable boxes integrate seamlessly into existing recycling infrastructure with 94% population access in developed markets. Water-based inks and biodegradable adhesives enhance recyclability while paper fibers maintain integrity through 4-6 recycling cycles before becoming too short for reuse.

Recycling Process Integration

The established recycling process for paper-based eco-friendly rigid boxes involves collection, sorting, shredding, pulping, filtering, and processing into new paper products. This well-developed infrastructure supports high recovery rates exceeding 70% in Europe and North America.

Municipal recycling programs typically accept sustainable rigid boxes without special preparation beyond flattening for space efficiency. Labels and minimal adhesive amounts don’t require removal since these materials filter out during standard recycling processing.

Water-based inks and biodegradable adhesives used in eco-friendly manufacturing support recycling by eliminating contaminants that could compromise recycled fiber quality. These materials enhance rather than hinder the recycling process effectiveness.

Design for Recyclability Optimization

Mono-material designs using single recyclable material types perform best in existing recycling systems. These designs eliminate complex separation processes while ensuring all components recycle effectively together without contamination issues.

Advanced eco-friendly rigid boxes incorporate design principles specifically optimizing recyclability including material compatibility, adhesive selection, and finishing techniques that support rather than hinder recycling infrastructure capabilities.

Alternative End-of-Life Options

- Home Composting: Certified compostable materials break down in backyard systems

- Industrial Composting: Commercial facilities process certified biodegradable components

- Reuse Applications: Durable construction supports multiple use cycles for storage

- Upcycling Opportunities: Creative repurposing extends packaging lifecycle significantly

The reusability of attractive eco-friendly rigid boxes provides additional environmental benefits as consumers frequently repurpose them for storage, organization, or gift applications, effectively extending packaging lifecycle and reducing new material demand.

What Are the Latest Innovations in Sustainable Rigid Box Materials?

The sustainable packaging industry experiences rapid innovation with breakthrough materials and technologies continuously emerging. Staying informed about cutting-edge developments helps businesses adopt advanced solutions that provide competitive advantages.

Recent innovations include mycelium-based packaging grown from agricultural waste, algae-derived films requiring minimal resources, BASF’s ecovio® certified compostable biopolymers, microfibrillated cellulose barrier coatings, agricultural waste composites from agave and tomato processing, and smart packaging integration combining sustainability with digital functionality. These materials maintain premium aesthetics while providing enhanced environmental performance.

Bio-Based Material Breakthroughs

Mycelium packaging utilizes fungal root structures grown from agricultural waste to create compostable packaging forms requiring minimal energy production. Companies like Ecovative Design pioneer mycelium composites that decompose naturally without harmful residues while providing excellent protective properties.

Algae-based packaging materials represent promising developments utilizing rapidly growing organisms with minimal resource requirements. Algae processes into various packaging components including films, coatings, and structural elements while providing complete biodegradability.

Agricultural waste materials increasingly create sustainable packaging components. Agave fibers from tequila production waste process into strong, durable materials, while initiatives like POMOPLA2 utilize tomato production waste for biodegradable packaging applications.

Advanced Polymer Technologies

BASF’s ecovio® combines biodegradable polyesters PBAT and PLA creating certified compostable materials with performance characteristics matching traditional plastics. These biopolymers process on standard manufacturing equipment while offering industrial compostability verification.

Microfibrillated Cellulose (MFC) technology creates superior barrier properties for packaging applications while maintaining complete biodegradability. MFC applies as coatings or incorporates into structural materials providing enhanced performance characteristics.

Plant-based bioplastics derived from corn starch, sugarcane, and renewable resources provide versatile alternatives offering similar functionality to petroleum-based materials with improved end-of-life options and reduced carbon footprints.

Smart and Functional Innovations

| Innovation Category | Technology Examples | Applications |

|---|---|---|

| Nano-Enhanced Materials | Improved barrier properties | Extended shelf life products |

| Smart Integration | Digital freshness indicators | Temperature-sensitive items |

| Circular Systems | Closed-loop manufacturing | Continuous recycling capability |

| Waste-to-Energy | Beneficial disposal options | Non-recyclable material recovery |

These innovations combine environmental responsibility with enhanced functionality, creating packaging solutions that exceed traditional performance while providing superior sustainability outcomes and consumer engagement opportunities.

How Do You Choose the Right Eco-Friendly Material for Your Product?

Selecting optimal sustainable materials requires balancing product protection needs, brand positioning goals, cost constraints, and environmental objectives. Strategic material selection ensures packaging performance while supporting sustainability commitments effectively.

Choose materials based on product protection requirements, target market expectations, sustainability priorities, and supply chain considerations. Heavy products need recycled greyboard or bamboo composites for structural strength, while luxury items benefit from FSC-certified materials for premium appearance. Consider customer disposal infrastructure, regulatory requirements, and long-term cost implications when making selection decisions.

Product-Specific Assessment Criteria

Product protection requirements form the foundation of material selection decisions. Heavy products require enhanced structural strength favoring recycled greyboard or bamboo fiber composites that provide excellent crush resistance and shipping protection capabilities.

Fragile electronics or glassware benefit from cushioning properties in agricultural waste composites that absorb impact while maintaining structural integrity throughout distribution and handling processes.

Moisture-sensitive products need barrier protection through bio-based coatings or specialized sustainable laminates preventing humidity penetration while maintaining environmental compatibility and recyclability standards.

Market Positioning Considerations

| Market Segment | Recommended Materials | Strategic Benefits |

|---|---|---|

| Luxury/Premium | FSC virgin fiber, bamboo | Premium aesthetics, sustainability story |

| Mass Market | High recycled content | Cost efficiency, environmental appeal |

| Eco-Conscious | 100% recycled/compostable | Maximum sustainability impact |

| B2B/Industrial | Durable recycled greyboard | Protection focus, cost optimization |

Consumer education plays crucial roles in material selection success. Brands targeting environmentally conscious consumers should choose materials with clear sustainability narratives that resonate with their values and purchasing motivations.

Performance and Economic Optimization

Total cost of ownership analysis considers purchase price, handling requirements, transportation efficiency, and end-of-life disposal costs. This comprehensive approach often reveals economic advantages of sustainable materials despite higher initial investment requirements.

Supply chain risk assessment evaluates material supply reliability and stability. Established materials with multiple suppliers offer greater supply security while newer innovations may provide competitive advantages despite higher supply risk factors.

Testing programs validate theoretical material properties under real-world conditions through prototype development ensuring selected materials meet all performance requirements before full-scale implementation and market introduction.

Summary

Eco-friendly rigid boxes successfully combine environmental responsibility with premium packaging performance through advanced sustainable materials and manufacturing processes. From recycled paperboard to innovative bio-based alternatives, modern sustainable options provide durability, aesthetics, and functionality required for diverse applications while supporting circular economy principles and regulatory compliance objectives.

Ready to transform your packaging with sustainable solutions that enhance brand image while protecting the environment? Contact Acreet today for expert consultation on eco-friendly rigid box design and manufacturing. Our experienced team helps international businesses achieve sustainability goals through custom packaging solutions that deliver exceptional product protection, premium presentation, and measurable environmental benefits for long-term competitive advantage.