Temperature excursions cost businesses billions annually, with up to 20% of temperature-sensitive products compromised during transit. Your cold chain integrity depends on choosing the right protective packaging solutions.

Yes, insulated pouches are readily available and widely used for cold chain applications across multiple industries. These specialized thermal packaging solutions maintain precise temperature ranges from -80°C to +25°C for durations of 24-120 hours, making them essential for pharmaceuticals, food delivery, biotechnology, and healthcare sectors.

Let’s explore how insulated pouches can protect your temperature-sensitive shipments and boost your bottom line.

Table of Contents

ToggleWhat Are Insulated Pouches for Cold Chain Applications?

Understanding these thermal protection systems helps you make informed packaging decisions for your temperature-sensitive products.

Insulated pouches are lightweight, flexible packaging solutions specifically designed to maintain temperature-controlled environments during transportation of temperature-sensitive goods. These thermal mailers combine advanced insulation materials with protective barriers to create controlled microenvironments that protect products from external temperature fluctuations.

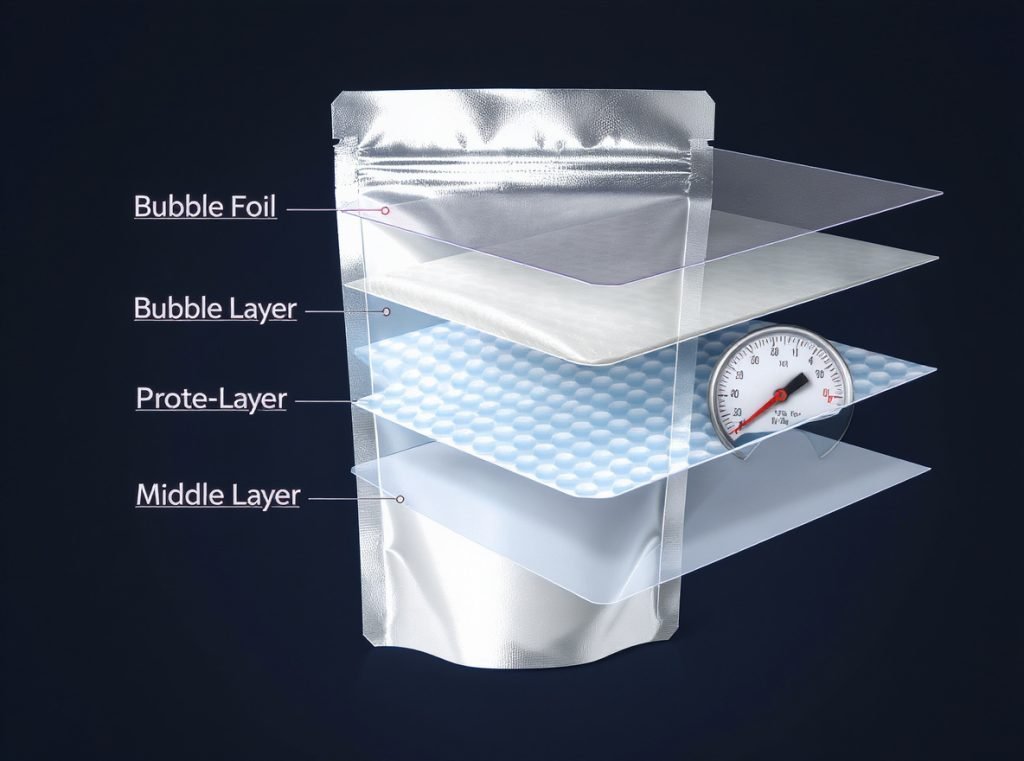

Modern insulated pouches work by creating multiple thermal barriers that slow heat transfer through conduction, convection, and radiation. The combination of insulation and reflective properties enables them to maintain stable internal temperatures for extended periods, even when exposed to extreme external conditions.

Key components include:

- Insulating core materials like polyurethane foam, recycled paper fibers, or natural wool

- Reflective barrier films that deflect radiant heat transfer

- Protective outer layers providing durability and moisture resistance

- Secure closure systems including peel-and-seal adhesive strips or zip-lock mechanisms

The pharmaceutical industry has seen a 50% increase in heat-sensitive medicines over the past eight years, making these pouches essential for maintaining cold chain compliance and protecting valuable shipments.

Which Industries Commonly Use Insulated Pouches?

Multiple sectors rely on insulated pouches to maintain product quality, safety, and regulatory compliance.

The pharmaceutical industry leads in insulated pouch usage, representing 35% of the market share, followed by food and beverage at 30%. Healthcare, biotechnology, and agricultural sectors also depend heavily on these thermal protection solutions.

Pharmaceutical Industry Applications

Critical for transporting vaccines, insulin, biologics, and specialty medications requiring strict temperature control between 2-8°C. With heat-sensitive medicines increasing dramatically, insulated pouches have become essential for GDP compliance and protecting high-value pharmaceutical shipments.

Food and Beverage Sector

The growing trend of online food ordering and home delivery services has significantly increased demand for thermal packaging solutions. Applications include meal kit delivery, fresh produce, dairy products, and frozen foods requiring temperature maintenance during last-mile delivery.

| Industry | Market Share | Common Products | Temperature Range |

|---|---|---|---|

| Pharmaceuticals | 35% | Vaccines, insulin, biologics | 2-8°C, -20°C, -80°C |

| Food & Beverage | 30% | Meal kits, frozen foods, dairy | -18°C to 4°C |

| Healthcare | 20% | Blood samples, medical devices | 2-8°C |

| Biotechnology | 10% | Cell therapies, research materials | 2-8°C, -80°C |

| Agriculture | 5% | Seeds, plant materials | 0-15°C |

Healthcare and Medical Applications

Hospitals, clinics, and medical facilities use insulated pouches to transport blood samples, organs, medical devices, and temperature-sensitive diagnostic materials between facilities.

Biotechnology and Life Sciences

Companies in this sector rely on insulated pouches for shipping cell therapies, gene therapies, and research materials that require ultra-precise temperature maintenance for regulatory compliance and product viability.

What Types of Insulated Pouches Are Available?

Different pouch designs serve various cold chain applications, temperature requirements, and sustainability goals.

Insulated pouches come in multiple configurations including polyurethane foam pouches, paper-based eco-friendly options, foil-bubble thermal mailers, and natural wool pouches. Each type offers distinct advantages for specific temperature ranges, shipping durations, and environmental considerations.

By Material Construction:

Polyurethane Foam Pouches offer superior thermal protection with ultra-insulating foam interiors containing millions of air pockets. These provide the highest performance for extreme temperature requirements and extended shipping durations up to 120 hours.

Paper-Based Pouches utilize recycled paper fibers for eco-conscious businesses. These fully curbside recyclable options provide effective temperature control while meeting sustainability goals without compromising performance.

Foil Bubble Pouches feature reflective outer layers combined with bubble insulation. They’re cost-effective solutions for moderate temperature requirements and shorter transit times of 24-48 hours.

Natural Wool Pouches use 100% natural wool fibers for high-performance insulation with excellent environmental credentials, appealing to brands prioritizing sustainability.

By Performance Capability:

- Single-layer pouches: 12-24 hours protection

- Multi-layer systems: 48-96 hours protection

- Advanced hybrid designs: 120+ hours protection

By Size Configuration:

- Small pouches for medications and samples

- Medium pouches for pharmaceutical products and meal components

- Large pouches for bulk shipments and multiple-item packages

The choice depends on your specific temperature range, transit duration, product value, and environmental goals.

How Do Insulated Pouches Compare to Traditional Packaging?

Performance and cost analysis reveals significant advantages over conventional cold chain packaging methods.

Insulated pouches offer superior cost efficiency, environmental benefits, and operational advantages compared to expanded polystyrene (EPS) coolers and traditional packaging, while providing comparable or better thermal performance with 75% space savings.

Cost Efficiency Advantages

Medium-sized insulated pouches range from $4.00-$5.50 compared to EPS coolers at $5.00-$7.00, providing comparable or better performance at competitive pricing. The total cost of ownership often favors pouches due to reusability and operational efficiencies.

Environmental Impact Benefits

- Insulated pouches are reusable and often made from recyclable materials

- Traditional EPS coolers create significant landfill waste

- Many pouches can be returned through manufacturer incentive programs

- Reduced carbon footprint through compressed shipping and storage

Space and Operational Efficiency

Insulated pouches provide 75% space savings compared to rigid coolers during storage and transportation, translating to significant warehousing and shipping cost reductions. They can be shipped compressed and expand when opened, unlike bulky traditional coolers.

Performance Advantages:

- Better thermal resistance without excessive bulk

- Superior cushioning through elastic foam panels

- Moisture resistance and leak-proof designs

- Professional presentation that maintains brand image

- Faster packing times with no assembly required

Operational Benefits:

- Easier handling and storage

- No multi-component assembly

- Reduced labor costs

- Professional appearance enhances customer experience

Working with experienced packaging manufacturers like Acreet ensures you get optimal solutions that balance performance, cost, and sustainability for your specific cold chain requirements.

What Temperature Ranges Can Insulated Pouches Maintain?

Temperature capabilities vary based on pouch construction, coolant integration, and external conditions.

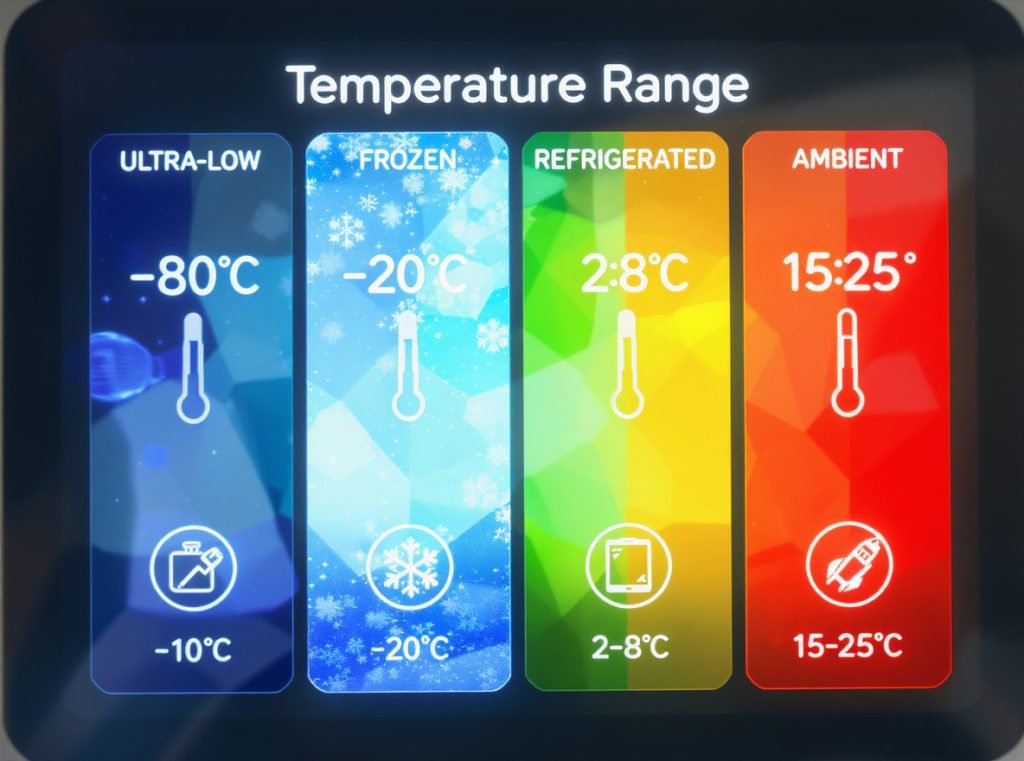

Insulated pouches are engineered to maintain specific temperature ranges from -80°C to +25°C for durations ranging from 24-120 hours, depending on construction technology, coolant selection, and environmental conditions.

Refrigerated Range (2-8°C / 35-46°F)

The most common range for pharmaceutical cold chain requirements, maintaining temperatures for 24-120 hours depending on pouch design. Essential for vaccines, insulin, biologics, and fresh foods requiring strict temperature control.

Frozen Range (-20°C and below / -4°F and below)

Suitable for frozen foods, ice cream, and specialty biologics requiring sub-zero storage. Duration typically ranges from 24-72 hours with appropriate coolant systems.

Controlled Room Temperature (15-25°C / 59-77°F)

Protects general pharmaceuticals, electronics, and industrial chemicals from temperature extremes for 24-48 hours, ensuring product stability during transit.

Ultra-Low Temperature (-80°C / -112°F)

Specialized applications for advanced therapeutics, research samples, and specialty biologics requiring extreme cold storage for 24-48 hours.

Performance Factors:

- External ambient conditions significantly impact duration

- Payload size affects thermal mass and protection time

- Coolant selection determines achievable temperature ranges

- Package handling frequency influences temperature stability

Manufacturers typically provide performance data for various seasonal conditions and shipping lane profiles, helping you select appropriate solutions for your specific routes and requirements.

How Do You Choose the Right Insulated Pouch?

Selecting optimal pouches requires evaluating multiple factors specific to your application and business requirements.

Choose based on exact temperature requirements, transit duration, product characteristics, regulatory compliance needs, shipping conditions, and total cost of ownership rather than just initial purchase price.

Critical Selection Factors

Temperature and Duration Requirements

Determine the exact temperature range your product requires and maximum acceptable deviation. Calculate total shipping time including potential delays, then choose pouches with performance capabilities exceeding your maximum expected transit time by at least 20% for safety margins.

Product Characteristics Assessment

Consider product size, weight, fragility, and sensitivity to temperature fluctuations. Some products may require additional cushioning or shock protection beyond thermal control, influencing your packaging selection.

Regulatory Compliance Evaluation

Ensure selected pouches meet industry-specific regulations such as FDA requirements for pharmaceutical shipping, USDA guidelines for food products, or WHO Good Distribution Practice standards for international shipments.

Shipping Conditions Analysis

- Seasonal ambient temperatures along shipping routes

- Geographic climate variations

- Transportation methods and handling procedures

- Potential delay scenarios and contingency planning

Performance Validation Requirements

Request thermal performance data from potential suppliers including:

- ISTA 7D/7E qualification testing results

- Lane-specific validation studies

- Temperature mapping under various conditions

- Regulatory compliance documentation

Economic Considerations

Balance initial packaging costs against potential product losses, expedited shipping fees, and regulatory penalties for temperature excursions. Consider reusable options for better long-term value despite higher initial costs.

What Are the Cost Considerations for Insulated Pouches?

Understanding comprehensive pricing factors helps optimize your packaging investment and total cost of ownership.

Insulated pouches typically cost $2.50-$8.00 per unit depending on size, materials, and insulation technology, but often provide better total cost of ownership through reduced product losses, shipping efficiencies, and operational savings.

Initial Investment Analysis

While insulated pouches cost more upfront than traditional packaging, this investment often pays for itself through reduced product losses and shipping efficiencies. The key is evaluating total cost of ownership rather than just purchase price.

Long-term Savings Opportunities

- Reusability: Many pouches can be used multiple times with manufacturer return incentive programs

- Shipping efficiency: Better insulation enables standard ground shipping instead of expensive overnight services

- Product protection: Effective temperature control reduces waste from temperature excursions

- Space optimization: 75% space savings reduce warehouse and transportation costs

Volume Pricing Structure

Most manufacturers offer significant price reductions for bulk orders:

- Small quantities (100-500 units): Premium pricing

- Medium volumes (1,000-5,000): Moderate pricing

- Large orders (10,000+): Best unit costs available

- Annual contracts: Additional 5-15% cost savings possible

Hidden Cost Considerations

- Coolant expenses adding $1-5 per shipment

- Staff training on proper packing procedures

- Temperature monitoring and documentation systems

- Regulatory compliance and validation costs

Custom vs. Standard Solutions

Standard sizes offer lower costs and faster delivery, while custom solutions provide optimal performance but require higher minimum orders (typically 1,000-5,000 pieces) and longer lead times of 2-4 weeks.

When calculating true costs, factor in product replacement costs due to temperature damage, regulatory compliance penalties, customer satisfaction impacts, and environmental disposal costs.

Where Can You Source Quality Insulated Pouches?

Reliable suppliers ensure consistent performance and regulatory compliance for your cold chain requirements.

Quality insulated pouches are available from specialized cold chain manufacturers, custom packaging companies like Acreet, and industrial packaging distributors, with custom manufacturers often providing the best value for ongoing requirements and specific applications.

Specialized Cold Chain Manufacturers

Leading companies focus exclusively on temperature-controlled packaging and offer:

- Extensive product lines for various applications

- Technical support and performance validation services

- Regulatory compliance assistance and documentation

- Custom design and manufacturing capabilities

- Comprehensive testing including ISTA qualification protocols

Custom Packaging Manufacturers

Companies like Acreet specialize in creating tailored solutions for specific business needs. We can design insulated pouches that perfectly match your product dimensions, performance specifications, and branding requirements while ensuring cost-effectiveness and reliable performance.

Distribution Channels

- Direct from manufacturers: Best for custom requirements and large volume orders

- Packaging distributors: Offer multiple brand options and smaller quantities

- Specialty cold chain suppliers: Provide comprehensive cold chain solutions

- Regional suppliers: May offer faster delivery and personalized service

Supplier Evaluation Criteria

When selecting suppliers, consider:

- Manufacturing quality certifications (ISO, FDA, cGMP compliance)

- Testing capabilities and validation services

- Custom design and engineering expertise

- Technical support throughout implementation

- Supply chain reliability and consistent lead times

- Geographic coverage and shipping capabilities

- Competitive pricing for your volume requirements

Procurement Best Practices

Request samples and consider running pilot programs before committing to large orders. This approach helps verify performance, identify optimization opportunities, and ensure compatibility with your existing operations.

At Acreet, we provide comprehensive cold chain packaging solutions with custom design capabilities, regulatory compliance support, and competitive pricing for businesses of all sizes.

What Regulatory Requirements Apply to Insulated Pouches?

Compliance requirements vary by industry and geographic region, with strict documentation and validation standards.

Pharmaceutical applications must meet FDA Good Distribution Practice requirements and WHO guidelines, while food applications need HACCP compliance and FDA food contact approvals. All industries require comprehensive documentation and performance validation.

FDA Pharmaceutical Regulations

The Food and Drug Administration oversees pharmaceutical packaging under Title 21 CFR Part 211, requiring:

- Packaging materials suitable for intended use without affecting product quality

- Validated packaging systems with comprehensive performance data

- FDA-approved raw materials for any food contact applications

- Chemical compatibility testing and stability documentation

Good Distribution Practice (GDP) Compliance

Both FDA and European Medicines Agency mandate GDP compliance including:

- Proper temperature monitoring and comprehensive documentation

- Validated packaging systems with performance data for specific shipping lanes

- Staff training on proper handling procedures and protocols

- Risk assessment and mitigation strategies for temperature excursions

Material and Safety Standards

Insulated pouches must use FDA-approved raw materials when used with pharmaceutical or food products, meeting specifications for:

- Chemical compatibility with transported products

- Non-toxicity and safety standards under normal use conditions

- Stability under various storage and transport conditions

- Proper labeling and handling instructions

Documentation Requirements

Regulatory compliance demands comprehensive documentation including:

- Thermal validation studies with lane-specific performance data

- Continuous temperature monitoring records throughout transit

- Packaging integrity testing results and failure analysis

- Chain of custody documentation and audit trails

- Deviation reports and corrective action plans

International Standards

- WHO Good Distribution Practice guidelines for global pharmaceutical distribution

- USP <1079> guidelines for temperature-sensitive products in the United States

- 21 CFR Part 11 requirements for digital monitoring and electronic records

- IATA guidelines for air transportation with dry ice or other coolants

Working with experienced packaging partners helps ensure compliance while minimizing regulatory risks and administrative burden for your organization.

Can Insulated Pouches Be Customized for Specific Needs?

Extensive customization options provide optimal solutions for unique applications and business requirements.

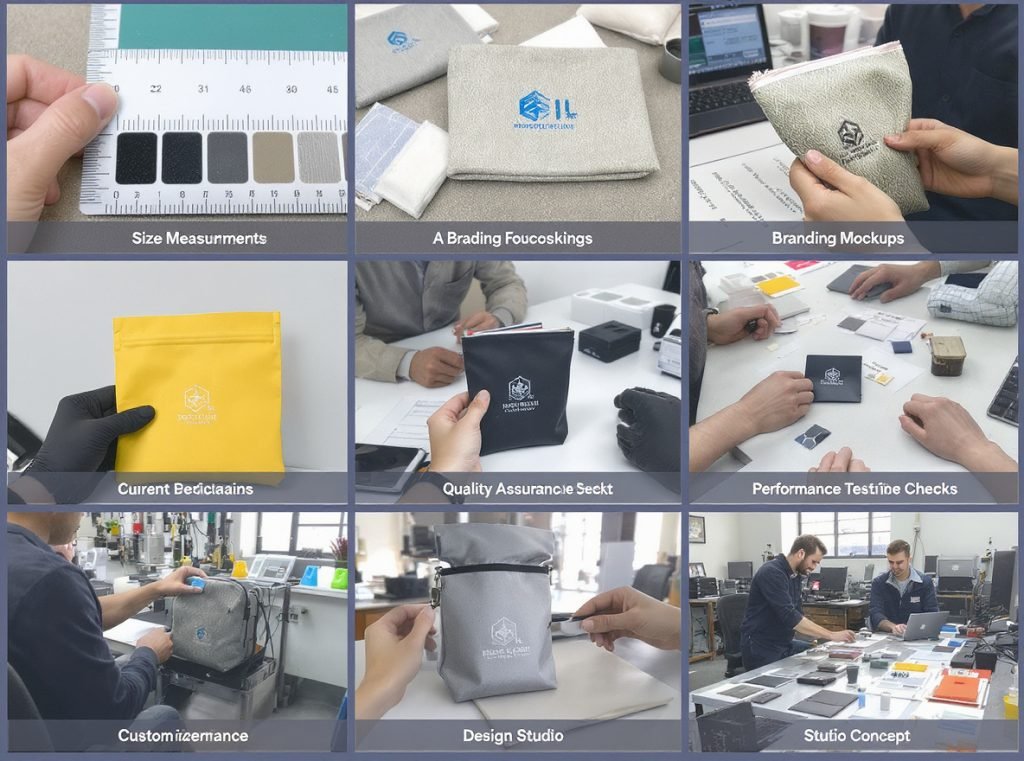

Yes, insulated pouches can be fully customized for size, shape, thermal performance, materials, branding, and special features to match specific product requirements and business needs. Most manufacturers offer custom design services with no additional tooling costs.

Size and Shape Customization

Manufacturers can produce pouches in any custom dimensions to fit specific products or shipping containers. This optimization ensures maximum thermal efficiency, minimal waste space, and improved cost-effectiveness for your applications.

Material and Performance Options

- Insulation thickness: From standard to ultra-high-performance with 1-inch thick panels

- Temperature capabilities: Engineered for specific temperature ranges and durations

- Closure systems: Peel-and-seal adhesive strips, zip-lock closures, or Velcro systems

- Outer materials: Various films for different durability and moisture resistance requirements

Branding and Professional Presentation

Custom printing capabilities include:

- Company logos and professional branding elements

- Handling instructions and safety information

- Product identification and tracking systems

- Temperature indicator integration for visual monitoring

- Professional appearance enhancing customer experience

Advanced Features

Specialized customizations might include:

- Temperature indicator labels showing temperature history

- Tamper-evident seals for security-sensitive applications

- Easy-open features improving user experience

- Sustainable materials meeting environmental goals

- Integration with monitoring and tracking systems

Testing and Validation

Custom pouches undergo comprehensive testing including:

- ISTA 7D/7E qualification protocols

- Lane-specific validation for shipping routes

- Regulatory compliance testing and documentation

- Performance optimization for specific applications

Minimum Orders and Lead Times

Most manufacturers require minimum orders of 1,000-5,000 pieces for custom solutions, with lead times typically ranging from 2-4 weeks for standard customizations and 4-6 weeks for complex designs.

At Acreet, we specialize in creating custom insulated pouches that perfectly match your requirements while maintaining cost-effectiveness, regulatory compliance, and superior performance for your cold chain applications.

Summary

Insulated pouches provide proven, cost-effective solutions for cold chain product protection across pharmaceutical, food, healthcare, and biotechnology industries. With temperature capabilities from -80°C to +25°C and protection durations up to 120 hours, these flexible packaging solutions offer superior performance compared to traditional methods while reducing costs and environmental impact.

Whether you need standard solutions or custom-designed pouches for specific applications, partnering with experienced manufacturers ensures optimal performance, regulatory compliance, and long-term value. Contact Acreet today to discuss how our custom packaging expertise can create the perfect insulated pouch solution for your unique cold chain requirements.