Shipping damage costs businesses billions annually, with fragile products facing the highest risk during transit. Whether you’re dealing with electronics, glassware, or delicate consumer goods, one damaged shipment can destroy customer relationships and hurt your bottom line.

Custom foam and molded pulp inserts provide superior protection by precisely conforming to your product’s shape, absorbing shock, and preventing movement during shipping. These tailored solutions reduce damage rates by up to 85% compared to generic packaging materials, with documented cases showing damage reduction from 36% to zero through proper implementation.

Let’s explore how these protective packaging solutions can safeguard your goods and boost customer satisfaction.

Table of Contents

ToggleWhat Are Custom Foam Inserts and How Do They Work?

Understanding the mechanics behind foam protection helps you choose the right solution for your products. These inserts aren’t just padding—they’re engineered barriers against shipping damage.

Custom foam inserts are precision-cut protective materials designed to cradle specific products with exact dimensional accuracy. They work by creating a custom-fit barrier that absorbs shock energy and eliminates movement within packaging during transit through their cellular structure.

The manufacturing process involves several sophisticated steps. Engineers create detailed CAD drawings based on product specifications, considering exact dimensions, depth requirements, and accessory cutouts. Different foam types are selected based on product weight and fragility requirements.

Key foam material options include:

- Polyurethane (PU) Foam: Soft and flexible, ideal for lightweight equipment

- Polyethylene (PE) Foam: Dense and rigid, best for heavy-duty applications

- EVA Foam: Semi-rigid with excellent shock absorption for electronics

- Anti-Static Foam: Protects against electrostatic discharge for sensitive components

| Cutting Method | Pressure/Power | Best For | Precision Level |

|---|---|---|---|

| Waterjet Cutting | 30,000-90,000 psi | Intricate shapes | Extremely high |

| Die Cutting | Steel rule dies | High-volume production | High |

| CNC Routing | Computer-controlled | Complex designs | Very high |

| Laser Cutting | Focused laser beam | Small, detailed inserts | Extremely high |

Protection mechanisms work through multiple layers. The cellular structure of foam absorbs and disperses kinetic energy during impacts, while vibration dampening reduces harmful vibrations that could damage sensitive products. Custom contouring minimizes product movement and eliminates empty spaces within packaging, and certain foam types provide protection against temperature fluctuations.

What Is Molded Pulp and Why Is It Gaining Popularity?

Molded pulp represents a sustainable revolution in protective packaging, combining environmental responsibility with reliable product protection.

Molded pulp is an eco-friendly packaging material made from recycled paper products, including cardboard, newspapers, and plant-based fibers. This sustainable alternative to plastic packaging provides superior protective properties while being 100% recyclable and biodegradable within 90 days.

The manufacturing process involves several sophisticated stages. Raw material preparation begins with shredding recycled paper products and mixing them with water to form a slurry. This mixture undergoes screening and refinement to remove impurities.

The molding stage uses prepared pulp poured into molds and shaped using vacuum or pressure techniques. Two primary methods exist:

- Wet Press: Creates stronger, more durable products with smooth surfaces

- Dry Press: More cost-effective but less sturdy option

Advanced drying methods improve strength and durability while maintaining lightweight properties. The result is a material that offers compelling environmental advantages.

Environmental benefits drive market adoption:

- Biodegradability: Unlike plastic, molded pulp decomposes naturally within 90 days under proper conditions

- Recyclability: Products are 100% recyclable through standard paper recycling streams

- Renewable Resources: Made from widely available recycled materials

- Lower Carbon Footprint: Production requires less energy compared to plastic manufacturing

Market growth reflects this environmental shift. The molded pulp packaging market is projected to surge from $6.02 billion in 2024 to $12.34 billion by 2034, with a CAGR of 7.45%. This expansion is driven by increasing environmental awareness and cost-effectiveness considerations.

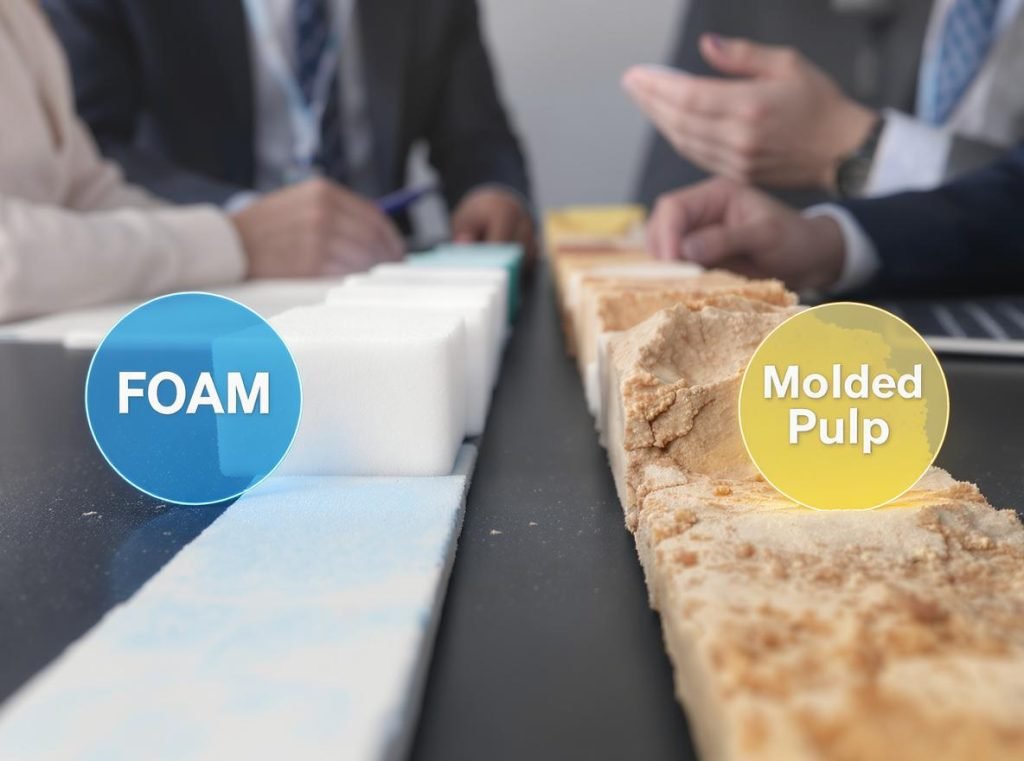

How Do Foam and Molded Pulp Inserts Compare in Protection Performance?

Both foam and molded pulp inserts offer effective protection, but their performance characteristics differ significantly across various applications.

Foam inserts excel at protecting fragile, lightweight items through superior shock absorption and vibration dampening, while molded pulp provides better structural support and edge protection for heavier products, with both materials offering comparable impact protection for most applications.

Mechanical properties reveal distinct strengths. Foam inserts provide superior shock absorption through their cellular structure, excellent vibration dampening capabilities, precise custom-fit capability shaped to product contours, and flexibility that maintains protective properties under various conditions.

Molded pulp inserts offer good mechanical properties and structural strength, excellent edge protection and structural support for fragile items, effective impact absorption during transit, and dimensional stability that maintains shape under normal conditions.

Performance comparison across key factors:

| Protection Factor | Foam Inserts | Molded Pulp Inserts | Optimal Use |

|---|---|---|---|

| Shock Absorption | Excellent | Good | Foam for fragile items |

| Structural Support | Moderate | Excellent | Molded pulp for heavy items |

| Edge Protection | Good | Excellent | Molded pulp for corners |

| Weight Capacity | Light to medium | Medium to heavy | Depends on product |

| Environmental Impact | Higher | Lower | Molded pulp for sustainability |

Weight and density comparison shows foam is generally lighter due to cellular structure, with densities varying by type. Molded pulp is heavier than foam due to fiber density, but offers honeycomb load capability of up to 50kg/m².

Cost analysis reveals different economic profiles. Foam has medium-high raw material costs, medium energy use, low recycling value, and high environmental impact. Molded pulp features low-medium raw material costs, medium energy use, high recycling value, and low environmental impact.

What Products Benefit Most from Custom Foam Insert Protection?

Custom foam inserts excel in protecting high-value, fragile, and precision-sensitive products across multiple industries.

Electronics, medical devices, precision instruments, aerospace components, and high-value consumer goods benefit most from custom foam inserts due to their fragility, sensitivity to vibration, electrostatic discharge concerns, and need for exact dimensional protection.

Electronics and technology represent the largest market segment. Computer components like motherboards, RAM, and processors require ESD protection, while aerospace electronics including avionics and radar systems need specialized cushioning. Medical devices such as high-tech diagnostic equipment demand precision protection, and consumer electronics like smartphones, tablets, and cameras require custom-fit solutions.

Specialized requirements for electronics include:

- Anti-Static Properties: ESD foam prevents electrostatic discharge damage

- Thermal Protection: Insulation against temperature fluctuations

- Precision Fit: Exact dimensional accuracy for delicate components

- Vibration Control: Critical for sensitive electronic circuits

Professional equipment applications span multiple sectors. Military and defense applications include weapons systems, tactical equipment, communication devices, and optical instruments. Medical and healthcare uses encompass surgical instruments, diagnostic equipment, and laboratory devices. Industrial tools require protection for precision measuring instruments, calibration equipment, and sensitive machinery components.

High-value consumer goods also benefit significantly:

- Luxury Items: Jewelry, watches, collectibles, and artwork

- Sporting Goods: Professional equipment requiring exact positioning

- Audio Equipment: High-end speakers, amplifiers, and recording devices

- Optical Instruments: Cameras, lenses, and precision viewing equipment

The automotive industry increasingly relies on foam inserts for shipping electronic components, with modern vehicles containing hundreds of electronic parts that require protection during distribution to assembly plants worldwide.

Which Products Are Best Suited for Molded Pulp Insert Protection?

Molded pulp inserts are particularly effective for lightweight products, consumer goods, and applications requiring sustainable packaging solutions.

Bottled beverages, food products, lightweight electronics, cosmetics, and e-commerce goods benefit most from molded pulp inserts due to their structural support requirements, sustainability mandates, and cost-effectiveness for medium-volume production.

The food and beverage industry represents a primary market. Wine and spirits benefit from stackable, shock-absorbing protection for bottles, while food containers including takeout containers, trays, and clamshells utilize molded pulp’s food-safe properties. Produce packaging for fruits, vegetables, and egg cartons leverages the material’s breathability, and beverage carriers for coffee cups and bottle carriers benefit from structural strength.

Food industry advantages include:

- Food Safety: Non-toxic, safe for direct food contact

- Moisture Management: Can be treated for water resistance

- Stackability: Efficient storage and transport

- Regulatory Compliance: Meets FDA requirements for food contact

Cosmetics and personal care applications have grown significantly. Glass containers including bottles, jars, and fragile packaging benefit from molded pulp’s protective properties. Gift sets for skincare and cosmetic collections use the material’s premium appearance, while eco-friendly products leverage sustainability messaging.

Benefits for cosmetics include:

- Premium Appearance: Wet-press technology creates smooth, polished finishes

- Brand Alignment: Supports sustainability messaging

- Custom Branding: Embossed logos and designs possible

- Protection: Excellent for glass and fragile components

| Product Category | Weight Range | Key Benefits | Market Growth |

|---|---|---|---|

| Beverages | 0.5-2 kg | Stackability, moisture resistance | High |

| Electronics | 0.1-1 kg | Static neutral, lightweight | Medium |

| Cosmetics | 0.1-0.5 kg | Premium appearance, eco-friendly | High |

| Food Products | 0.2-1 kg | Food safety, biodegradable | Very High |

E-commerce and retail applications continue expanding. Online retailers use molded pulp for fragile goods shipping protection, gift packaging benefits from premium presentation capabilities, and general merchandise protection offers cost-effective solutions for various products.

How Do Custom Inserts Reduce Shipping Damage and Returns?

Custom inserts dramatically reduce shipping damage through precision engineering and superior protection mechanisms, with documented cases showing damage reduction from 36% to zero.

Custom inserts reduce shipping damage by 60-85% through elimination of product movement, superior impact absorption, and vibration control. This translates to significant cost savings from reduced returns, replacement costs, and improved customer satisfaction.

Real-world case studies demonstrate dramatic improvements. A manufacturing company documented significant results after implementing custom foam inserts. Before implementation, they experienced a 36% damage claim rate from customers, high replacement costs, and customer satisfaction issues. After implementation, they achieved zero damage claims, eliminated customer complaints, reduced replacement costs, and improved customer satisfaction.

Damage prevention mechanisms work through multiple approaches:

Elimination of Movement: Custom-fit design prevents products from shifting during transit, reduces impact from handling and transportation stresses, and maintains product position throughout the shipping cycle.

Impact Absorption: Superior cushioning materials absorb shock energy, distributed force protection prevents localized damage, and multi-directional impact protection guards against various impact angles.

Vibration Control: Dampens harmful vibrations during transport, prevents cumulative damage from prolonged exposure, and maintains product integrity over long distances.

Cost savings categories include multiple areas:

- Lower Replacement Costs: Reduced need for product replacements

- Reduced Shipping Costs: Fewer return shipments required

- Decreased Processing Costs: Less labor for return handling

- Improved Customer Retention: Enhanced satisfaction reduces churn

| Shipping Method | Damage Rate Without Inserts | Damage Rate With Custom Inserts | Cost Savings |

|---|---|---|---|

| Ground shipping | 12-15% | 2-4% | 75-80% reduction |

| Express shipping | 18-22% | 3-6% | 70-75% reduction |

| International | 25-30% | 5-8% | 70-75% reduction |

Additional benefits extend beyond damage reduction. Professional presentation enhances the unboxing experience, brand protection maintains product integrity and company reputation, and operational efficiency reduces customer service workload.

What Are the Cost Considerations for Custom Foam vs Molded Pulp?

The cost analysis between custom foam and molded pulp involves multiple factors including material costs, manufacturing expenses, and lifecycle considerations.

Custom foam typically costs $0.50-$3.00 per unit with higher tooling costs, while molded pulp ranges from $0.30-$2.50 per unit with lower setup costs for high-volume production. Total cost of ownership must include environmental fees, damage reduction benefits, and long-term sustainability compliance.

Material cost comparison shows significant differences. Molded pulp offers raw material advantages at $50-150 per ton versus $800-1,200 per ton for plastic alternatives. Recycling fees are lower for molded pulp due to standard paper recycling streams, and resource stability provides less volatile pricing due to recycled material base.

Foam costs vary by application. Material costs depend on foam type and density, with processing costs ranging $210-350 per unit. Tooling costs require higher initial investment for custom molds, ranging $1,500-3,000 for basic tooling.

Manufacturing cost analysis reveals:

| Cost Factor | Molded Pulp | Custom Foam | Advantage |

|---|---|---|---|

| Raw Materials | $280-420 | $400-600 | Molded pulp |

| Processing | $210-350 | $300-500 | Molded pulp |

| Mold Costs | $2,800+ | $1,500-3,000 | Foam (initial) |

| Environmental Fees | Low | Medium-High | Molded pulp |

| Volume Economics | Better at scale | Flexible volumes | Depends on quantity |

Long-term economic considerations favor different solutions based on application. Molded pulp benefits include 40% more compact shipping in some applications, stackable design that reduces storage costs, lower risk of environmental penalties, and scale economics of $91-140/ton at volume production.

Foam considerations include longer service life in reusable applications, higher protection value for sensitive items, and greater design flexibility for complex shapes.

A packaging switch case study from foam to molded pulp resulted in $75,000 annual savings, including $30,000 in warehouse savings from 16.7% volume reduction and $45,000 in material savings from lower costs, plus added value through sustainability benefits.

How to Choose Between Foam and Molded Pulp for Your Specific Needs?

The selection between foam and molded pulp should be based on product characteristics, protection requirements, environmental considerations, and cost objectives.

Choose custom foam for fragile, high-value products requiring maximum shock absorption and ESD protection, especially with irregular shapes or low-volume production. Select molded pulp for lightweight to medium-weight items, high-volume production, sustainability requirements, or food-contact applications.

Product assessment criteria guide the decision process. Weight and size considerations show heavy products may require foam’s superior structural support, while lightweight items benefit from molded pulp’s adequate protection with environmental benefits. Size constraints favor custom foam for more precise space utilization.

Fragility analysis reveals highly fragile items need foam inserts with superior shock absorption, moderately fragile products can use molded pulp with good structural support, and robust products can use either option based on other criteria.

Value assessment considerations:

- High-Value Items: Foam’s superior protection justifies higher costs

- Standard Products: Molded pulp offers cost-effective protection

- Volume Considerations: Scale affects optimal material choice

- Regulatory Requirements: Food contact favors molded pulp

Environmental and regulatory factors increasingly influence decisions. EU regulations favor recyclable materials, eco-conscious brands benefit from molded pulp’s sustainability positioning, and packaging waste regulations are increasingly strict across global markets.

Decision framework guidelines:

Choose Custom Foam When:

- Products require ESD protection (electronics)

- Maximum cushioning is essential

- Precision fit is critical

- Reusable packaging is needed

- High-value items justify premium protection

- Irregular shapes require custom solutions

Choose Molded Pulp When:

- Sustainability is a priority

- Cost optimization is essential

- Products are lightweight to medium weight

- Food contact applications are required

- Regulatory compliance demands eco-friendly options

- High-volume production enables economies of scale

| Decision Factor | Foam Advantage | Molded Pulp Advantage | Neutral |

|---|---|---|---|

| Product Value | High-value items | Standard products | Medium-value |

| Fragility | Extremely fragile | Moderately fragile | Robust items |

| Volume | Low-medium volume | High volume | Medium volume |

| Sustainability | Traditional approach | Eco-requirements | Balanced approach |

| Regulations | Flexible compliance | Strict eco-mandates | Standard compliance |

Implementation considerations include prototype testing to validate protection performance, drop testing to simulate real-world shipping conditions, environmental testing to assess performance under various conditions, and cost analysis to compare total lifecycle costs.

Supply chain factors affect the decision. Distribution method considerations include direct-to-consumer versus retail channels, shipping distance factors where long-distance shipments may favor foam, handling requirements in warehouses and fulfillment processes, and volume requirements where scale affects material selection and costs.

Summary

Custom foam and molded pulp inserts provide essential protection for shipping goods, with foam excelling for fragile, high-value items requiring maximum shock absorption and molded pulp offering sustainable, cost-effective solutions for lightweight to medium-weight products. The choice depends on product characteristics, volume requirements, environmental priorities, and regulatory compliance, but both options significantly reduce shipping damage and improve customer satisfaction.

Ready to protect your products with custom inserts? Contact Acreet today for expert packaging design consultation and custom box solutions tailored to your specific needs. Our experienced team can help you choose the optimal insert material and design for maximum protection and cost efficiency while meeting your sustainability goals.