Choosing the wrong manufacturing partner can derail your entire supply chain, leading to missed deadlines, quality disasters, and damaged customer relationships. Before committing to any factory, you need concrete evidence they can deliver what they promise.

Assessing a factory’s production capacity involves evaluating design capacity versus effective capacity, analyzing equipment utilization rates, reviewing workforce capabilities, and validating claims through systematic documentation review. Key metrics include Overall Equipment Effectiveness (OEE), first pass yield rates, and bottleneck identification to determine realistic production capabilities.

Understanding how to properly assess manufacturing capacity protects your business from costly supply chain failures and ensures reliable production partnerships.

Table of Contents

ToggleWhat Are the Key Indicators of a Factory’s Production Capacity?

Production capacity assessment requires understanding both theoretical maximums and real-world limitations that affect actual output.

Key indicators include design capacity (theoretical maximum), effective capacity (realistic output accounting for constraints), machine hour capacity, Overall Equipment Effectiveness (OEE), and bottleneck identification. These metrics provide accurate picture of what a factory can actually produce versus what they claim.

Understanding Design vs. Effective Capacity

Design capacity represents the maximum theoretical output under perfect conditions, while effective capacity accounts for real-world constraints including planned downtime, maintenance, and operational inefficiencies.

The critical performance calculations are:

- Efficiency = (Actual Output ÷ Effective Capacity) × 100%

- Utilization = (Actual Output ÷ Design Capacity) × 100%

These measurements help you understand the gap between what’s theoretically possible and what’s actually achievable in daily operations.

Essential Capacity Metrics

Machine Hour Capacity forms the foundation of capacity assessment. Calculate this as: Number of usable machines × Hours employees can use machines. This determines the productive time available for manufacturing.

Overall Equipment Effectiveness (OEE) combines three critical factors:

- Availability (actual operating time vs. planned operating time)

- Performance (actual production rate vs. ideal production rate)

- Quality (good units produced vs. total units produced)

| Capacity Metric | What It Measures | Industry Benchmark |

|---|---|---|

| OEE Score | Overall equipment effectiveness | 60-85% (world-class) |

| First Pass Yield | Products made correctly first time | 95%+ target |

| MTBF | Mean time between equipment failures | Varies by industry |

| Cpk Index | Process capability vs. specifications | 1.33+ minimum |

Identifying Production Bottlenecks

The bottleneck machine or process determines maximum production rate, as line output cannot exceed what the constraining resource can produce. During your assessment, identify where these bottlenecks occur and how the factory manages them.

Common bottleneck areas in packaging manufacturing include:

- Printing stations with complex color requirements

- Die-cutting operations for custom shapes

- Quality inspection processes

- Packaging and shipping preparation

How Do You Calculate a Factory’s Actual Production Capacity?

Accurate capacity calculation requires systematic analysis of multiple factors that affect real-world production output.

Production capacity calculation follows a structured process: determine machine hour capacity, account for efficiency factors and downtime, then calculate effective production capacity using the formula: (Machine Hours × 60 minutes) ÷ Unit Production Time. This provides realistic expectations rather than theoretical maximums.

Step-by-Step Capacity Calculation

Step 1: Determine Machine Hour Capacity

- Calculate: Number of machines × Operating hours per day × Operating days

- Example: 6 printing machines × 16 hours (two 8-hour shifts) × 230 working days = 22,080 machine hours annually

Step 2: Account for Downtime and Efficiency Factors

- Subtract planned maintenance time (typically 5-10% of total time)

- Factor in changeover times between different products

- Account for quality issues and rework requirements

- Apply efficiency multipliers based on historical performance (usually 70-85%)

Step 3: Calculate Effective Production Capacity

- Effective Capacity = (Machine Hours × 60 minutes) ÷ Unit Production Time

- Example: 22,080 hours × 60 minutes ÷ 24 minutes per unit = 55,200 units annually

Capacity Verification Methods

Professional capacity verification involves multiple calculation approaches to ensure accuracy:

Scheduled Capacity: Based on normal scheduled working hours and standard efficiency rates. This represents typical daily production under normal circumstances.

Maximum Potential Capacity: Uses full 24-hour periods with multiple shifts. This shows absolute maximum output during peak demand periods.

Runtime Capacity: Accounts for all planned downtime, breaks, and maintenance. This provides the most realistic production expectations for planning purposes.

What Documentation Should You Request to Verify Capacity?

Proper documentation provides concrete evidence of manufacturing capabilities and helps identify potential red flags before committing to orders.

Essential documentation includes annual supplier work standards, production process descriptions, equipment specifications, historical production data, and quality certifications. These documents should provide specific metrics, timelines, and performance records rather than general capability statements.

Primary Documentation Requirements

Preliminary Information Package:

- Complete supplier profile including location and contact details

- Detailed part numbers and product descriptions

- Current production volume requirements and projections

- Assessment date and responsible personnel information

Annual Supplier Work Standards:

- Straight time capacity (minimum operating hours and output)

- Normal time capacity (typical operating hours and efficiency)

- Capacity time (maximum temporary hours during peak periods)

- Peak time capacity (absolute maximum emergency production hours)

Process Documentation:

- Detailed production process descriptions with flow charts

- Complete tooling and equipment specifications

- Capital equipment lists with age and condition reports

- Cycle times and historical efficiency rates

Critical Performance Documentation

Production Records and Analysis:

- Daily production logs for the past 6-12 months

- Monthly capacity utilization rates and trends

- Peak production achievements and sustained output records

- Downtime analysis and reasons for production interruptions

Quality Control Documentation:

- Quality management system certifications (ISO 9001, etc.)

- Defect rates and first pass yield statistics

- Customer complaint records and resolution processes

- Quality audit results from third-party inspectors

| Document Category | Specific Requirements | Validation Purpose |

|---|---|---|

| Capacity Reports | Daily/monthly output for 6+ months | Verify consistent performance |

| Equipment Records | Specifications, maintenance logs | Assess reliability and capability |

| Quality Systems | Certifications, defect rates | Confirm quality standards |

| Workforce Data | Staff levels, training records | Evaluate human resource capacity |

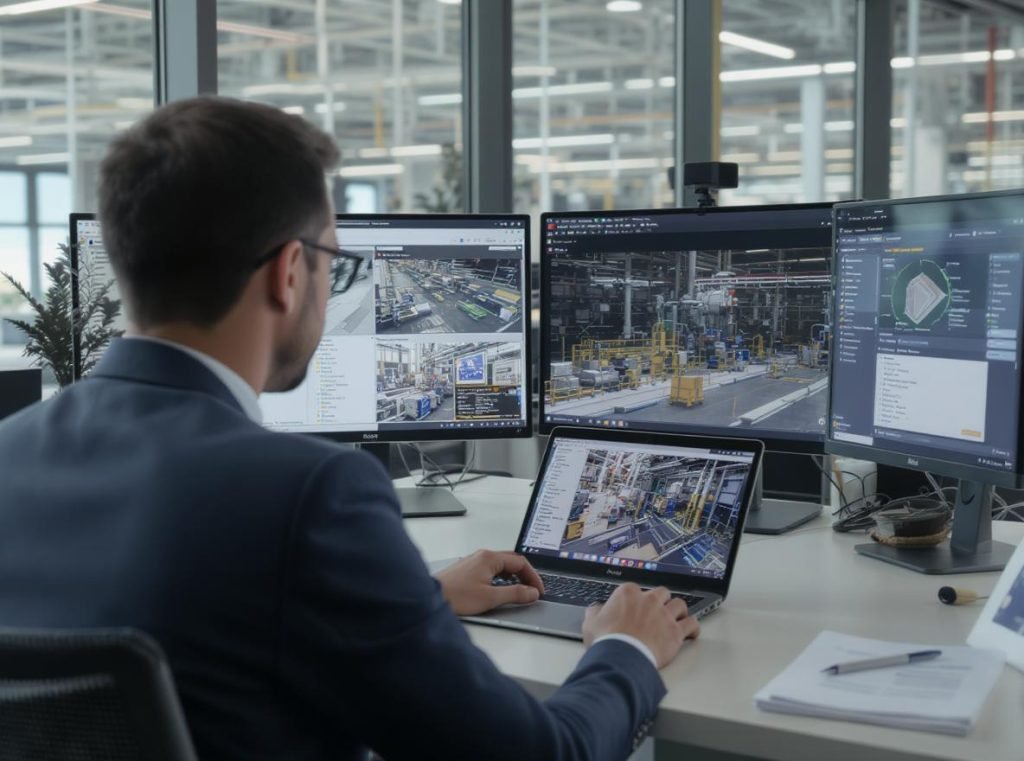

How Can You Assess Production Capacity Remotely?

Remote assessment has become essential for international sourcing, requiring systematic approaches to evaluate capabilities without physical visits.

Remote capacity assessment combines virtual factory tours, comprehensive document review, third-party verification services, and technology-enhanced evaluation tools. Modern digital platforms enable thorough capacity evaluation through video conferencing, real-time monitoring systems, and professional remote audit services.

Virtual Factory Tours and Digital Verification

Comprehensive Virtual Tours should include:

- Live walkthrough of all production areas and equipment

- Real-time demonstration of manufacturing processes

- Close-up views of quality control procedures and testing equipment

- Interviews with production managers and key technical staff

Document-Based Verification Process:

- Cloud-based sharing of production capacity calculations

- Historical production data analysis and trend review

- Quality certifications and third-party audit reports

- Customer references and performance testimonials

Technology-Enhanced Assessment Tools

Digital Monitoring and Analysis:

- Simulation software to model production scenarios and identify constraints

- Data analytics platforms for analyzing historical performance patterns

- Real-time monitoring systems that track production metrics remotely

- Video conferencing tools for detailed technical discussions

Professional Remote Verification Services:

- SGS Remote Factory Quality Assessments provide independent evaluation

- Intertek offers virtual capacity verification with detailed reporting

- Bureau Veritas conducts comprehensive digital factory assessments

- Third-party inspection agencies offer remote audit capabilities

These services provide objective, professional assessment of manufacturing capabilities when physical visits aren’t feasible.

What Red Flags Should You Watch For?

Early identification of warning signs prevents costly production failures and supply chain disruptions.

Critical red flags include frequent unplanned downtime, inaccurate data collection systems, declining supplier performance metrics, excessive lead times, and reluctance to provide detailed documentation. Financial indicators like declining margins and negative cash flow also suggest capacity constraints.

Production and Operational Warning Signs

Equipment-Related Red Flags:

- Frequent unplanned downtime and emergency repairs

- Increasing frequency of “minor” electrical or mechanical issues

- Difficulty diagnosing equipment problems quickly

- High maintenance costs for aging machinery

Process and Data Management Issues:

- Inaccurate data collection or inventory management systems

- Repetitive manual data entry requirements

- Need for frequent system workarounds

- Inconsistent quality control processes

Supply Chain Performance Indicators:

- Declining supplier delivery performance to the factory

- Consistently late factory deliveries to customers

- Unexplained inventory level increases

- Growing late order backlogs

Financial and Management Red Flags

Financial Warning Signs:

- Declining gross profit margins despite stable volumes

- Negative cash flow despite reported profitability

- Inability to pass cost increases to customers

- Reduced investment in capacity expansion or equipment upgrades

Management and Communication Issues:

- Reluctance to share detailed capacity documentation

- Inconsistent information across different communications

- Vague answers about production capabilities

- Unwillingness to provide customer references

| Red Flag Category | Specific Indicators | Potential Impact |

|---|---|---|

| Equipment Issues | Frequent breakdowns, poor maintenance | Production delays, quality problems |

| Data Management | Manual processes, inaccurate records | Planning difficulties, inventory issues |

| Financial Stress | Declining margins, cash flow problems | Capacity investment limitations |

| Communication | Vague responses, inconsistent information | Unreliable partnership potential |

How Do You Validate Claims Through References and Audits?

Third-party validation provides objective assessment of actual manufacturing performance versus claimed capabilities.

Effective validation combines systematic reference checks with professional audit services. Request complete customer lists from the past 3-5 years, conduct structured interviews with current and former clients, and utilize third-party inspection agencies for independent capacity verification.

Strategic Reference Check Protocols

Reference Selection Strategy:

- Request complete customer lists from past 3-5 years (avoid vendor-recommended references)

- Focus on similar-sized organizations in relevant industries

- Seek both current and past clients for comprehensive perspective

- Target companies with similar product complexity and volume requirements

Structured Interview Process:

- Prepare standardized questionnaires for all reference contacts

- Ask open-ended questions about capacity performance and reliability

- Inquire about implementation support and issue resolution processes

- Evaluate long-term relationship sustainability and satisfaction

Critical Reference Questions

Capacity-Specific Inquiries:

- What production volumes did the supplier handle for your projects?

- How effectively did they manage demand fluctuations and seasonal peaks?

- Were delivery commitments consistently met throughout the relationship?

- What capacity constraints or limitations did you encounter?

Performance Validation Questions:

- How responsive was the supplier to capacity increases or rush orders?

- What quality issues arose during high-volume production periods?

- How effectively did they manage production scheduling and communication?

- Would you recommend them for similar capacity requirements?

Professional Audit and Verification Services

Third-Party Inspection Benefits:

- Unbiased assessment from qualified industry experts

- Comprehensive evaluation using standardized criteria and checklists

- Detailed reports with specific recommendations and risk assessments

- Independent verification of equipment, processes, and capabilities

Audit Service Providers:

- SGS offers comprehensive factory capacity assessments

- Intertek provides detailed production capability audits

- Bureau Veritas conducts manufacturing system evaluations

- Local inspection agencies offer region-specific expertise

What Questions Should You Ask During Factory Evaluation?

Systematic questioning reveals crucial information about production capabilities, reliability, and long-term partnership potential.

Essential questions cover current capacity utilization, production planning systems, quality control processes, workforce management, and supply chain integration. Focus on specific metrics and scenarios rather than general capability statements to get accurate assessment data.

Comprehensive Assessment Framework

Facility and Equipment Assessment:

- What is your maximum daily/weekly production capacity for products similar to ours?

- How many production lines are currently operational and dedicated to our product type?

- What is your current equipment utilization rate and efficiency percentage?

- How do you handle preventive maintenance and minimize unplanned downtime?

Production Planning and Scheduling:

- How do you forecast and plan production capacity for different product types?

- What systems do you use for production scheduling and order management?

- How do you prioritize orders and handle rush requests or capacity spikes?

- What is your typical lead time for new orders of various sizes?

Quality and Process Controls:

- What quality control measures are implemented throughout production?

- How do you ensure consistent product quality during high-volume periods?

- What are your current defect rates and first-pass yield percentages?

- How do you handle non-conforming products and rework processes?

Workforce and Management Evaluation

Human Resource Assessment:

- How many employees work directly in production operations?

- What is your workforce turnover rate and employee retention strategy?

- How do you manage shift scheduling, overtime, and capacity flexibility?

- What training programs ensure operational competency and skill development?

Supply Chain Integration:

- How do you manage raw material inventory and supplier relationships?

- What backup plans exist for critical material shortages or disruptions?

- How do you handle supply chain disruptions and maintain production continuity?

- What relationships do you maintain with secondary suppliers?

| Question Category | Key Focus Areas | Information Gained |

|---|---|---|

| Capacity Metrics | Daily output, utilization rates | Actual production capabilities |

| Planning Systems | Forecasting, scheduling tools | Operational sophistication |

| Quality Control | Defect rates, control processes | Quality reliability |

| Workforce | Staff levels, training, retention | Human resource stability |

How Do You Ensure Long-Term Capacity Reliability?

Sustainable manufacturing partnerships require ongoing capacity monitoring, strategic planning, and continuous improvement processes.

Long-term reliability depends on comprehensive demand forecasting, resource allocation planning, risk management strategies, and continuous performance monitoring. Successful partnerships involve regular capacity reviews, flexible production systems, and collaborative improvement initiatives.

Strategic Capacity Planning

Demand Forecasting and Analysis:

- Analyze historical demand patterns and identify seasonal trends

- Incorporate market research insights and customer growth projections

- Consider technological developments and industry changes

- Plan for multiple demand scenarios including best-case and worst-case situations

Resource Allocation Planning:

- Evaluate equipment lifecycle and replacement schedules

- Assess workforce development and training requirements

- Plan facility expansions or modifications based on growth projections

- Consider strategic decisions about outsourcing versus internal capacity expansion

Risk Management and Mitigation

Comprehensive Risk Assessment:

- Supply chain disruptions and supplier reliability issues

- Equipment failures and maintenance requirements

- Workforce availability and skill gaps

- Market demand variability and economic factors

Mitigation Strategies Implementation:

- Develop redundant capacity and backup supplier relationships

- Implement comprehensive preventive maintenance programs

- Create cross-training initiatives and workforce development programs

- Establish flexible production systems that can adapt to changing demands

Continuous Monitoring and Improvement

Performance Monitoring Systems:

- Track key performance indicators continuously using dashboard systems

- Monitor capacity utilization trends and efficiency improvements

- Assess quality metrics and customer satisfaction scores

- Evaluate supply chain performance and supplier reliability

Continuous Improvement Processes:

- Implement regular capacity reviews and planning updates

- Conduct periodic risk assessments and mitigation strategy reviews

- Invest in technology upgrades and process improvements

- Maintain active supplier relationship management programs

Summary

Assessing factory production capacity requires systematic evaluation of design versus effective capacity, comprehensive documentation review, and validation through references and audits. Key success factors include understanding bottlenecks, calculating realistic production capabilities, and implementing continuous monitoring systems. Professional third-party verification services provide objective assessment when remote evaluation is necessary.

Ready to find a reliable manufacturing partner for your custom packaging needs? Contact Acreet today for expert consultation on factory capacity assessment and supplier selection. Our experienced team helps you evaluate production capabilities, ensure quality standards, and build sustainable manufacturing partnerships that support your business growth.