Imagine your customer struggling with a flimsy food box that tears apart halfway to their destination, spilling contents everywhere. Poor carry design doesn’t just frustrate consumers – it damages your brand reputation and creates negative experiences that customers remember.

The key to designing easy-to-carry food boxes lies in three fundamental elements: ergonomic handle placement, balanced weight distribution, and structural integrity. By incorporating proper grip zones, using appropriate materials, and considering human hand anatomy, you can create packaging that enhances the customer experience while protecting your food products during transport.

Let’s explore the specific design strategies that will transform your food packaging from a carrying challenge into a customer delight.

Table of Contents

ToggleWhat Makes a Food Box Easy to Carry?

Understanding consumer needs is crucial for any food packaging design. When customers order takeout or purchase ready-to-eat meals, they expect packaging that won’t fail them during transport.

Easy-to-carry food boxes feature three essential characteristics: comfortable grip points that accommodate natural hand positioning, sturdy construction that maintains structural integrity under load, and balanced design that prevents awkward tilting or shifting during transport.

The foundation of carry-friendly design starts with understanding human ergonomics. Our hands naturally form specific grip patterns, and successful food box design works with these natural tendencies rather than against them. Weight distribution plays an equally important role – a well-balanced box feels lighter and more secure in the consumer’s hands.

Modern consumers also value convenience features that enhance their experience:

- Handle positioning: Placed at optimal heights for natural arm movement

- Grip comfort: Smooth edges that don’t cut into fingers during extended carrying

- Load capacity: Adequate strength to handle the intended food weight without deformation

Consider the difference between carrying a traditional pizza box versus a well-designed handled food container. The pizza box requires an awkward flat-palm grip that becomes uncomfortable quickly, while a properly designed food box with integrated handles allows for a natural, comfortable carrying position.

How Do Handle Designs Impact Consumer Experience?

Handle design directly affects how consumers interact with your food packaging. The wrong handle can turn a pleasant dining experience into a frustrating ordeal.

Effective handle designs consider grip width, material choice, and positioning to create comfortable carrying experiences. Handles should be wide enough to distribute pressure across fingers, positioned for natural arm positioning, and made from materials that provide secure grip without causing discomfort.

The most successful handle designs incorporate several key principles. First, they distribute weight evenly across the hand to prevent pressure points that cause discomfort. Second, they position handles at heights that allow arms to hang naturally, reducing strain on shoulders and wrists.

Material selection for handles requires careful consideration:

| Handle Material | Advantages | Best Use Cases |

|---|---|---|

| Integrated Cardboard | Cost-effective, recyclable | Light to medium weight foods |

| Rope/String | Flexible, comfortable grip | Heavier items, bulk orders |

| Die-cut Openings | No additional materials needed | Single-serve portions |

Professional packaging designers recommend testing handle comfort with actual users carrying loaded boxes for realistic distances. What feels comfortable for 30 seconds may become painful during a 10-minute walk home.

Smart handle placement also considers how consumers naturally balance loads. Centered handles work well for balanced contents, while offset handles may be better for boxes with uneven weight distribution.

What Role Does Box Shape Play in Portability?

Box shape significantly influences how easily consumers can carry and maneuver your food packaging. The wrong proportions can make even lightweight contents feel cumbersome.

Optimal food box shapes balance internal volume efficiency with external handling convenience. Rectangular boxes with moderate height-to-width ratios provide stable carrying characteristics, while excessively tall or wide designs create awkward handling situations that increase drop risk.

Traditional square boxes offer stability but can be challenging to grip securely. Rectangular designs with slight elongation often provide better grip points and more natural carrying positions. The golden ratio of approximately 1.6:1 length to width creates visually appealing proportions that also handle well.

Height considerations are equally important for portability:

- Low profile boxes: Easy to balance but may require larger footprints

- Medium height boxes: Best compromise between capacity and handling

- Tall boxes: Higher capacity but increased tipping risk

Shape also affects how boxes stack and nest during transport. Consumers often carry multiple containers, and designs that stack securely reduce the risk of spills and make transportation more manageable.

Consider how your box shape affects the consumer’s other activities. Can they easily open doors while carrying the box? Does the shape allow them to see where they’re walking? These practical considerations separate good design from great design.

How Important is Material Selection for Carrying Comfort?

Material choice directly impacts both the structural integrity and carrying comfort of food packaging. The wrong material can lead to box failure, burns, or uncomfortable handling experiences.

Material selection for carry-friendly food boxes requires balancing strength, insulation properties, and grip characteristics. Corrugated cardboard provides excellent strength-to-weight ratios, while specialized coatings can enhance grip and moisture resistance without compromising recyclability.

Different food types require different material considerations. Hot foods need materials that provide thermal protection for consumers’ hands, while cold foods may require moisture-resistant properties to prevent box degradation.

Key material properties for carrying comfort include:

- Thermal insulation: Prevents burns from hot contents

- Surface texture: Provides secure grip without being abrasive

- Structural strength: Maintains integrity under normal carrying loads

- Moisture resistance: Prevents weakening from condensation or spills

Weight is another crucial factor in material selection. While stronger materials provide better protection, they also add weight that consumers must carry. The optimal balance depends on your specific food products and target carrying distances.

Advanced material options continue expanding. Recycled materials with enhanced strength properties allow for environmentally responsible packaging that doesn’t compromise carrying performance.

What Are the Best Handle Types for Different Food Containers?

Different food types and container sizes require specific handle approaches to optimize the carrying experience. Understanding these requirements helps you choose the most effective solution for your products.

Handle type selection depends on container weight, size, and intended use duration. Die-cut handles work well for lighter foods, integrated rope handles suit heavier items, and fold-out handles provide good compromise solutions for medium-weight containers.

Let’s examine the most effective handle types for various applications:

Die-Cut Handles

These handles are cut directly from the box material, creating openings for finger grip. They work excellently for lighter food containers and provide cost-effective solutions without additional materials.

Integrated Rope Handles

Rope or cord handles attach through reinforced holes, distributing weight across a wider grip area. These handles excel with heavier food orders and provide comfortable extended carrying.

Fold-Out Cardboard Handles

These handles fold out from the box sides when needed, staying flat during storage and shipping. They offer good carrying comfort while maintaining compact packaging profiles.

Specialized handle designs address specific food packaging challenges:

| Food Type | Recommended Handle | Key Benefits |

|---|---|---|

| Pizza Boxes | Side finger holes | Maintains flat carrying position |

| Soup Containers | Integrated loops | Heat protection, secure grip |

| Multi-item Orders | Central rope handle | Balanced weight distribution |

| Single Portions | Die-cut openings | Cost-effective, simple design |

Professional food service operations often require handles that work with gloves, adding another design consideration for your target market.

How Do You Balance Functionality with Cost Efficiency?

Creating easy-to-carry food boxes requires balancing enhanced functionality with reasonable production costs. Smart design decisions can achieve both objectives without compromise.

Cost-efficient carry-friendly design focuses on strategic material use, simplified manufacturing processes, and multi-functional design elements. By integrating handles into the box structure rather than adding separate components, you can enhance functionality while controlling costs.

The most cost-effective approaches leverage existing manufacturing capabilities. Die-cut handles use the same cutting processes as box formation, adding minimal production complexity. Strategic perforation patterns can create easy-opening features without additional materials or processes.

Consider these cost-optimization strategies:

- Material efficiency: Design handles that use waste material from cutting processes

- Process integration: Combine handle formation with existing manufacturing steps

- Volume scaling: Handle designs that become more cost-effective with larger production runs

- Multi-functionality: Design elements that serve both structural and carrying purposes

Value engineering approaches help identify the most impactful design elements. Sometimes simple improvements like reinforced grip areas provide significant carrying improvements with minimal cost increases.

Remember that improved carrying experience can justify modest cost increases through enhanced customer satisfaction and brand differentiation. Customers often associate packaging quality with food quality, making carry-friendly design a valuable investment.

What Safety Considerations Should Guide Food Box Design?

Safety considerations are paramount in food box design, especially when creating features that encourage consumer handling and transport.

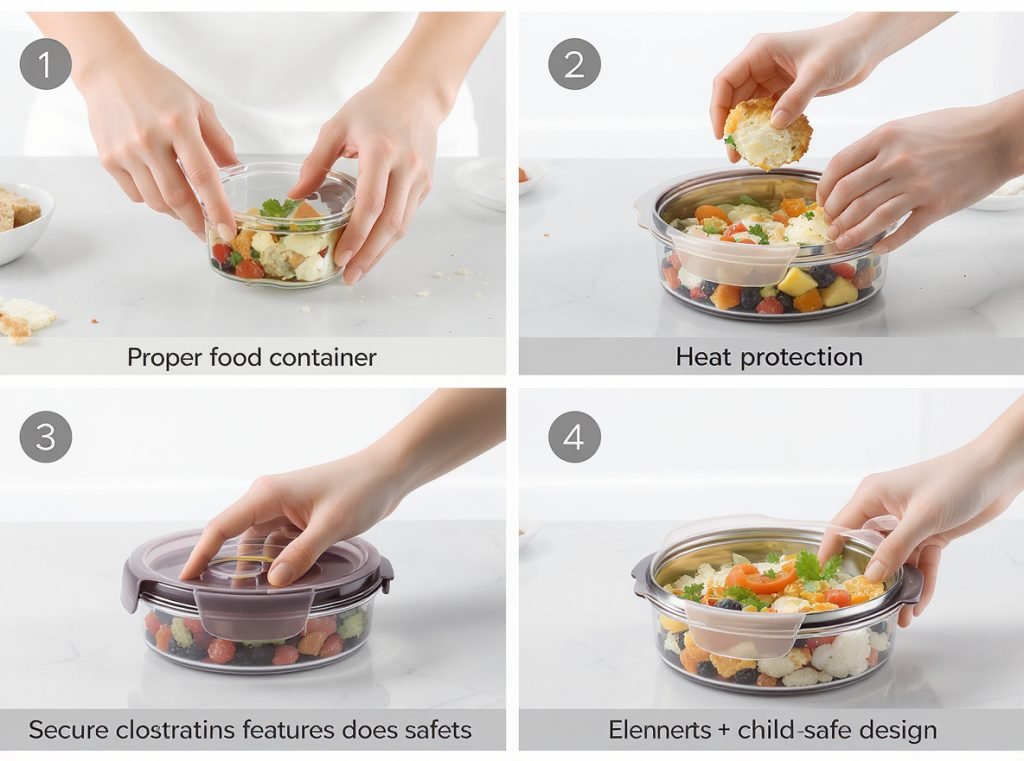

Safe food box design addresses thermal protection, structural integrity under load, and secure closure systems. Consumers should be able to carry containers safely without risk of burns, spills, or box failure that could cause injury or property damage.

Thermal safety represents a critical consideration for hot food containers. Handle placement must account for heat transfer, ensuring consumers can grip boxes safely even when contents are at serving temperature. Strategic ventilation can help manage internal temperatures while maintaining food quality.

Load safety requires understanding the maximum weights consumers will reasonably carry. Box design should maintain structural integrity at 150% of normal loading to account for handling variations and transport stresses.

Safety features to incorporate include:

- Heat shields: Insulating layers between hot contents and grip points

- Load indicators: Visual cues about maximum safe carrying weights

- Secure closures: Latching systems that prevent accidental opening during transport

- Edge protection: Rounded corners and smooth edges that prevent cuts

Child safety considerations become important for family-oriented restaurants. Handles and closures should be designed to prevent small children from accessing contents unsupervised while remaining easy for adults to operate.

Emergency situations also require consideration. Can consumers quickly release or abandon the package if necessary? Design should never trap hands or fingers in carrying positions.

How Can You Test Your Food Box Design Effectiveness?

Testing food box designs with real consumers provides invaluable insights that can’t be replicated through theoretical analysis alone.

Effective food box testing involves real users carrying actual food loads over realistic distances while monitoring comfort, security, and functionality. Testing should include diverse user groups, various food types, and different carrying scenarios to ensure broad applicability.

Comprehensive testing protocols evaluate multiple performance aspects. Structural testing verifies that boxes maintain integrity under normal and stress conditions. Ergonomic testing assesses carrying comfort over time and distance. User experience testing identifies practical issues that emerge during real-world use.

Key testing scenarios include:

- Short distance carrying: Restaurant to car transport

- Extended carrying: Walking several blocks with food

- Multi-box carrying: Handling multiple containers simultaneously

- Weather conditions: Performance in rain, wind, or extreme temperatures

User feedback collection methods range from structured surveys to observational studies. Watch for unconscious behaviors like hand repositioning, box tilting, or grip adjustments that indicate design problems.

Digital testing tools can supplement physical testing. Computer modeling can predict stress points and identify potential failure modes before physical prototyping. However, nothing replaces real-world testing with actual consumers and food products.

Iterative testing approaches work best, with each design revision addressing issues identified in previous testing rounds. This process continues until user feedback consistently indicates satisfactory carrying experiences.

What Future Trends Will Shape Food Box Carrying Design?

The food packaging industry continues evolving, driven by consumer preferences, environmental concerns, and technological advances that will shape future carrying design approaches.

Future food box designs will integrate smart materials, sustainable production methods, and enhanced user interfaces. Trends include temperature-responsive materials, integrated tracking systems, and modular designs that adapt to different food types while maintaining optimal carrying characteristics.

Sustainability drives many current innovations. Biodegradable materials with enhanced strength properties allow for environmentally responsible packaging without compromising carrying performance. New manufacturing processes reduce material waste while creating more sophisticated handle and grip designs.

Fiber-based packaging innovations will provide sustainable alternatives to plastic containers while maintaining durability and functionality through technological advancement. The e-commerce growth will continue driving demand for protective, sustainable solutions that withstand shipping conditions while minimizing environmental impact and reinforcing brand identity.

Technology integration opens additional possibilities:

- Smart handles: Sensors that monitor temperature and provide carrying guidance

- QR integration: Information systems built into handle areas for enhanced consumer engagement

- Modular systems: Standardized handles that work across multiple container types

- AI-powered personalization: Packaging that adapts messaging based on consumer preferences

Consumer behavior changes also influence design directions. Increased food delivery creates demand for packaging optimized for courier handling rather than consumer carrying. Multi-modal transport (walking, cycling, public transit) requires more versatile carrying solutions.

Global market expansion introduces new cultural considerations for handle design and carrying preferences. What works in one market may not translate directly to different cultural contexts and consumer expectations.

Summary

Creating easy-to-carry food boxes requires careful attention to ergonomics, materials, and user experience. Success comes from understanding how consumers naturally hold and transport containers, then designing features that work with these behaviors rather than against them. The best designs balance functionality, cost efficiency, and safety while anticipating future trends in food packaging and consumer preferences.

Ready to transform your food packaging with carry-friendly designs that delight customers? At Acreet, we specialize in creating custom food boxes that combine innovative carrying solutions with cost-effective manufacturing. Our experienced design team can help you develop packaging that enhances your brand while improving the customer experience. Contact us today to discuss your custom food packaging needs and discover how better design can boost your business success.