Picture this: your customer finally receives their long-awaited order, excitement builds as they hold your beautifully designed package, but then frustration sets in as they struggle to open it. Market research reveals that over 70% of consumer decisions occur at the point of purchase, making packaging your first and most important brand touchpoint.

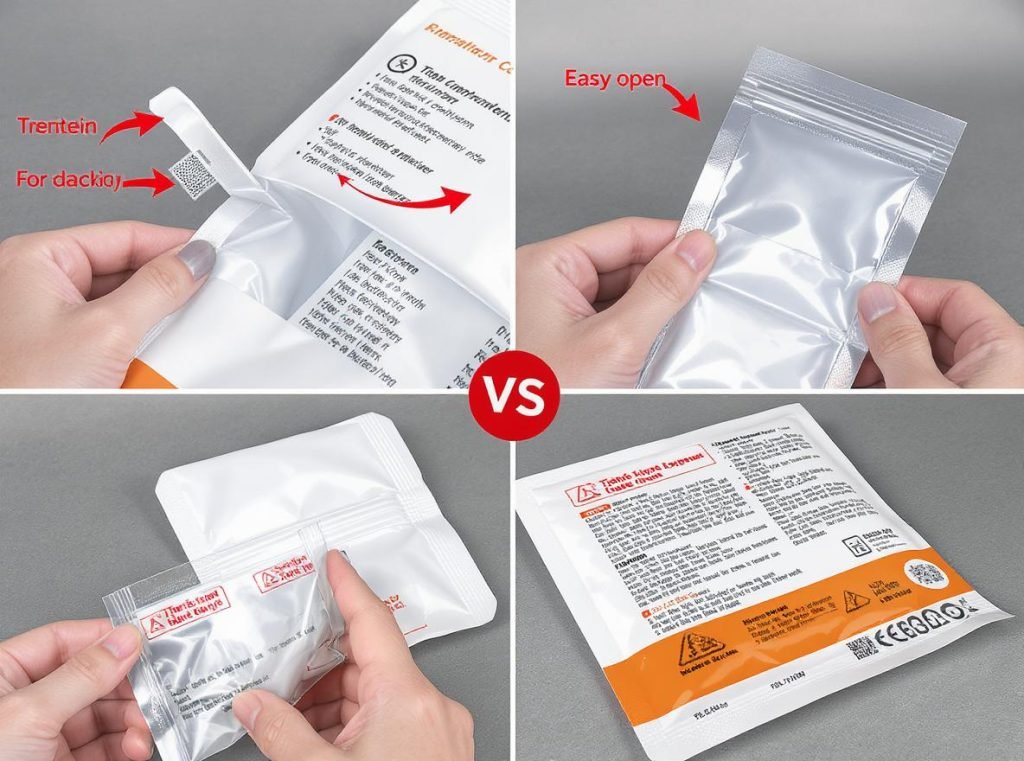

Easy-open packaging design incorporates specific features like tear strips, pull tabs, and strategic perforations that allow customers to access products quickly without tools or excessive force. The key is balancing security, protection, and accessibility while maintaining your brand’s visual appeal and meeting the needs of diverse user groups.

Ready to discover how smart packaging design can transform your customer experience and expand your market reach? Let’s explore the essential elements that make packaging both beautiful and universally accessible.

Table of Contents

ToggleWhy Is Easy-Open Packaging Design So Important for Your Brand?

Easy-open packaging isn’t just a convenience feature—it’s a critical component of your customer experience strategy that directly impacts brand perception and market reach. When customers can effortlessly access your products, it creates positive first impressions that drive loyalty and repeat purchases.

Easy-open packaging design directly impacts customer satisfaction, reduces return rates, and enhances brand loyalty by eliminating the frustration barrier between customers and your products. Studies show that consumers actively avoid buying products with difficult-to-open packaging, making accessibility a crucial business consideration.

The business impact extends far beyond convenience. Research indicates that nearly half of people over 65 find it difficult to open everyday items like plastic bottles and jars, while parents with young children need packaging that’s accessible to adults but safe for children. With an aging population and increasing awareness of accessibility needs, brands that prioritize easy-open features can tap into broader market segments.

Consumer perception studies show that 68% of customers believe packaging reflects brand values. When consumers can independently access and use products, they’re more likely to develop positive associations with your brand and make repeat purchases. This demographic includes seniors, parents with young children, and individuals with disabilities who may face challenges with traditional packaging designs.

From a manufacturing perspective, incorporating easy-open features during the design phase is far more cost-effective than retrofitting existing packaging. At Acreet, we’ve seen how thoughtful packaging design can transform customer relationships and drive business growth while reducing customer service inquiries about opening instructions.

What Are the Most Effective Easy-Open Features for Custom Packaging?

Understanding the various easy-open mechanisms helps you choose the right solution for your specific product and customer needs. Each feature serves different purposes and works better with certain packaging materials and product types.

The most effective easy-open features include tear strips, pull tabs, laser-scored perforations, and resealable systems—each designed to provide effortless access while maintaining package integrity during shipping and storage.

Tear Strips and Advanced Perforation Technologies

Tear strips represent one of the most reliable easy-open solutions, offering controlled opening paths that eliminate the need for scissors or knives. These features can be integrated directly into packaging tape or materials, providing a consistent opening experience across different product types.

Modern perforation technologies have evolved significantly, with laser scoring now enabling precise control over tear patterns. Advanced perforation designs like the “Reverse Cut” method create seamless opening experiences while maintaining packaging integrity during transport. These technologies allow for customizable opening forces and can be tailored to specific product requirements.

Key advantages of tear strips include:

- Controlled opening paths that prevent random tearing

- Consistent force requirements across production runs

- Integration with existing packaging materials

- Clear visual indicators for opening location

Pull Tabs and Grip Enhancement Features

Pull tabs and grip areas provide intuitive opening mechanisms that require minimal instruction. Large grip areas are particularly important for users with limited dexterity, as they offer better control and require less precise hand positioning. The key is ensuring these features are prominently positioned and easy to identify.

Effective pull tab design considerations:

- Minimum tab width of 15mm for comfortable gripping

- High-contrast colors for easy identification

- Textured surfaces for improved grip

- Strategic placement aligned with natural hand positions

Resealable and Multi-Access Solutions

Zip closures and resealable systems offer added convenience by allowing packages to be opened and closed multiple times. This feature is particularly valuable for products consumed over multiple occasions, maintaining freshness while providing easy access.

| Feature Type | Best Applications | Opening Force | Reusability |

|---|---|---|---|

| Tear Strips | Single-use products | 3-5 lbs | One-time |

| Pull Tabs | Light to medium products | 2-4 lbs | One-time |

| Zip Closures | Multi-use products | 1-3 lbs | Multiple |

| Spout Designs | Liquid products | 2-4 lbs | Multiple |

Spout designs enable precision pouring for liquid contents while maintaining the ability to reseal. These features are especially important for products like beverages or liquid food items where controlled dispensing is crucial.

How Do You Choose the Right Easy-Open Method for Your Product?

Selecting the appropriate easy-open mechanism depends on multiple factors including your product type, target audience, shipping requirements, and regulatory compliance. Making the right choice ensures optimal functionality without compromising protection or aesthetics.

Choose your easy-open method based on product characteristics, demographic considerations, shelf life requirements, and consumer usage patterns—balancing accessibility with protection requirements while meeting relevant standards.

Product-Specific Considerations

Product characteristics fundamentally determine the boundaries for packaging type and opening method selection. Liquid products require different considerations than solid items, and fragile products need protective features that don’t compromise accessibility.

Weight and size significantly influence mechanism selection. Products over two pounds require more robust easy-open mechanisms, while lighter items can use simpler solutions. Long, narrow packages benefit from longitudinal tear strips, while square or rectangular packages often work better with corner-mounted pull tabs.

Shelf life and storage requirements play crucial roles in determining appropriate opening mechanisms. Products requiring long-term storage may need stronger seals that could conflict with easy-open features, requiring careful balance between protection and accessibility.

Target Demographic Analysis

Age-related considerations are paramount when selecting opening methods. Packaging systems with torque closures, while familiar, often present challenges for elderly consumers due to reduced grip strength. Twist-off caps with small diameters can be particularly problematic despite requiring lower opening forces.

Consider creating customer personas that include physical considerations:

- Seniors (65+): Require larger grip areas and forces under 5 pounds

- Parents with children: Need quick access but child-resistant features

- Individuals with disabilities: Benefit from multiple opening options

- General consumers: Expect intuitive, tool-free opening

Cultural and regional preferences may influence opening method effectiveness. What works in one market may not translate effectively to another, requiring localized testing and adaptation.

Usage Pattern Matching

Consumer usage patterns should inform opening method selection. Products consumed in single servings may prioritize simple, one-time opening, while multi-use items need robust resealable systems.

Consider the complete user journey from purchase to disposal. Packaging that creates problems at different stages of use can negate even well-designed opening features.

What Materials Work Best for Easy-Open Packaging Design?

Material selection significantly impacts the effectiveness of your easy-open features. Different materials respond differently to perforation, scoring, and tear mechanisms, requiring tailored approaches for optimal results.

Corrugated cardboard, kraft paper, and specialized flexible films offer the best combination of easy-open functionality and structural integrity, while hybrid solutions can optimize both protection and accessibility.

Corrugated Cardboard Excellence

Corrugated cardboard remains the gold standard for easy-open packaging design. Its layered structure allows for precise perforation control, and the material tears cleanly along predetermined lines. The fluting direction affects tear characteristics—tears parallel to the fluting are easier than perpendicular tears.

Single-wall corrugated works well for lighter products and offers excellent tear control with predictable opening patterns. Double-wall provides more strength but requires deeper perforations for effective opening. When designing for corrugated, consider the grain direction and plan your easy-open features accordingly.

Corrugated materials are lightweight, cost-effective, and offer excellent printing capabilities for branding while providing the structural integrity needed for shipping protection.

Flexible Films and Advanced Materials

Polyethylene (PE) and polypropylene (PP) films offer excellent flexibility and can be engineered for controlled tearing. These materials can be designed with specific tear propagation characteristics, allowing for predictable opening patterns that don’t require excessive force.

Multilayer flexible structures can combine barrier properties with easy-open functionality. The key is balancing protective qualities with materials that tear cleanly and consistently. Specialized sealant films can provide necessary barrier properties while enabling easy peeling actions.

Sustainable and Hybrid Solutions

Kraft paper and paperboard provide sustainable options that can be easily perforated or scored for opening. These materials are particularly suitable for products where environmental considerations are important to your brand positioning.

Combining materials can optimize both protection and accessibility. For example, a cardboard structure with strategic flexible film elements can provide the best of both worlds. Laminated structures allow for precise control over opening characteristics while maintaining necessary barrier properties.

How Can You Test Your Easy-Open Packaging Design Before Production?

Testing is crucial for ensuring your easy-open features work reliably across different user groups and conditions. Comprehensive testing prevents costly redesigns and customer complaints after launch.

Effective testing involves quantitative force measurement, consumer panel testing with diverse demographics, durability testing under shipping conditions, and standards compliance verification for optimal performance.

Quantitative Testing Methods

Mechanical testing provides objective data about opening forces and package performance. Standard tests measure peel strength, tear resistance, and torque requirements, offering quantifiable benchmarks for design optimization.

Force measurement systems can evaluate the specific forces required for different opening actions. Industry standards suggest maximum opening forces between 3-8 pounds for most consumer products, with lower forces preferred for elderly or disabled users.

Key measurements include:

- Tear initiation force (force to start opening)

- Tear propagation force (force to continue opening)

- Consistency across production samples

- Performance under various environmental conditions

Consumer Panel Testing

Consumer panel testing following standards like CEN TS 15945 provides valuable insights into opening effectiveness. These tests typically involve 100 consumers aged 65-80, with 70% being female to reflect natural grip strength variations.

Focus group studies provide qualitative insights into consumer perceptions and experiences. These sessions can reveal disconnect between measured forces and perceived difficulty, highlighting the importance of design factors beyond pure mechanics.

Testing should include:

- First-time users without instructions

- Users with limited dexterity

- Opening in different environments (bright/dim lighting, sitting/standing)

- Repeated opening for resealable designs

- Cultural and regional preference variations

Durability and Standards Compliance

Durability testing ensures that easy-open features maintain their functionality throughout the product lifecycle. This includes testing under various environmental conditions and handling scenarios that simulate real-world distribution.

ISO 17480:2015 provides comprehensive guidelines for accessible packaging design with focus on ease of opening. This standard covers opening location, methods, and evaluation techniques. CEN TS 15945 offers specific testing methods for evaluating packaging ease of opening.

Create a testing matrix that includes temperature ranges (-10°F to 140°F), humidity levels (10% to 90%), compression forces, impact scenarios, and vibration frequencies to simulate transport conditions.

What Are Common Mistakes to Avoid in Easy-Open Packaging Design?

Learning from common pitfalls helps you create more effective designs while avoiding costly mistakes. Understanding these issues early in the design process saves time, money, and customer satisfaction.

The most frequent mistakes include prioritizing aesthetics over functionality, inadequate testing with target demographics, poor opening indicators, and failing to consider diverse user needs during the design phase.

Design and Functionality Errors

Prioritizing aesthetics over functionality represents one of the most common packaging failures. While visual appeal is important, packaging that looks great but frustrates users ultimately damages brand perception and reduces repeat purchases.

Inadequate opening indicators lead to user confusion and frustration. Packaging should provide clear, intuitive signals about where and how to open. False affordances—design elements that suggest one opening method but require another—create particularly negative user experiences.

The biggest structural mistake is weakening the package too much in pursuit of easy opening. Overly aggressive perforations can cause premature failure during shipping, while poorly placed tear strips might create stress concentration points.

Material and Manufacturing Issues

Choosing inappropriate materials for the intended opening method can lead to unpredictable tearing or excessive force requirements. Materials must be selected based on their specific performance characteristics for the chosen opening mechanism.

Inadequate quality control during production can result in inconsistent opening performance. Even well-designed features can fail if manufacturing tolerances aren’t properly maintained. Variations in perforation depth or placement can make some packages easy to open while others remain difficult.

User Experience Failures

Overlooking diverse user needs results in packaging that works for some but excludes others. Inclusive design principles should be applied from the beginning of the design process, considering users with varying abilities and preferences.

Common oversights include:

- Designing only for average grip strength

- Ignoring visual impairment considerations

- Failing to test with elderly users

- Not considering cultural opening preferences

- Inadequate instruction design

Poor instruction design can negate even well-designed opening features. Instructions should be clear, concise, and accessible to users with varying literacy levels and visual capabilities.

How Do You Balance Security and Easy-Open Features?

Protecting your product during shipping while maintaining easy access for customers requires careful engineering. The challenge lies in creating packaging that’s tough enough to survive distribution but simple enough for customers to open effortlessly.

Effective security balancing uses tamper-evident features, child-resistant mechanisms where required, and layered security approaches that provide comprehensive protection without compromising accessibility for legitimate users.

Tamper-Evident Integration

Tamper-evident packaging can be designed to provide both security and accessibility. Modern tamper-evident features like breakable caps, shrink bands, and tear strips can be engineered to require minimal force while still providing clear evidence of tampering.

Layered security approaches combine multiple tamper-evident features to create comprehensive protection without compromising accessibility. This might include both primary tamper-evident seals and secondary security features that work together.

Effective tamper-evident solutions include:

- Breakaway seals that activate during normal opening

- Perforated bands that tear when accessed

- Color-changing indicators for visual confirmation

- Irreversible opening mechanisms that show tampering

Child-Resistant Design Balance

Child-resistant packaging presents unique challenges when combined with easy-open requirements. The packaging must be difficult for children to open while remaining accessible to adults, including those with limited strength or dexterity.

Sequential opening mechanisms can provide child resistance while maintaining adult accessibility. These designs require specific sequences of actions that are challenging for children but manageable for adults with proper instruction.

The key is creating packaging that requires cognitive understanding rather than just physical strength, making it accessible to adults while remaining challenging for children under five years old.

Regulatory Compliance

FDA requirements for tamper-evident packaging must be balanced with accessibility needs. The packaging must provide “visible evidence to consumers that tampering has occurred” while remaining user-friendly.

Industry-specific regulations may impose additional requirements that affect easy-open design. Pharmaceutical, food, and other regulated industries have specific standards that must be met without compromising accessibility.

International standards like ISO 17480:2015 provide frameworks for balancing security and accessibility, ensuring that easy-open features don’t compromise necessary safety requirements.

Summary

Easy-open packaging design represents a fundamental shift toward customer-centric product interaction that directly impacts brand perception and market reach. By incorporating scientifically-tested features like laser-scored perforations, optimized pull tabs, and intuitive opening mechanisms, you can create packaging that delights customers while maintaining product protection and security.

Success requires understanding your diverse customer base, selecting appropriate materials and mechanisms, conducting thorough testing with representative user groups, and balancing accessibility with necessary security features. Remember that inclusive design principles benefit all users, not just those with specific needs.

Ready to transform your packaging into a competitive advantage that expands your market reach? Contact Acreet today to discuss how our expert packaging design team can help you create custom solutions that combine protection, functionality, and universal accessibility. Let’s work together to make your products accessible to everyone—send us your inquiry and discover what’s possible with thoughtful, research-backed packaging design.