Placing multiple orders from Chinese manufacturers can feel like gambling with your brand reputation. One batch arrives perfect, the next disappoints customers. This quality rollercoaster costs you money, damages relationships, and keeps you awake at night wondering what went wrong.

The key to consistent quality across multiple orders from China lies in establishing comprehensive quality control systems, implementing AQL sampling standards, conducting regular supplier audits, and building long-term partnerships. Success requires combining systematic processes, digital technology, and collaborative relationships with reliable suppliers.

Let’s explore the proven strategies that successful businesses use to maintain consistency across all their packaging orders from China.

Table of Contents

ToggleWhat Are the Main Challenges in Maintaining Quality Consistency?

Managing quality across multiple orders from Chinese manufacturers presents unique obstacles that can significantly impact your brand reputation and customer satisfaction.

The primary challenges include cultural and linguistic barriers, lack of standardization across factories, material sourcing variations, cost-cutting pressures, and the expansive diversity of China’s manufacturing base. These factors create quality inconsistencies that require strategic management.

Cultural and Communication Barriers

Language barriers often lead to misunderstandings about specifications, while cultural differences in business practices affect quality expectations. Chinese manufacturers may prioritize speed over perfection, while Western businesses emphasize consistency. This fundamental difference requires careful alignment of expectations.

The expansive and diverse manufacturing base means companies struggle with maintaining uniform quality standards across multiple production facilities, which can vary significantly in their practices and capabilities.

Lack of Standardization

Quality standards can vary dramatically from one factory to another, sometimes even within the same industry. This variance results in stark differences in product reliability and durability between orders.

Some manufacturers attempt to reduce expenses by compromising on essential quality control measures, while others may create counterfeit products that closely imitate well-known brands, tarnishing legitimate businesses’ reputations.

| Challenge | Impact Level | Primary Solution |

|---|---|---|

| Communication barriers | High | Clear specifications and visual references |

| Factory standardization | Critical | Supplier audits and certifications |

| Material consistency | Medium | Approved vendor lists and batch tracking |

| Cost-cutting pressure | High | Long-term partnerships and value emphasis |

Production Variables

Different production shifts, equipment maintenance schedules, and operator skill levels all impact quality. New employees might not understand your specific requirements as well as experienced workers, while machine calibration can drift over time, gradually affecting product dimensions or print quality.

How Do You Establish Clear Quality Standards?

Quality standards serve as the foundation for consistent manufacturing outcomes and must be clearly communicated to eliminate interpretation gaps.

Quality standards are clear, measurable requirements that ensure products, services, and processes fulfill desired specifications. Defining clear and concise quality standards is the first element of effective supplier quality management, providing uniform criteria for reliability that suppliers worldwide can follow.

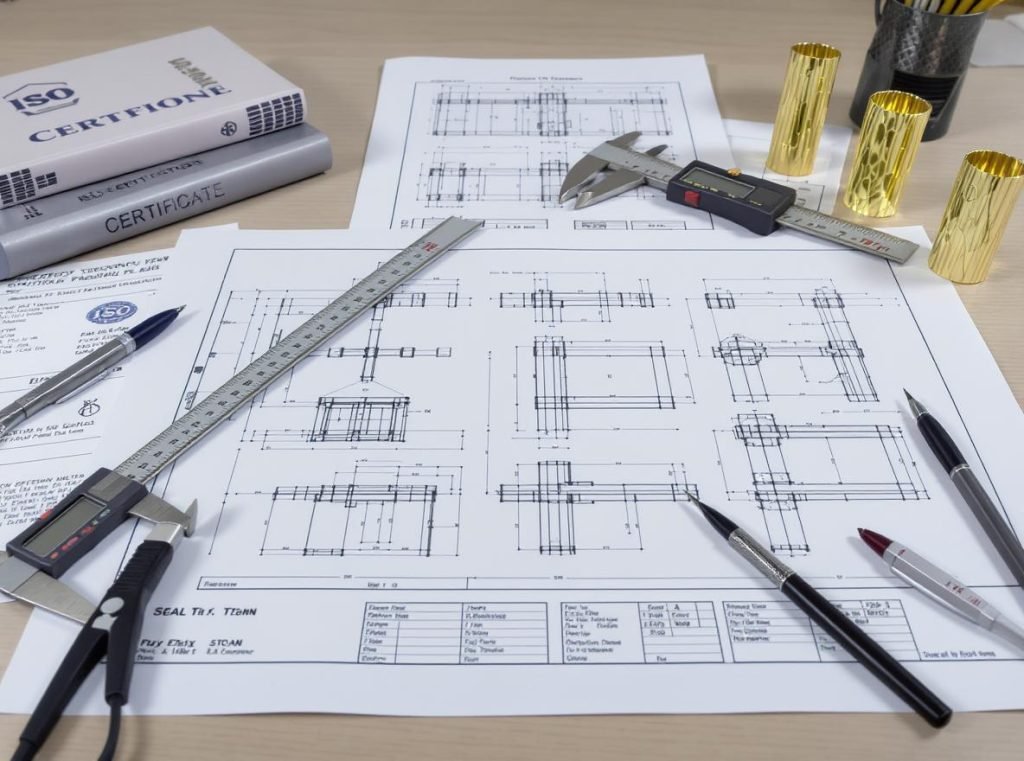

International Standards Implementation

Implement internationally recognized standards such as ISO 9001, which focuses on continuous improvement and customer satisfaction. If you’re looking for a Chinese supplier that can produce high-quality products, checking for ISO 9001 certification is essential.

Key certification standards to verify include:

- ISO 9001: Quality management systems

- ISO 14001: Environmental management systems

- Industry-specific certifications: Such as IATF 16949 for automotive or ISO 13485 for medical devices

Detailed Technical Specifications

Create comprehensive specification documents covering every aspect of your packaging, including dimensions, materials, printing specifications, and performance requirements. Don’t assume anything is obvious – specify color codes, paper thickness, folding requirements, and finish details.

Visual Reference Standards

Provide physical samples or high-quality photos showing acceptable and unacceptable quality levels. Visual references eliminate language barriers and provide clear quality benchmarks that transcend cultural differences.

Create “golden samples” representing perfect quality, document common defects with photos, establish clear pass/fail criteria, and update references when specifications change.

What Quality Control Systems Should You Implement?

Effective quality control requires systematic approaches with multiple checkpoints throughout the production process to catch issues before they become costly problems.

Quality control in China refers to proactive measures taken by importers and their inspection agencies to guarantee product quality. The most effective approach involves implementing a three-stage quality control framework with AQL sampling standards.

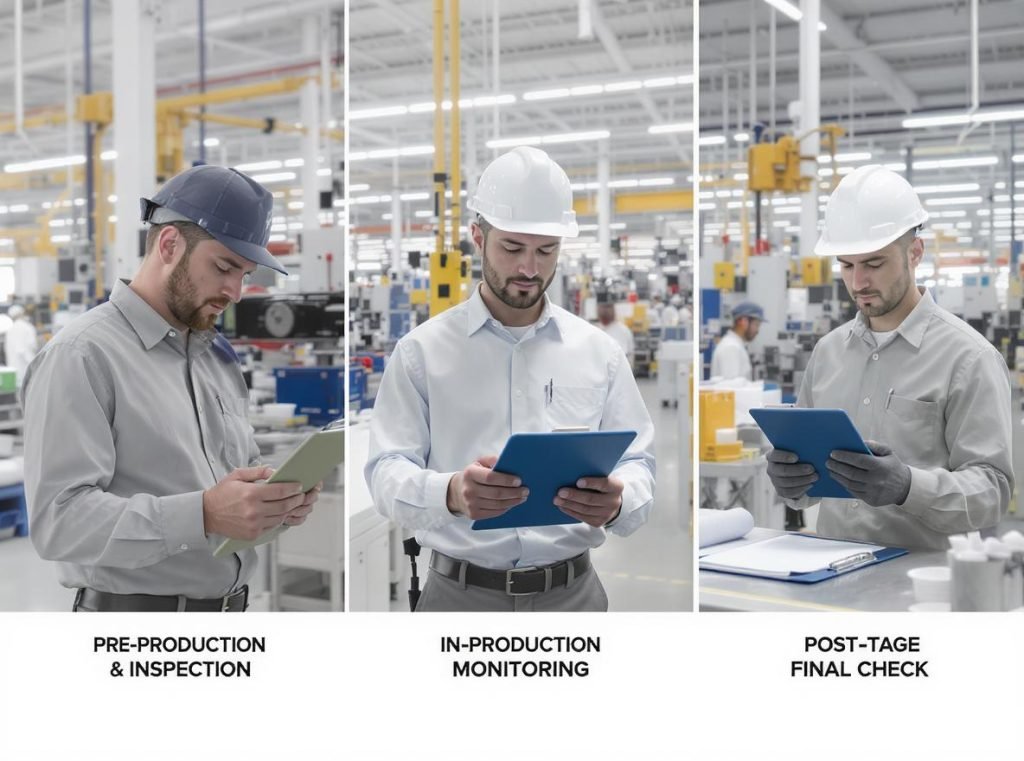

Three-Stage Quality Control Framework

Pre-production inspections verify that materials, components, and initial setup meet specifications before mass production begins. In-production inspections monitor manufacturing processes during production to catch issues early. Post-production inspections provide the final quality assessment before shipment.

This systematic approach creates multiple opportunities to identify and correct quality issues before they reach your customers.

AQL Sampling Standards

AQL (Acceptable Quality Limit) is an internationally acceptable quality inspection measure representing the maximum number of defects per hundred units in a sample. For most general consumer products, the standard AQL levels are:

- Critical defects: 0% tolerance – defects that fail to meet mandatory regulations or affect consumer safety

- Major defects: 2.5% tolerance – defects that lead to product failure or significant reduction in usability

- Minor defects: 4.0% tolerance – defects that show deviation from specifications but don’t affect functionality

Statistical Process Control

Statistical Process Control (SPC) is one of the most common quality control methods used in Chinese manufacturing. It uses control charts, Pareto charts, and histograms as statistical tools to monitor data during production, making the data visible and allowing quick responses to data changes.

| Inspection Stage | AQL Standard | Key Focus Areas |

|---|---|---|

| Pre-production | 0% critical defects | Material verification, setup validation |

| In-production | 2.5% major defects | Process monitoring, dimensional checks |

| Pre-shipment | 4.0% minor defects | Final quality assessment, packaging inspection |

How Important Are Supplier Audits and Certifications?

Supplier audits play a vital role in ensuring quality assurance and compliance throughout your supply chain, providing independent assessment of supplier capabilities and processes.

A supplier audit is an independent and objective assessment of a supplier’s processes or products against benchmarked criteria. Regular quality audits help identify whether suppliers are meeting needed quality standards at any given point in time.

Types of Supplier Audits

Quality system audits evaluate the supplier’s quality management system to ensure it meets defined standards and regulatory requirements. Process audits focus on specific processes within the supplier’s operations to assess their efficiency and effectiveness. Product audits involve inspecting and evaluating the quality of the supplier’s products or services.

Factory Capability Assessment

Audit your supplier’s facilities to understand their true capabilities. Look at equipment condition, maintenance programs, production capacity, and quality management systems. Check for documented procedures, training programs, and quality control measures.

Certification Verification

Suppliers are considered an extension of your company, which means they all need to be evaluated, audited, and monitored. A best practice for supplier management is keeping a record of the supplier’s ISO certificate on file.

During audits, procurement teams quality-check goods received from suppliers and review the supplier’s facilities and processes for any loopholes and opportunities for improvement.

What Role Does Technology Play in Quality Monitoring?

Technology plays an increasingly critical role in modernizing quality control processes and enabling real-time monitoring capabilities that enhance quality consistency.

Digital quality control means performing quality control checks using a digital solution rather than paper checklists and forms. Digital quality management systems (DQM) provide tools and processes to monitor and verify that product and process quality meets expectations.

Digital Quality Management Systems

DQM provides a systematic and automated framework for monitoring, ensuring, and enhancing quality. Key benefits include:

- Automated reporting: Reduces likelihood of human errors and provides real-time insights for timely decisions

- Real-time monitoring: Enables immediate detection of quality issues during production

- Data analytics: Facilitates trend analysis and predictive quality management

- Documentation control: Ensures comprehensive record-keeping and traceability

Advanced Inspection Technologies

Automated inspection systems equipped with high-resolution cameras and sensors can perform detailed checks at a speed and accuracy unattainable by human inspectors. AI-driven analytics can sift through vast amounts of production data to predict quality deviations, allowing preemptive corrective actions.

Mobile Quality Control Applications

With digital quality control software, brands and retailers can capture accurate and reliable data on the factory floor. Quality managers can exactly define the processes to follow, monitor inspector work in real time, and receive interactive reports immediately after inspections are completed.

How Do You Handle Quality Issues When They Occur?

When quality issues arise, swift and systematic response is crucial to prevent escalation and recurrence while maintaining supplier relationships.

The goals of a corrective action policy are to identify the root cause of problems, correct nonconformities, implement solutions to avoid recurrence, and maintain the highest level of quality. Corrective action is a process implemented to identify, rectify, and eliminate causes of detected non-conformities.

Immediate Response Protocols

When quality issues are discovered, act quickly to contain the problem. Stop shipment of defective products and assess the extent of the issue. When issues arise, it’s vital to take immediate corrective actions to mitigate risks and prevent further problems.

Systematic Corrective Action Process

The corrective action process involves:

- Immediate containment: Stop production if necessary and assess issue scope

- Root cause analysis: Investigate fundamental reasons behind quality failure

- Corrective action planning: Develop specific actions addressing root causes

- Implementation: Execute corrective measures with clear timelines and responsibilities

- Verification: Confirm effectiveness through follow-up inspections

Supplier Corrective Action Requests (SCARs)

Supplier Corrective Action Requests (SCARs) count the number of corrective action requests issued to suppliers due to quality issues. Monitoring SCARs helps assess supplier responsiveness and effectiveness in addressing quality concerns.

Effective communication during quality issues should include clear documentation of problems, immediate notification to affected parties, collaborative problem-solving with suppliers, timeline establishment for resolution, and progress monitoring.

What Are the Benefits of Long-Term Supplier Relationships?

Building strong, long-term relationships with Chinese suppliers offers significant advantages for quality consistency and operational efficiency.

Long-term contracts foster stronger relationships with key suppliers, leading to better communication and deeper understanding of each other’s needs. By establishing mutually valuable relationships, organizations can achieve long-term cost savings through reduced issues with availability, quality, and delays.

Quality Improvements Through Partnership

Good working relationships with suppliers deliver cost savings and reduce availability problems, delays, and quality issues – meaning better service for consumers. As relationships develop, suppliers get to know more about your organization, enabling them to increase service efficiency.

Enhanced Communication Benefits

Long-term relationships create comfortable communication channels where suppliers are more likely to proactively communicate about potential issues or suggest improvements. This leads to:

- Reduced misunderstandings about quality requirements

- Faster resolution of quality issues

- Proactive problem prevention based on shared experience

- Continuous improvement initiatives

Supply Chain Stability

Long-term agreements often mean steady flow of materials, reducing the risk of shortages that could halt production. This reliability is crucial for maintaining consistent production schedules and quality standards.

| Partnership Benefit | Impact on Quality | Business Value |

|---|---|---|

| Better communication | Reduced misunderstandings | Fewer quality issues |

| Shared investment | Improved processes | Cost savings |

| Supply stability | Consistent materials | Reliable production |

| Continuous improvement | Enhanced standards | Competitive advantage |

How Can Professional Quality Control Services Help?

Professional third-party quality control services provide expertise and objectivity that can significantly enhance quality consistency across multiple orders from China.

Quality control inspections are very helpful for clients to prevent heavy losses. Professional quality control inspection services ensure customer satisfaction by providing unparalleled edge in the market through objective assessment and technical expertise.

Third-Party Inspection Services

Professional quality control companies offer comprehensive services including:

- Factory capability audits to assess supplier qualifications

- Pre-shipment inspections to verify product quality before delivery

- Pre-production and final random sampling inspections to monitor quality at critical stages

- Container loading supervision to ensure proper handling and protection

- Laboratory testing services for technical compliance verification

Advantages of Professional Services

Key benefits include:

- Objective assessment: Independent evaluation free from supplier bias

- Technical expertise: Specialized knowledge of industry standards and testing methods

- Local presence: On-ground inspectors familiar with Chinese manufacturing practices

- Comprehensive reporting: Detailed documentation with photographic evidence

- Rapid response: Fast turnaround times for inspection reports and corrective actions

Service Selection Criteria

When choosing quality control services, consider geographic coverage across key manufacturing regions in China, industry specialization relevant to your product categories, accreditation and certifications of testing laboratories, reporting speed and quality of inspection documentation, and integration capabilities with your quality management systems.

What Implementation Strategy Should You Follow?

Successfully ensuring consistent quality across multiple orders requires a phased implementation approach that builds systematically on foundational elements.

Implementing effective quality control requires progressive development from basic standards to advanced monitoring systems. The key lies in combining systematic processes, technological tools, and collaborative partnerships to create a robust quality assurance framework.

Phase 1: Foundation Building

Establish clear quality standards and specifications, implement supplier qualification processes, and set up basic quality control checkpoints. This phase focuses on creating the fundamental framework for quality management.

Phase 2: System Integration

Deploy digital quality management systems, integrate AQL sampling methodologies, and establish corrective action procedures. This phase systematizes your quality control processes and creates consistent monitoring capabilities.

Phase 3: Technology Enhancement

Implement advanced monitoring technologies, develop comprehensive data analytics capabilities, and optimize quality control processes based on performance data. This phase leverages technology to enhance quality visibility and predictive capabilities.

Phase 4: Partnership Development

Invest in supplier development programs, establish collaborative quality improvement initiatives, and create shared quality objectives and metrics. This phase builds the relationship foundation for long-term quality consistency.

Summary

Ensuring consistent quality across multiple orders from China requires systematic planning, clear communication, and ongoing vigilance. Success depends on establishing detailed specifications, implementing comprehensive quality control systems using AQL standards, building strong supplier relationships, and maintaining continuous improvement processes through technology and professional services.

Ready to ensure consistent quality for your packaging orders from China? Contact Acreet today for expert guidance on implementing effective quality control systems that protect your brand reputation and satisfy your customers with every order.