Choosing the wrong flute size for your corrugated boxes can lead to damaged products, increased shipping costs, and unhappy customers. With flute options ranging from micro-flutes like E and F to heavy-duty A-flute configurations, making the right choice affects everything from product protection to printing quality and overall packaging efficiency.

The right flute size depends on your specific packaging needs: E-flute (1.6mm thick) excels for lightweight items requiring high-quality printing, B-flute (3.2mm thick) provides excellent crush resistance for retail applications, and C-flute (4.0mm thick) offers superior stacking strength for general shipping. Consider your product weight, shipping distance, stacking requirements, and printing needs when selecting the optimal flute configuration.

Understanding these differences will help you make informed decisions that protect your products while optimizing costs and presentation quality.

Table of Contents

ToggleWhat Are Corrugated Flutes and Why Do They Matter?

Many businesses don’t realize that the wavy internal structure of their packaging boxes significantly impacts product protection and shipping success.

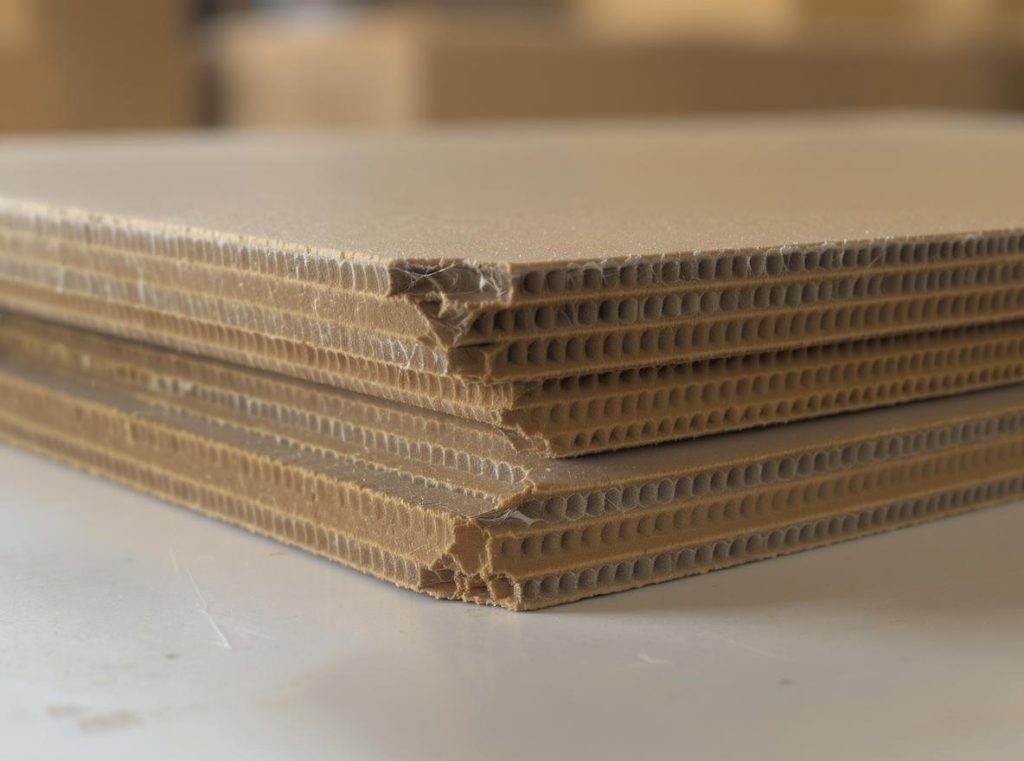

Corrugated flutes are the wave-shaped arches that form the middle layer of corrugated board, sandwiched between two flat linerboards and secured with adhesive. These flutes function as rigid columns when viewed from the end, capable of supporting substantial weight, while from the side they act as cushions to protect contents during shipping and handling.

The flute structure provides several critical functions that directly impact your packaging performance:

Structural Strength: Flutes create compression resistance through their column-like architecture. When boxes are stacked, the flutes distribute weight evenly, preventing crushing and maintaining structural integrity during storage and transport.

Cushioning Properties: The wave-shaped design acts as a shock absorber, protecting contents from impacts and vibrations during handling. This cushioning effect is crucial for fragile items that need protection from rough handling.

Thermal Insulation: The air spaces within flutes provide insulation from temperature changes, helping maintain product integrity during shipping through varying climates.

Printing Surface: Different flute sizes create varying surface smoothness levels, directly affecting print quality and brand presentation capabilities.

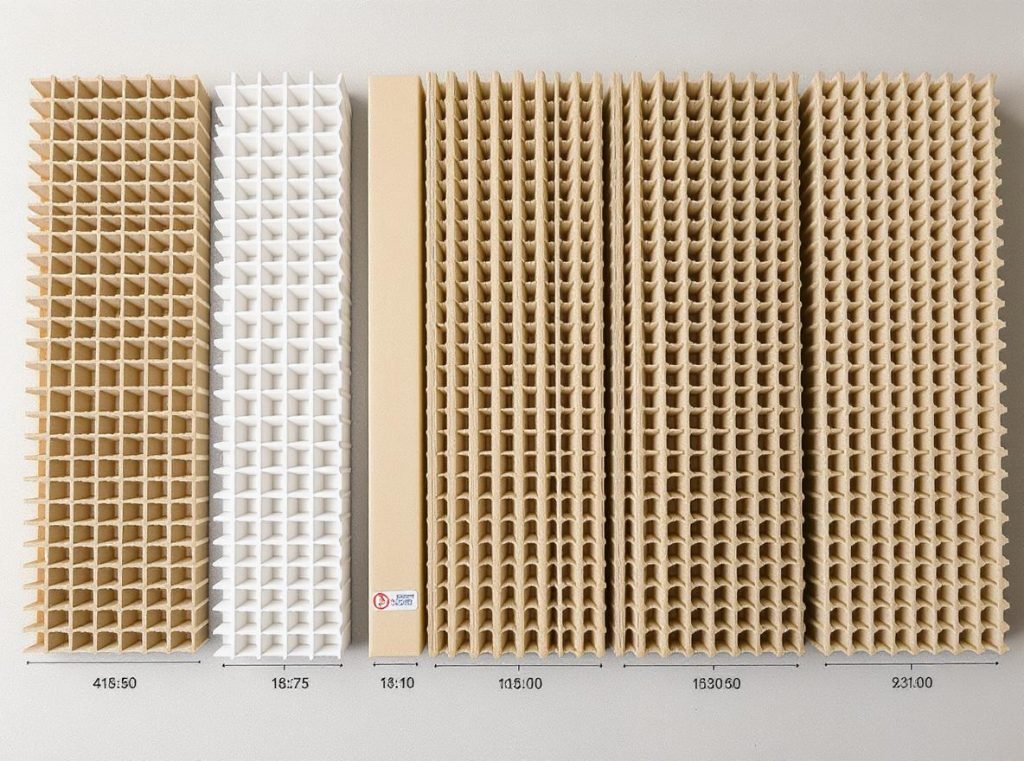

The alphabetical designations (A, B, C, E, F) are based on the order of invention rather than size hierarchy. A-flute was developed first, followed by B-flute, then C-flute was created as an intermediate size, with E and F emerging later as micro-flute options for specialized applications.

What Is E-Flute and When Should You Use It?

E-flute represents the micro-flute category, designed specifically for applications requiring superior print quality and lightweight protection.

E-flute measures approximately 1.6 millimeters (1/16 inch) in thickness with about 90-98 flutes per linear foot. This high flute density creates an exceptionally smooth surface ideal for high-quality printing applications, while providing excellent crush resistance and precise folding capabilities for complex die-cut designs.

E-flute excels in several key performance areas:

Superior Printability: The high flute density minimizes flute show-through, creating a smooth printing surface that accepts fine details, sharp text, and vibrant colors. This makes E-flute an excellent alternative to traditional paperboard folding cartons.

Lightweight Efficiency: The thin profile reduces material usage and shipping weight, making it cost-effective for products that don’t require heavy-duty protection. This efficiency is particularly valuable for e-commerce applications where shipping costs are critical.

Precision Folding: E-flute’s structure allows for precise folding and complex die-cut designs, enabling sophisticated packaging shapes and configurations that wouldn’t be possible with thicker flutes.

| E-Flute Applications | Why E-Flute Works Best |

|---|---|

| Retail packaging | Superior print quality for brand presentation |

| Point-of-purchase displays | Smooth surface for high-quality graphics |

| E-commerce mailers | Lightweight yet protective for small items |

| Cosmetics packaging | Premium appearance with adequate protection |

| Pizza boxes | Precise folding for tight seals |

E-flute is not recommended for heavy-duty shipping applications or products requiring maximum cushioning, as its thin profile limits protective capabilities for heavy or fragile items.

What Is B-Flute and What Are Its Best Applications?

B-flute strikes the optimal balance between structural strength and printing quality, making it versatile for diverse packaging requirements.

B-flute measures approximately 3.2 millimeters (1/8 inch) in thickness with 47-50 flutes per linear foot. Originally developed for packaging canned goods, B-flute provides excellent crush resistance with more flute contact points than larger flutes, while maintaining a smooth surface ideal for high-quality printing and die-cutting operations.

B-flute’s balanced characteristics make it suitable for multiple applications:

Excellent Crush Resistance: The medium flute density provides superior resistance to crushing forces, making it ideal for products that may experience pressure during handling or storage.

Versatile Processing: B-flute processes efficiently on high-speed automatic packing lines due to its balanced structural properties, reducing production bottlenecks and improving manufacturing efficiency.

Space Optimization: B-flute consumes less warehouse space than larger flutes while providing adequate protection, making it valuable for operations where storage costs are significant.

The versatility of B-flute makes it particularly suitable for:

- Corrugated mailers requiring both protection and print quality

- Retail packaging where brand presentation matters

- Beverage trays and wrap-around applications

- Inner packaging components like pads and dividers

- Die-cut specialty packaging requiring precise folding

B-flute represents the sweet spot for applications requiring both structural integrity and premium appearance, making it ideal for products that need protection without sacrificing brand presentation.

What Is C-Flute and When Is It the Right Choice?

C-flute dominates the corrugated packaging industry as the most widely used flute size, accounting for approximately 80% of all corrugated containers.

C-flute measures approximately 4.0 millimeters (11/64 inch) in thickness with 39-43 flutes per linear foot. This configuration provides balanced performance combining cushioning properties with stacking strength, making it the versatile choice for most general packaging applications while maintaining acceptable printing properties.

C-flute’s widespread adoption stems from several key advantages:

Optimal Stacking Strength: The medium-sized flute structure provides excellent vertical compression resistance, allowing boxes to be stacked high without crushing lower packages. This is crucial for warehouse storage and shipping containers.

Balanced Cushioning: C-flute offers superior shock absorption compared to smaller flutes, effectively protecting contents from impacts during handling and shipping while maintaining structural integrity.

Cost-Effectiveness: C-flute represents the best value proposition for general shipping applications, providing adequate protection at reasonable material costs without over-engineering the packaging.

Universal Compatibility: The standard thickness works well with most packaging equipment and fulfillment systems, making it the safe choice for operations with mixed product lines.

| Flute Comparison | Thickness | Flutes/Foot | Primary Strength | Best Use Case |

|---|---|---|---|---|

| E-Flute | 1.6mm | 90-98 | Crush resistance | Lightweight retail |

| B-Flute | 3.2mm | 47-50 | Balanced | Food/retail packaging |

| C-Flute | 4.0mm | 39-43 | Stacking | General shipping |

| A-Flute | 4.8mm | 33-39 | Cushioning | Heavy-duty protection |

C-flute serves as the industry standard because it handles the majority of packaging challenges effectively without requiring specialized solutions.

How Do You Match Flute Size to Your Product Requirements?

Selecting the optimal flute size requires systematic analysis of your specific product characteristics and supply chain requirements.

Consider product weight, fragility, shipping distance, stacking requirements, and printing needs when choosing flute sizes. Lightweight products under 5 pounds work well with E-flute, medium-weight items (5-20 pounds) suit B-flute or C-flute, and heavy-duty applications over 20 pounds typically require A-flute or double-wall constructions for maximum protection.

Follow this comprehensive evaluation process:

Weight-Based Selection: Start with product weight as your primary criterion. Lightweight items under 5 pounds can utilize E-flute or F-flute effectively, providing adequate protection while minimizing material costs and shipping weight.

For medium-weight products (5-20 pounds), B-flute or C-flute offer the ideal balance of strength and efficiency. C-flute works well for standard shipping applications, while B-flute provides better printing quality when brand presentation is important.

Heavy-duty applications over 20 pounds typically require A-flute’s maximum cushioning properties, with its 4.8-5.0 millimeter thickness providing superior protection for fragile items during long-distance shipping.

Stacking Requirements Assessment: Compression strength follows the hierarchy A > C > B > E > F. However, larger flutes provide greater strength but with increased deformation under load, while smaller flutes reduce deformation but offer lower absolute strength.

Shipping Distance Considerations: Longer shipping distances with more handling points favor stronger flutes. Local deliveries might accommodate lighter flute options, while international shipping typically requires more robust protection due to extended handling periods.

Printing Quality Requirements: For high-quality graphics requiring sharp text and vibrant colors, E-flute and F-flute provide the smoothest surfaces with minimal flute show-through. B-flute offers good compromise between printability and structural strength, while C-flute provides acceptable printing properties for standard applications.

What About Double-Wall and Specialty Flute Combinations?

When single-wall corrugated doesn’t provide sufficient protection, double-wall and triple-wall constructions offer enhanced performance through strategic flute combinations.

Double-wall corrugated consists of two layers of fluting between three layers of liner board, creating a 5-ply construction that significantly increases strength, stability, and insulation. Triple-wall features three flute layers between four liner boards, creating 7-ply construction capable of handling loads up to 500 kilograms.

The most effective double-wall combinations include:

BC-Flute Combination: The most popular double-wall configuration combines B-flute’s printing advantages on the outer layer with C-flute’s cushioning properties internally. This combination leverages the strengths of both flute types while minimizing weaknesses.

EB-Flute Combination: Pairs E-flute’s superior printability with B-flute’s structural strength, creating packaging that excels in both visual appeal and protection. This combination is particularly effective for retail-ready packaging requiring premium presentation.

EE-Flute Combination: Provides balanced performance with excellent printability on both surfaces, making it ideal for specialized display applications where both sides may be visible.

Triple-wall constructions serve the most demanding applications:

- Heavy machinery packaging requiring maximum protection

- International shipping where packages face extended handling

- Industrial components needing robust protection

- Large glassware and fragile high-value items

Specialty micro-flute combinations like F-flute and N-flute are gaining popularity for applications requiring elegant presentation and environmental sustainability. These combinations offer reduced fiber consumption for smaller carbon footprints while maintaining enhanced printability and improved folding accuracy.

How Can You Test and Optimize Your Flute Selection?

Proper testing ensures your chosen flute configuration performs reliably throughout the supply chain while optimizing protection and costs.

Start with small test batches using different flute sizes under actual shipping conditions. Monitor damage rates, customer feedback, and total packaging costs including materials, shipping impacts, and damage replacement expenses. Use standardized testing methods like Bursting Strength, Edge Crush, and Box Compression tests to validate performance objectively.

Implement these essential testing methods:

Bursting Strength Test (Mullen Test): Measures material resistance to pressure by applying hydraulic force until the corrugated board bursts. This test determines exact weight capacity and helps predict performance under rough handling conditions.

Edge Crush Test (ECT): Evaluates compression strength by applying crushing force to corrugated sample edges. This test is crucial for determining stacking strength since edges are typically the first failure points during handling.

Box Compression Test: Measures the maximum load a complete box can withstand before deformation. This comprehensive test simulates real-world stacking conditions and helps optimize packaging for warehouse storage requirements.

Puncture Resistance Test: Determines the force required to penetrate corrugated material using a standardized triangular pyramid puncture head. This test is essential for packages that may encounter sharp objects during handling.

Performance Optimization Strategies:

Use an iterative testing approach starting with the thinnest flute meeting basic requirements, then test progressively thicker options until optimal performance is achieved. This ensures you’re not over-packaging while maintaining adequate protection.

Conduct supply chain simulation testing that replicates actual shipping conditions, including vibration, temperature changes, humidity exposure, and handling stress. ISTA-certified testing procedures provide standardized protocols for various shipping scenarios.

Balance material costs against potential product damage and customer satisfaction through comprehensive cost-benefit analysis. Sometimes investing in slightly thicker flutes can significantly reduce damage claims and improve brand reputation.

Summary

Choosing the right corrugated flute size significantly impacts packaging success, shipping costs, and customer satisfaction. E-flute (1.6mm) excels for lightweight items requiring excellent print quality, B-flute (3.2mm) offers versatility for retail and moderate-weight products, C-flute (4.0mm) provides superior stacking strength for general shipping, and A-flute (4.8mm) delivers maximum cushioning for heavy-duty applications. Consider product weight, shipping requirements, stacking needs, and printing quality when making your selection.

Ready to optimize your packaging with the perfect flute configuration? Contact Acreet today for expert guidance on selecting the ideal corrugated solutions for your specific requirements. Our experienced packaging engineers can help you balance protection, cost, and presentation to create packaging that protects your products while enhancing your brand. Send us your product specifications and shipping requirements for a customized flute recommendation and competitive quote.