Poor packaging quality can destroy your brand reputation overnight. One damaged product, one inconsistent design, or one structural failure can lead to customer complaints, returns, and lost sales. Your business depends on packaging that protects, presents, and performs consistently every single time.

A comprehensive quality control checklist for packaging should include physical integrity verification, material quality assessment, labeling accuracy checks, sealing performance tests, and regulatory compliance validation. This systematic approach ensures every package meets your brand standards and customer expectations before reaching the market.

Let’s explore how to build a bulletproof quality control system that protects your brand and satisfies your customers.

Table of Contents

ToggleWhat Are the Essential Components of a Packaging Quality Control Checklist?

Understanding the core elements helps you build a systematic approach that covers all critical quality aspects. Without these fundamental components, your quality control efforts will have gaps that could compromise your entire operation.

Your packaging quality control checklist must cover five critical areas: physical integrity and dimensions, material quality specifications, labeling and identification accuracy, sealing and closure performance, and regulatory compliance verification. Each component addresses specific quality risks and ensures comprehensive coverage of potential issues.

Physical Integrity and Dimensions

Physical integrity forms the foundation of reliable packaging protection. Your checklist should verify exact dimensional specifications and structural soundness.

Key physical checkpoints include:

- Clear and legible shipping marks on outer and inner cartons

- Correct purchase order information on shipping marks

- Proper carton markings without damage or defects

- Accurate package size and dimensions within tolerance

- Verification of product variety and quantity per carton

| Dimension Check | Tolerance Range | Inspection Method | Frequency |

|---|---|---|---|

| Length/Width | ±1-3mm | Caliper measurement | Every batch |

| Height | ±1-3mm | Digital measuring | Per production run |

| Wall Thickness | ±0.5mm | Micrometer | Daily sampling |

Material Quality and Specifications

Material consistency directly impacts packaging performance and brand perception. Your checklist must verify that packaging materials match approved specifications and signed samples.

Critical material verification includes matching package printing, materials, contents, size, and color with approved samples. Assess material durability and structural integrity through standardized testing protocols.

Proper packaging material selection based on product requirements ensures optimal protection. Verify correct packing materials usage and evaluate adhesive bond strength for multi-layer constructions.

Labeling and Identification Systems

Brand consistency and regulatory compliance depend on accurate labeling. Your checklist should cover all identification elements that appear on packaging.

Essential labeling checks include:

- Complete and accurate distributor information

- Proper logo, hangtag, or warning label placement

- Correct product codes and expiry dates

- Barcode quality and readability verification

- Compliance with regulatory labeling requirements

Color tolerances are critical for brand recognition and should be defined using Delta E (ΔE) values. Maintain color differences below ΔE 2.0 for critical brand colors to ensure consistent appearance.

Sealing and Closure Performance

Package security depends on proper sealing and closure functionality. Your checklist must verify seal integrity and tamper-evident features.

Key sealing assessments include:

- Package securely sealed with appropriate seal strength

- Verification of safety seals and tamper-evident features

- Testing of closure functionality and ease of opening

- Seal strength testing under various conditions

- Leak testing for sealed packages

How Do You Establish Quality Standards and Tolerances?

Setting clear, measurable standards prevents subjective quality decisions and ensures consistent results across all production batches. Your team needs specific criteria to evaluate every package effectively.

Quality standards should be based on industry benchmarks, customer requirements, and regulatory compliance needs. Establish numerical tolerances for measurable attributes and detailed acceptance criteria for subjective qualities, including acceptable quality limits (AQL) for different defect categories.

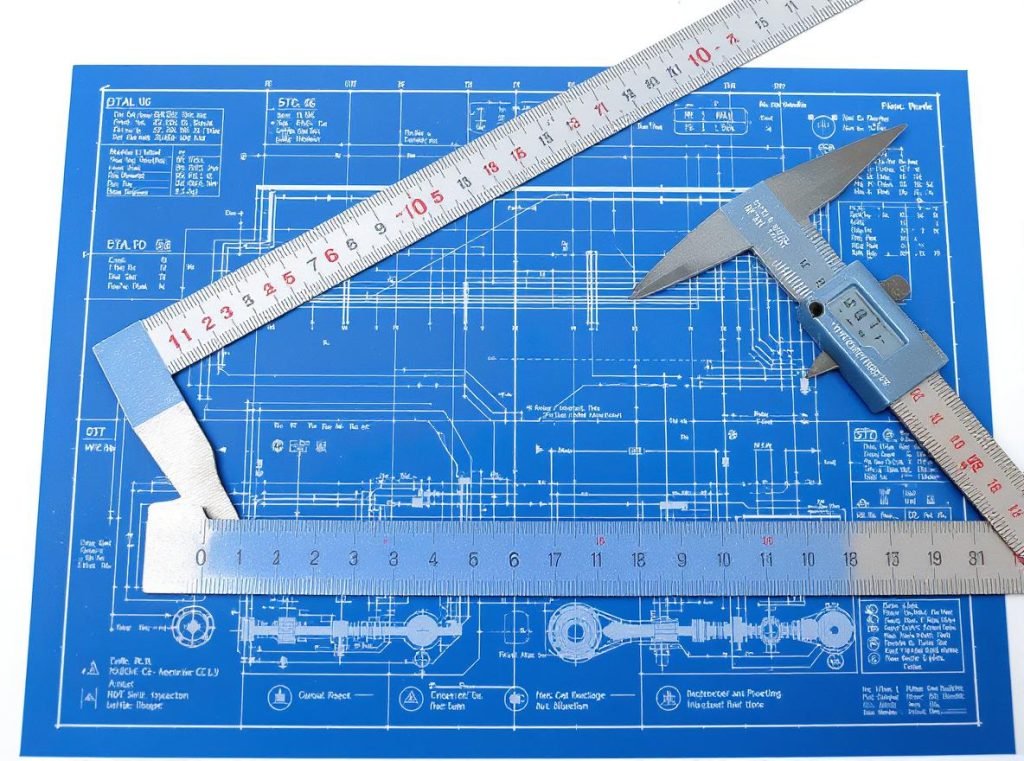

Defining Measurable Quality Metrics

Quantifiable standards eliminate interpretation errors and provide clear pass/fail criteria. Your checklist should include specific measurements for dimensions, weights, and performance characteristics.

Dimensional tolerances typically range from ±1-3mm depending on package size and application. Weight variations should stay within ±2% of specified values for consistent material usage and shipping cost control.

Performance tolerances include acceptable quality limits (AQL) for different defect categories. Packaging inspection standards may specify maximum allowable minor defects, major defects, and critical defects based on lot size.

Creating Performance Benchmarks

Performance standards ensure your packaging functions correctly under normal use conditions. Test criteria should reflect real-world usage scenarios and transportation stresses.

| Performance Test | Acceptance Criteria | Test Method | Sample Size |

|---|---|---|---|

| Compression Strength | >90% of specification | ASTM D642 | 5 per batch |

| Drop Test | No structural failure | ISTA 2A | 10 packages |

| Seal Strength | 2-5 N/cm peel force | ASTM F88 | 3 per production run |

Your benchmarks should include minimum compression strength for stacking loads, maximum moisture absorption rates, and specific temperature resistance ranges. Document these requirements clearly for consistent testing execution.

Establishing Tolerance Categories

Different defect types require different tolerance levels based on their impact on functionality and appearance. Critical defects affect safety or regulatory compliance and require zero tolerance.

Major defects impact functionality or significantly affect appearance, while minor defects have minimal impact on performance. Establish clear definitions and acceptable limits for each category.

What Testing Methods Should You Include in Your Checklist?

Effective testing methods provide reliable, repeatable results that accurately predict packaging performance under real-world conditions. Your checklist should specify exact testing procedures and equipment requirements.

Include both destructive and non-destructive testing methods in your checklist. Non-destructive tests like visual inspection and dimensional measurement allow 100% inspection, while destructive tests like drop testing and compression testing verify maximum performance limits on sample batches.

Physical and Mechanical Testing

Physical testing validates packaging’s ability to withstand transportation and handling stresses. These tests simulate real-world conditions that packages encounter during their lifecycle.

Drop testing simulates impacts during shipping by dropping packages from predetermined heights. This test validates package integrity and product protection capabilities under sudden impact forces.

Compression testing evaluates packaging’s ability to withstand stacking loads and storage pressures. This is crucial for warehouse storage and transportation where packages may be stacked multiple layers high.

Vibration testing assesses package durability during transport by subjecting packages to controlled vibrations that simulate shipping conditions. This identifies potential weak points that could fail during extended transportation.

Barrier and Functional Testing

Barrier properties protect products from environmental factors like moisture, oxygen, and light. Your testing program should verify these protective characteristics.

Water Vapor Transmission Rate (WVTR) testing measures packaging permeability to water vapor under specific temperature, pressure, and humidity conditions. This is critical for products sensitive to moisture.

Oxygen Transmission Rate (OTR) testing measures oxygen permeability through packaging materials, essential for products that degrade when exposed to oxygen.

Seal strength testing verifies the integrity of package seals over time and under various conditions. This includes peel strength testing and burst testing to ensure seals maintain integrity throughout the product lifecycle.

Environmental and Compliance Testing

Environmental testing validates packaging performance under various storage and transportation conditions. Climate conditioning tests packaging performance under different temperature and humidity ranges.

Migration testing assesses potential chemical migration from packaging materials into products, particularly important for food and pharmaceutical applications where contamination could pose health risks.

Burst and puncture testing evaluates packaging resistance to sudden pressure increases and sharp object penetration. This ensures packages can withstand rough handling during shipping and storage.

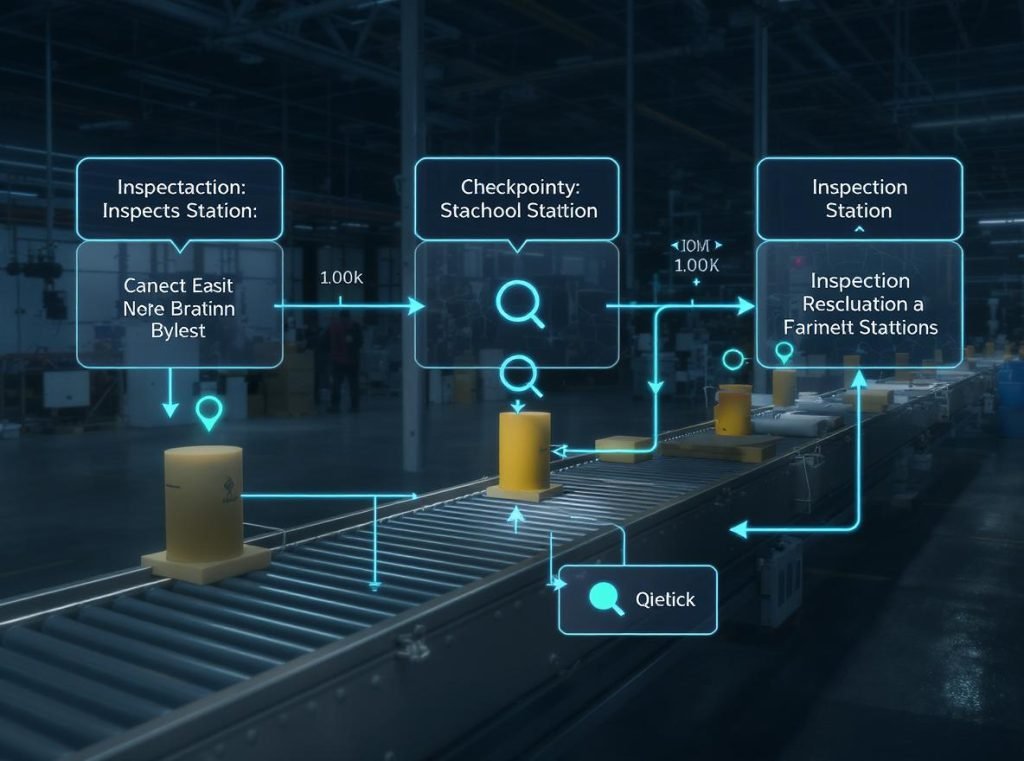

How Do You Implement Quality Control Checkpoints in Production?

Strategic checkpoint placement catches quality issues before they multiply throughout production. Your system should balance thorough inspection with efficient workflow to maintain productivity.

Implement quality checkpoints at four critical stages: upon receipt of materials, during production setup, throughout production monitoring, and pre-shipment inspection. Each checkpoint should have specific responsibilities, testing requirements, and decision-making authority to maintain quality standards.

Incoming Material Inspection

Material quality directly impacts final product performance. Inspect all incoming materials before they enter production to prevent quality issues from propagating through the entire batch.

Your incoming inspection should verify that packaging components meet specifications and match approved samples. Check material quality, dimensions, and compliance with technical requirements.

Create material approval processes that require supplier certifications and test results. This reduces inspection time while maintaining quality standards and establishes clear accountability with suppliers.

Initial Production Checks (IPC)

Initial Production Checks verify that packaging materials and processes meet specified standards at the onset of production. This prevents entire production runs from being compromised by setup errors.

Key setup verification includes:

- Machine calibration and parameter settings

- Tool wear assessment and replacement needs

- First article inspection and approval

- Process parameter confirmation and documentation

- Quality measurement system calibration checks

In-Process Quality Monitoring

Continuous monitoring during production catches quality drift before it creates significant problems. Establish sampling frequencies based on production volume and historical quality data.

Monitor critical quality parameters throughout production runs using statistical process control methods. This helps identify trends before they become quality problems requiring corrective action.

Implement automated quality control systems including vision inspection systems with cameras and sensors for detecting misprints, color inconsistencies, and physical damage in real-time.

Pre-Shipment Final Inspection

Final inspection provides the last opportunity to catch quality issues before products reach customers. Your final inspection should verify all critical quality characteristics and order accuracy.

Conduct comprehensive quality checks on finished packaged products, including seal integrity, labeling accuracy, and overall package condition. Perform container loading checks to ensure correct packaging, quantities, and order details.

| Final Inspection Element | Check Method | Acceptance Criteria | Documentation Required |

|---|---|---|---|

| Seal Integrity | Visual + pressure test | No visible defects | Pass/fail record |

| Label Accuracy | Barcode scan + visual | 100% accuracy | Verification log |

| Package Condition | Visual inspection | No damage/defects | Inspection checklist |

How Do You Train Your Team on Quality Control Procedures?

Effective quality control depends on well-trained personnel who understand procedures, standards, and their critical role in maintaining quality. Your training program should be comprehensive and ongoing.

Develop a structured training program that includes orientation training, technical skill development, regulatory compliance education, and continuous learning opportunities. Training should cover quality standards, testing methods, documentation requirements, and escalation procedures for non-conforming products.

Structured Training Program Components

Orientation training provides general information for new employees about quality standards, company policies, and their role in maintaining quality. This establishes the foundation for quality-focused thinking.

Technical training includes job-specific instruction on quality control procedures, testing methods, and equipment operation. Provide hands-on practice with actual production samples and equipment.

Regulatory training ensures staff understand relevant regulations and compliance requirements for your industry. This is particularly important for food, pharmaceutical, and consumer product packaging.

Training Implementation Strategies

Develop annual training schedules with specific topics, target audiences, and timing. Include both theoretical knowledge and practical application to ensure competency.

Utilize multiple training methods including lectures, on-the-job training, educational materials, and multimedia presentations. Different learning styles require different approaches for maximum effectiveness.

Create standardized training materials and procedures to ensure consistency across all training sessions. Use visual aids, checklists, and reference guides to support learning retention.

Competency Assessment and Validation

Regularly assess training effectiveness through questionnaires, performance evaluations, and practical demonstrations. This ensures training objectives are being met.

Implement competency testing that requires employees to demonstrate proficiency in their assigned quality control tasks. Document all competency assessments and maintain training records.

Establish retraining requirements for employees who don’t meet competency standards. Provide additional support and practice opportunities to ensure all team members can perform their roles effectively.

What Documentation and Record-Keeping Requirements Should You Include?

Proper documentation provides quality traceability, supports regulatory compliance, and enables continuous improvement efforts. Your documentation system should capture all critical quality information.

Your quality control checklist should require comprehensive documentation of test results, non-conformance issues, corrective actions, and trend analysis. Maintain records that support quality investigations, customer inquiries, and regulatory compliance requirements with appropriate retention periods.

Essential Quality Documentation

Technical documentation must include detailed records of packaging specifications, approved samples, and design requirements. This documentation serves as the reference standard for all quality decisions.

Quality control records should document all inspection activities, test results, and corrective actions taken. Include photographic evidence of defects and non-conformances for clear communication and future reference.

Traceability records enable tracking of packaging batches from raw materials to final products. This capability enables rapid response to quality issues and supports root cause analysis when problems occur.

Digital Record-Keeping Systems

Implement electronic record-keeping systems for better organization, searchability, and backup capabilities. Digital systems improve accessibility and reduce the risk of lost documentation.

Maintain clear audit trails showing who performed inspections, when they were completed, and what actions were taken. This accountability supports quality investigations and regulatory audits.

Create standardized documentation formats and templates to ensure completeness and accuracy. Consistent formats make record review and analysis more efficient.

Regulatory Compliance Documentation

Regulatory requirements may specify quality documentation and record-keeping obligations. Your system should capture all required information and maintain records for specified retention periods.

Common regulatory requirements include material certifications, test reports, and change control documentation. Regular internal audits verify compliance with applicable regulations.

Establish appropriate record retention periods based on regulatory requirements and business needs. Some industries require quality records to be maintained for several years after product shipment.

How Do You Continuously Improve Your Quality Control Process?

Continuous improvement ensures your quality control system evolves with changing requirements, technology advances, and industry best practices. Regular review and updates maintain effectiveness and efficiency.

Implement a systematic improvement process using the Plan-Do-Check-Act (PDCA) cycle to analyze quality data, identify trends, and implement corrective actions. Use customer feedback, internal metrics, and industry benchmarks to guide improvement priorities and measure progress.

Systematic Improvement Methodologies

The Plan-Do-Check-Act (PDCA) cycle provides a structured approach to continuous improvement. Identify improvement opportunities, implement changes on a small scale, analyze results, and scale successful improvements.

Root cause analysis investigates quality issues to identify underlying causes rather than just addressing symptoms. This prevents recurring problems and improves overall system effectiveness.

Statistical process control uses statistical methods to monitor process performance and identify trends before they become problems. This proactive approach prevents quality issues rather than just detecting them.

Data-Driven Improvement Strategies

Establish key performance indicators (KPIs) to track quality performance, including defect rates, customer complaints, and process efficiency. Regular monitoring reveals improvement opportunities.

Customer feedback integration provides valuable insights into quality performance under real-world conditions. Use customer complaints and suggestions to validate quality standards and identify improvement priorities.

Supplier quality management programs work with packaging suppliers to improve material quality and consistency through shared standards and performance feedback.

Technology and Process Enhancement

Evaluate and implement new technologies that can improve detection capabilities, reduce manual errors, and increase inspection efficiency. Automated systems often provide more consistent results than manual inspection.

Process optimization involves regularly reviewing and refining quality control procedures based on performance data and industry best practices. This ensures your system remains effective and efficient.

Benchmarking compares your performance against industry standards and best practices to identify areas for enhancement. This external perspective reveals improvement opportunities that internal analysis might miss.

| Improvement Area | Measurement Method | Target Performance | Review Frequency |

|---|---|---|---|

| Defect Rate | Statistical analysis | <2% major defects | Monthly |

| Customer Complaints | Complaint tracking | <0.5% of shipments | Weekly |

| Inspection Efficiency | Time studies | <5 min per batch | Quarterly |

Summary

Creating a comprehensive quality control checklist requires systematic planning, clear standards, and consistent execution. Focus on physical integrity, material quality, labeling accuracy, sealing performance, and regulatory compliance for complete coverage. Implement strategic checkpoints throughout production, train your team thoroughly, and maintain detailed documentation for continuous improvement. Your quality control system protects brand reputation, ensures customer satisfaction, and reduces costly returns while supporting regulatory compliance.

At Acreet, we understand that quality control is the foundation of successful packaging operations. Our experienced team has developed comprehensive quality systems that meet international standards and customer requirements. We can help you establish effective quality control procedures, provide training for your team, and ensure your custom packaging meets the highest quality standards. Contact us today to discuss how we can support your quality goals and help you build a robust quality control system that protects your brand and satisfies your customers.