Shipping fragile items like glass or ceramics can be nerve-wracking. One wrong move during transit, and your precious products could arrive as expensive broken pieces. Whether you’re a business owner shipping delicate glassware or a retailer handling ceramic collections, the fear of damage claims keeps you up at night.

Custom packaging for fragile items requires a multi-layered approach combining shock-absorbing materials, secure compartmentalization, and reinforced outer protection. The key is creating a snug, cushioned environment that eliminates movement while distributing impact forces away from vulnerable areas.

But there’s much more to effective fragile packaging than just adding bubble wrap. Let’s explore the professional techniques and materials that ensure your delicate items arrive safely every time.

Table of Contents

ToggleWhat Makes Glass and Ceramics So Challenging to Package?

Understanding why glass and ceramics pose unique packaging challenges helps you design better protection systems for your products.

Glass and ceramics are challenging to package because they exhibit high hardness but low fracture toughness, making them prone to catastrophic failure when subjected to stress beyond their limits. Unlike metals that can deform and recover, these materials fail completely when cracked.

Unlike other materials, glass and ceramics have several critical vulnerabilities:

Brittleness and Crack Propagation

Glass and ceramics can shatter from relatively low-force impacts due to their inherent brittleness. Even small surface defects can propagate into complete failures under stress, making surface protection crucial.

Shock Sensitivity

These materials are particularly susceptible to impact damage. The shock from dropping or rough handling can cause immediate failure or create stress fractures that lead to delayed breakage.

Irregular Geometries and Vulnerable Points

Items like teapots, vases, and decorative pieces have protruding parts such as handles, spouts, or decorative elements that are especially vulnerable to damage during transport.

Temperature Sensitivity

Thermal expansion differences can cause cracking during climate changes. Glass and ceramics expand and contract at different rates, creating internal stress that can lead to failure.

| Challenge | Impact Level | Primary Concern |

|---|---|---|

| Brittleness | Critical | Catastrophic failure from minor impacts |

| Shock Sensitivity | Critical | Immediate breakage from drops |

| Irregular Shapes | High | Vulnerable protruding parts |

| Temperature Changes | Medium | Thermal stress cracking |

What Are the Essential Materials for Fragile Item Packaging?

Selecting the right materials forms the foundation of successful fragile packaging design, with each material serving specific protective functions.

Essential materials include polyurethane and polyethylene foams for shock absorption, double-wall corrugated boxes for structural strength, and specialized materials like Plastazote foam and EVA foam sheets for custom applications. Advanced options include foam-in-place technology and air column systems.

Primary Cushioning Materials

Foam Solutions

- Polyurethane (PU) foam: Provides excellent shock absorption with superior compression resistance

- Polyethylene (PE) foam: Offers good moisture resistance and is ideal for items sensitive to humidity

- Expanded polystyrene (EPS) beads: Ultra-lightweight option perfect for filling voids in packaging boxes

Advanced Protective Materials

- Plastazote foam: Closed-cell polyethylene foam that’s incredibly durable yet flexible, with high impact resistance, odorless properties, and low water absorption

- EVA foam sheets: Known for outstanding shock resistance and impact absorption, more durable than PE foam and can be CNC-cut for custom shapes

Specialized Protection Systems

- Foam-in-place technology: Liquid foam that expands and solidifies around items, creating perfect custom fits for unusually shaped pieces

- Shockproof air columns: Made from HDPE, these create custom-fit protection around irregular shapes and can be wrapped around vulnerable areas

Corrugated bubble wrap combines cushioning with structural support, making it ideal for flat glass pieces like mirrors, while biodegradable bubble wrap provides similar protection while supporting sustainability goals.

How Do You Create Custom Inserts for Different Fragile Items?

Custom inserts are the heart of professional fragile packaging, ensuring each item has its own protective chamber with precise fit and maximum protection.

Create custom inserts using die-cutting for standardized products, molded foam for highest protection levels, and laser-cutting technology for rapid prototyping. Modern manufacturing uses CAD software for precise design and CNC cutting for custom shapes.

Design Approaches

Die-Cut Inserts

Foam is precisely cut to fit specific glass items, ensuring tight security and minimal movement during transit. This method works exceptionally well for standardized products like bottles, jars, or recurring product lines.

Custom Molded Foam

While more expensive initially, molded foam inserts provide the highest level of protection by matching the exact shape of the item. These are ideal for high-value or uniquely shaped pieces where maximum protection justifies the cost.

Laser-Cut Precision

Modern manufacturing uses laser cutting technology to create precise foam inserts from digital designs. This approach allows for rapid prototyping, customization, and consistent quality across production runs.

Material Selection for Custom Inserts

Molded Pulp

Made from recycled paper, molded pulp can be shaped to exact product specifications while providing excellent shock absorption and environmental benefits. It’s 100% biodegradable and supports circular economy principles.

U-Shaped Foam Profiles

Specifically designed for glass protection, these expanded polyethylene profiles feature elastic memory that makes them excellent shock absorbers for vulnerable edges and corners.

| Insert Type | Best Application | Protection Level | Cost Factor |

|---|---|---|---|

| Die-cut foam | Standardized items | High | Low-Medium |

| Molded foam | Unique shapes | Highest | High |

| Laser-cut | Prototypes/custom | High | Medium |

| Molded pulp | Eco-friendly needs | High | Medium |

What’s the Optimal Box Structure for Fragile Items?

The outer box structure determines how well your internal protection system performs under real-world shipping conditions and stacking pressures.

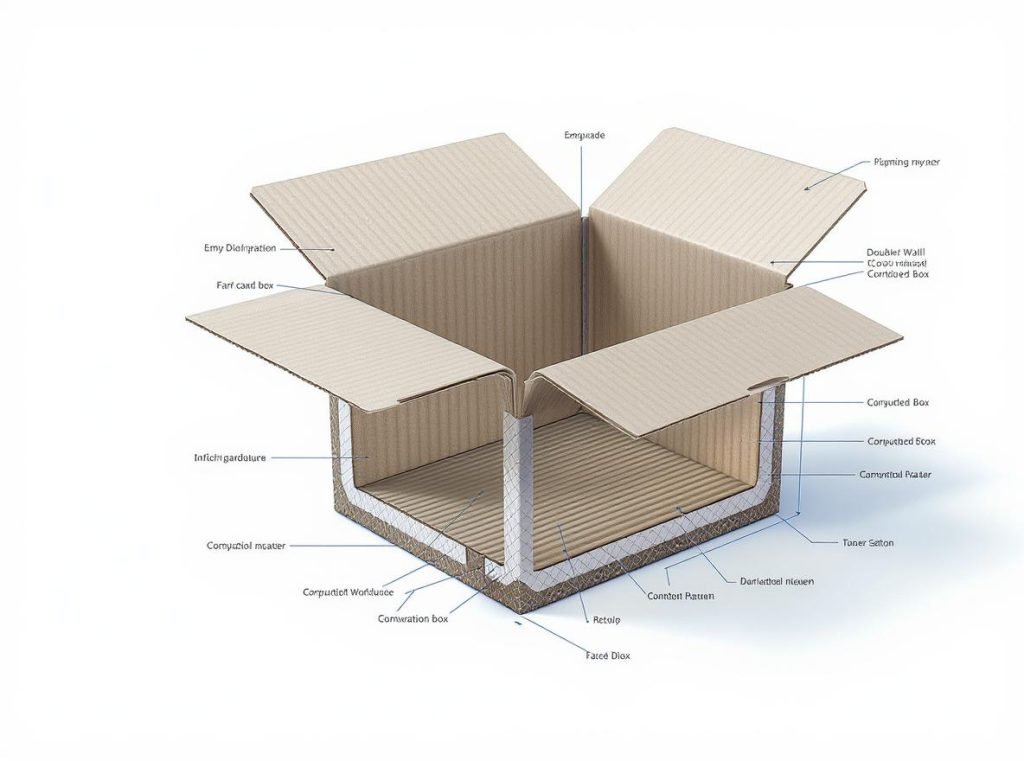

Optimal box structure requires double-wall corrugated boxes with ECT strength ratings of 48 or higher, featuring five-ply construction with two layers of fluting between three layers of liner board. Boxes should allow 3 inches of cushioning on all sides.

Double-Wall Construction Benefits

Double-wall corrugated boxes are essential for fragile items, providing significantly increased strength compared to single-wall alternatives. The five-ply construction offers better crush resistance for stacking during transport and enhanced insulation properties.

Box Sizing Principles

The industry standard requires 3 inches of cushioning on all sides of the item. This ensures adequate protection while preventing excessive movement. Boxes should be only slightly larger than necessary to minimize material waste and shipping costs.

Structural Reinforcement Techniques

Bottom reinforcement is critical for fragile items. Use the “H” taping method – tape down the middle seam and on each edge to create maximum structural integrity. For heavier items exceeding 50 kilograms, consider wooden or metal reinforcement.

Weight and Size Considerations

Right-sizing boxes to closely match product dimensions minimizes material waste and shipping costs. Oversized boxes require more cushioning material and cost significantly more to ship.

How Do You Handle Irregular Shapes and Protruding Parts?

Irregular shapes require creative solutions to ensure complete protection without over-packaging, focusing on vulnerable areas that are most likely to suffer damage.

Handle irregular shapes by identifying vulnerable areas like glass stems and ceramic handles, covering protrusions with corrugated cardboard scraps, using mesh sleeves for flexible protection, and employing paperboard packaging for oddly shaped items.

Vulnerable Area Protection

Identify weak points such as glass stems, ceramic handles, or protruding decorative elements. These areas require additional padding and support to prevent breakage during handling and transport.

Protrusion Management

Cover protrusions with corrugated cardboard scraps and tape them in place. This creates a more uniform shape for easier packaging and reduces the risk of puncturing protective materials.

Flexible Protection Solutions

For items like teapot spouts or decorative elements, use mesh sleeves to provide flexible protection that conforms to the shape while allowing some movement without damage.

Custom Void Fill Strategies

Use crinkle paper, packing peanuts, or custom-cut foams to eliminate empty spaces that could allow movement. The key is ensuring products cannot shift during transport, which could cause impact damage.

What Are the Best Practices for Multi-Item Packaging?

Packaging multiple fragile items together requires careful planning to prevent damage from inter-item contact while optimizing space and materials.

Best practices include individual wrapping of each item with minimum 3-inch thickness of air-cellular cushioning, using corrugated dividers between items, placing heavier items at the bottom, and implementing double-boxing methods for extremely fragile pieces.

Individual Item Protection

Each fragile item must be wrapped separately to prevent contact damage. Use minimum 3-inch thickness of air-cellular cushioning material around each piece, ensuring complete coverage of all surfaces.

Separation and Divider Systems

Insert corrugated dividers between items to prevent unwanted contact. This is particularly important when shipping multiple pieces in a single container, as even minor contact can cause chipping or cracking.

Weight Distribution Strategy

Place heavier items at the bottom and lighter items on top. This approach prevents crushing and helps maintain the package’s center of gravity, reducing the risk of tipping during transport.

Stacking Considerations for Similar Items

For items like plates or flat glass pieces, place paper and corrugated cardboard between each piece, then wrap the entire stack in bubble wrap. This method provides individual protection while maintaining stack stability.

Double-Boxing for Maximum Protection

For extremely fragile items, use a smaller box inside a larger one with 3 inches of cushioning around the inner box. This provides an additional layer of protection if the outer box is damaged during handling.

How Do You Test Your Packaging Design Effectiveness?

Testing validates your packaging design and identifies potential failure points before products reach customers, ensuring reliability and cost-effectiveness.

Test packaging effectiveness through standardized drop tests from 0.5 to 1.5 meters depending on weight, vibration testing to simulate transportation conditions, compression testing for stacking loads, and following ISTA or ASTM D4169 standards for certification.

Standard Testing Protocols

Drop Testing Standards

Simulate real-world handling by dropping packages from heights of 0.5 to 1.5 meters depending on weight. Tests should include drops on corners, edges, and faces in specific sequences to identify weak points.

Vibration Testing

Use vibration tables to simulate transportation conditions including aircraft, truck, and rail transport. This testing reveals how packaging performs under sustained movement and helps identify resonance frequencies that could cause damage.

Compression Testing

Assess the package’s ability to withstand stacking loads during warehouse storage and transport. This ensures packages maintain structural integrity under normal storage conditions.

Industry Standards and Certifications

ISTA Standards

Provide detailed, step-by-step testing procedures that must be strictly followed. ISTA testing can reduce product loss and breakage by up to 30% when properly implemented.

ASTM D4169

Offers flexible testing parameters where operators can adjust levels, sequences, and orientations based on specific needs and shipping conditions.

Performance Metrics

Packages should show no functional or mechanical failures after testing. Products must arrive intact with no damage to packaging or contents, and detailed documentation including photographs and test results should be maintained.

What Are Cost-Effective Solutions for Small Businesses?

Small businesses need effective fragile packaging without the high costs of custom tooling and large minimum orders, focusing on scalable solutions.

Cost-effective solutions include using corrugated boxes available at low cost in bulk, kraft paper for economical cushioning, recycled materials for void fill, right-sizing boxes to minimize waste, and developing standard packaging recipes for common products.

Budget-Friendly Materials

Corrugated Boxes

Available at low cost when ordered in bulk, providing excellent protection-to-cost ratio. These boxes can be customized with branding without significant cost increases.

Kraft Paper Solutions

One of the most cost-effective cushioning materials, kraft paper can be used for void fill and provides good protection while being environmentally friendly and recyclable.

Recycled Materials

Use recycled paper, newspaper, and cardboard scraps for cushioning and void fill. These materials are often free or very low-cost and support sustainability goals.

Efficient Packaging Strategies

Right-Sizing Approach

Use boxes that closely match product dimensions to minimize material waste and shipping costs. This approach reduces cushioning requirements and shipping expenses.

Bulk Purchasing Benefits

Order packaging materials in bulk to achieve better pricing. Consider partnering with other small businesses to achieve volume discounts and share minimum order requirements.

Standardization Programs

Develop standard packaging recipes for common products to streamline operations and reduce material variety. This approach improves efficiency and reduces inventory complexity.

| Strategy | Cost Savings | Implementation Difficulty | Effectiveness |

|---|---|---|---|

| Bulk purchasing | High | Low | High |

| Right-sizing | Medium | Low | High |

| Recycled materials | High | Low | Medium |

| Standardization | Medium | Medium | High |

How Do You Ensure Environmental Sustainability in Fragile Packaging?

Modern businesses must balance protection requirements with environmental responsibility, choosing materials and methods that minimize ecological impact.

Ensure sustainability by using molded pulp made from recycled paper, biodegradable packing peanuts from cornstarch, recyclable foam with minimum 65% recycled content, and designing packaging for reuse and recycling to support circular economy principles.

Eco-Friendly Material Options

Molded Pulp Solutions

Made from recycled paper and 100% biodegradable, molded pulp provides excellent cushioning while supporting circular economy principles. It can be molded to exact product specifications for optimal protection.

Biodegradable Alternatives

Use biodegradable packing peanuts made from cornstarch or other plant materials. These dissolve in water and leave no toxic residue, making disposal environmentally safe.

Recyclable Foam Systems

Modern polyethylene foams contain minimum 65% recycled content and can be recycled back into the supply stream, reducing the need for virgin materials.

Sustainable Design Practices

Material Optimization

CAD software can help minimize material usage through precise design and optimization. This reduces waste while maintaining protection effectiveness and lowering overall environmental impact.

Circular Economy Integration

Design packaging for reuse and recycling to keep materials in circulation longer. This approach reduces the need for virgin materials and supports sustainable business practices.

Life Cycle Assessment

Consider the complete environmental impact from production through disposal when selecting materials. This holistic approach ensures truly sustainable packaging solutions.

What Technology Can Improve Fragile Packaging Design?

Modern technology offers tools to optimize packaging design, reduce trial-and-error approaches, and improve overall effectiveness and efficiency.

Technology improvements include CAD software for precise design with real-time optimization, 3D printing for rapid prototyping, packaging simulation software for virtual testing, and AI-powered systems for automated analysis and quality control.

Advanced Design Software

Computer-Aided Design (CAD)

Modern CAD systems enable precise packaging design with real-time optimization capabilities. These tools can simulate structural integrity and material usage before production, reducing development time and costs.

3D Modeling and Visualization

Software like Autodesk Fusion 360 and SolidWorks allow designers to create detailed 3D models and run simulations. This enables testing of packaging performance before creating physical prototypes.

Packaging-Specific Tools

Software like Packmage and Arden Software are designed specifically for packaging design, offering industry-specific features and templates that streamline the design process.

Automation and Quality Control

Machine Vision Integration

Combining CAD with machine vision technology provides automated quality control and real-time feedback for packaging optimization, ensuring consistent quality across production runs.

AI-Powered Analysis

AI systems can analyze packaging designs and suggest optimizations for material usage and protection effectiveness, reducing human error and improving overall performance.

Production Integration

CAD systems can connect directly to manufacturing equipment, including 3D printing and laser cutting systems, streamlining the transition from design to production.

Summary

Designing custom packaging for fragile items requires a systematic approach combining advanced materials, precise engineering, and thorough testing. Key elements include double-wall corrugated boxes with ECT ratings of 48 or higher, specialized foam inserts using materials like Plastazote or EVA foam, and maintaining 3-inch cushioning buffers on all sides. Professional testing following ISTA or ASTM standards ensures reliability and can reduce breakage by up to 30%.

Ready to protect your fragile products with professional custom packaging solutions? Contact Acreet today for expert consultation on advanced packaging design and custom box manufacturing. Our engineering team specializes in creating cost-effective protection systems that meet international shipping standards while optimizing your packaging costs and sustainability goals.