Liquid products face unique packaging challenges that can devastate your business overnight. From costly leakage disasters during shipping to regulatory compliance headaches, improper liquid packaging costs companies thousands in damaged goods, returned shipments, and lost customer trust.

The key to successful liquid packaging lies in choosing the right container materials, implementing professional sealing techniques, and following strict shipping regulations. Professional liquid packaging combines leak-proof primary containers, protective secondary packaging, and compliance with hazardous material guidelines to ensure products arrive safely while maintaining brand appeal on retail shelves.

Let’s explore the complete guide to liquid packaging that protects your products and profits.

Table of Contents

ToggleWhat Are the Main Types of Liquid Packaging Containers?

Understanding your container options is the foundation of effective liquid packaging strategy for wholesale and retail success.

The seven primary liquid container types are plastic bottles, glass bottles, flexible pouches, metal containers, IBCs, flexitanks, and industrial drums. Each offers distinct advantages for different liquid types, shipping requirements, and retail presentation needs.

Plastic Bottles and Containers

Plastic containers dominate liquid packaging due to their versatility and cost-effectiveness for wholesale operations.

Popular plastic materials and their applications:

- HDPE (High-Density Polyethylene): Ideal for cleaners, chemicals, and milk jugs

- PET (Polyethylene Terephthalate): Perfect for beverages, fruit juices, and vegetable oils

- PP (Polypropylene): Excellent for acetone, acids, alcohols, and first aid liquids

- LDPE (Low-Density Polyethylene): Suitable for squeeze bottles and flexible applications

Chemical compatibility is crucial – PE containers resist alcohols and acids but avoid using them for oils, gasoline, or aromatic compounds.

Glass Bottles and Jars

Glass remains the premium choice for luxury liquid products, especially in food, pharmaceutical, and cosmetic markets.

Glass advantages for wholesale distribution:

- Complete barrier protection against contamination

- Preserves product freshness and flavor indefinitely

- Premium brand perception increases retail value

- Fully recyclable and environmentally sustainable

- Chemical inertness prevents product reactions

However, glass requires specialized protective packaging due to fragility and 2-3 times higher material costs compared to plastic alternatives.

Flexible Pouches and Stand-Up Bags

Modern flexible packaging offers innovative solutions with growing market acceptance and superior space efficiency.

| Feature | Advantage | Wholesale Benefit |

|---|---|---|

| Material Efficiency | Uses 85% less packaging material | Reduced material costs |

| Storage Density | 20-25% better space utilization | Lower warehousing expenses |

| Barrier Properties | Multi-layer films (PET/PA/PE, PET/AL/PE) | Extended shelf life protection |

| Dispensing Options | Various spout and closure types | Consumer convenience appeal |

Industrial and Bulk Liquid Containers

For large-volume liquid distribution, specialized containers offer significant advantages.

Flexitanks revolutionize bulk liquid transport by allowing up to 31% more capacity than traditional containers, with volumes ranging from 10,000 to 24,000 liters. Intermediate Bulk Containers (IBCs) provide stackable, reusable functionality perfect for wholesale chemical distribution. Industrial drums remain the standard for hazardous liquids, offering secure containment and standardized handling protocols.

How Do You Choose the Right Packaging Materials for Different Liquids?

Material compatibility directly impacts product safety, shelf life, and shipping success for your wholesale operations.

Match packaging materials to liquid properties by conducting chemical compatibility testing, assessing barrier requirements, evaluating temperature sensitivity, and considering viscosity factors. Chemical reactivity testing is mandatory to prevent container degradation and product contamination.

Chemical Compatibility Assessment

Before selecting containers, conduct thorough compatibility testing with your specific liquid formulation.

Critical compatibility testing includes:

- pH level tolerance (acidic vs. alkaline products)

- Alcohol content percentage effects

- Essential oil concentration impacts

- Chemical additives and preservative reactions

- Long-term stability under storage conditions

Polyethylene (PE) containers show excellent resistance to alcohols, ammonia, and acids, but are not recommended for oils, gasoline, or aromatic compounds. Polypropylene (PP) offers broad chemical compatibility with acetone, acids, and alcohols.

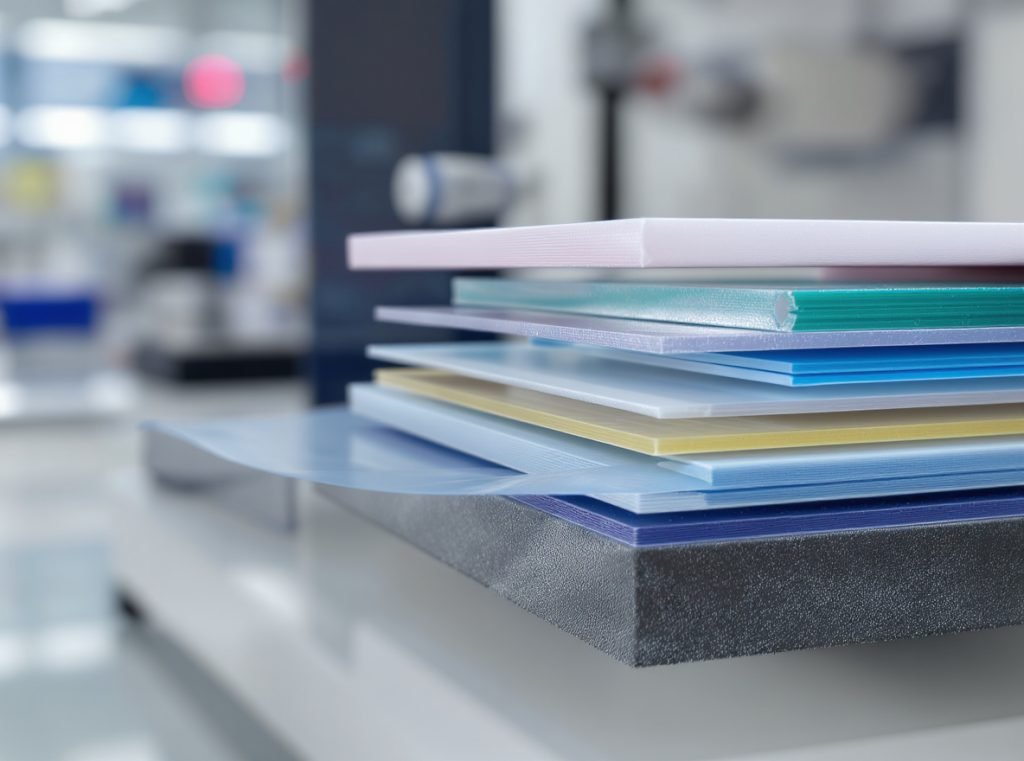

Advanced Barrier Protection Systems

Different liquids require specific barrier protections to maintain quality during extended storage and international shipping.

Essential barrier technologies include:

Multi-layer barrier films combining PET/PA/PE or PET/AL/PE structures provide enhanced protection against:

- Oxygen penetration preventing oxidation in food products

- Moisture barrier protection for hygroscopic liquids

- Light barrier shielding for UV-sensitive formulations

- Aroma barrier maintenance for fragranced products

Glass containers offer the most inert solution with complete barrier protection, while specialized plastic films deliver targeted barrier properties at significantly lower costs.

Temperature and Environmental Considerations

Professional liquid packaging must withstand extreme temperature variations during international shipping and storage.

| Temperature Challenge | Packaging Solution | Material Recommendation |

|---|---|---|

| Cold Chain Products | Insulated packaging systems | Flexible materials resistant to cracking |

| Heat-Sensitive Liquids | UV-blocking materials | Amber glass or UV-resistant plastics |

| Freeze-Thaw Cycles | Flexible container materials | LDPE or specialized flexible films |

| Hot-Fill Applications | Heat-resistant containers | PP or specialized high-temp plastics |

What Are the Essential Shipping Requirements for Liquid Products?

Shipping compliance protects your business from legal liability and ensures safe product delivery across international markets.

Liquid shipping requires proper hazard classification, UN-specification packaging for dangerous goods, comprehensive documentation, and carrier-specific compliance. U.S. Department of Transportation Title 49 governs domestic transport, while IMDG Code and ICAO/IATA standards regulate international shipping.

Hazardous vs. Non-Hazardous Classification

Proper classification determines packaging specifications and shipping requirements for your liquid products.

Non-hazardous liquids include:

- Water-based cosmetics and lotions

- Food products like sauces and non-alcoholic beverages

- Pharmaceutical solutions (non-flammable)

- Cleaning products without dangerous chemicals

Hazardous liquids requiring specialized handling:

- Class 3: Flammable liquids (alcohol-based products, perfumes)

- Class 8: Corrosive substances (strong acids, bases)

- Compressed liquid gases

- Toxic liquid chemicals

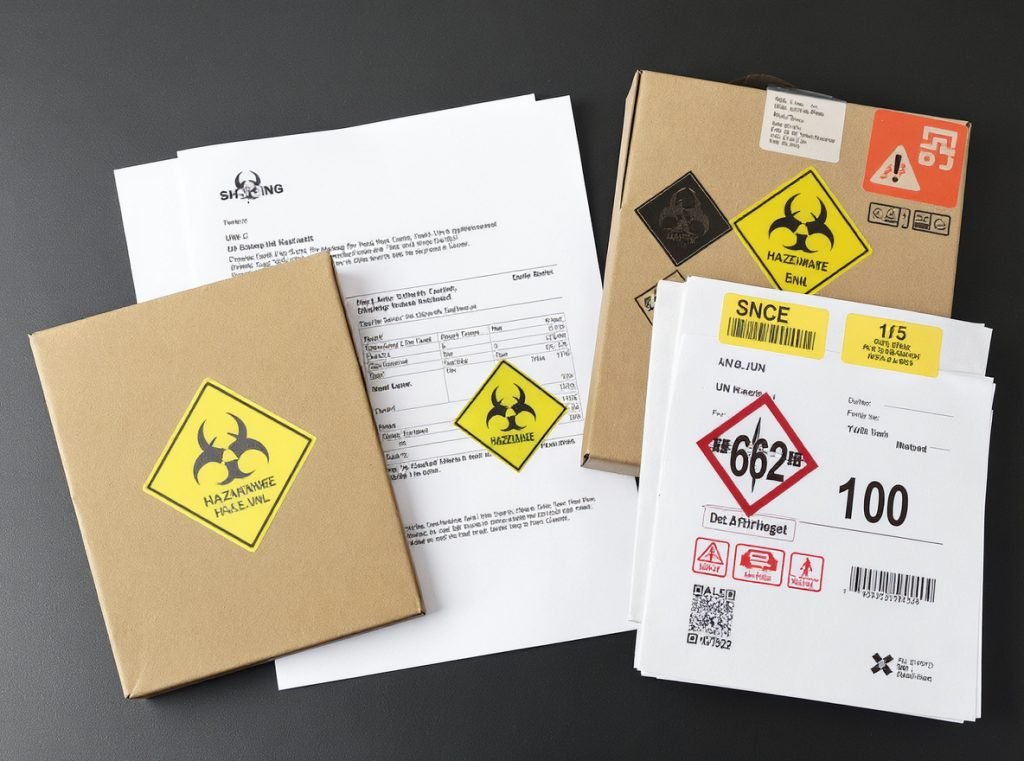

International Shipping Documentation

Comprehensive documentation ensures smooth customs clearance and regulatory compliance.

Required shipping documentation includes:

- Safety Data Sheets (SDS) mandatory for hazardous materials

- Dangerous goods declarations with proper classifications

- Country-specific import/export permits and certifications

- Carrier-specific liquid shipping forms and manifests

- Emergency contact information and response procedures

Proper hazard labeling prevents handling mistakes and expedites delivery processing through customs.

UN-Specification Packaging Requirements

Hazardous liquids must use UN-specification packaging that meets rigorous performance standards.

UN packaging specifications require:

- Drop test certification for impact resistance

- Pressure testing for seal integrity

- Temperature cycling validation

- Vibration resistance verification

- Stack load testing for warehouse storage

How Do You Prevent Leaks and Damage During Transit?

Leak prevention requires multiple protection layers and professional packaging techniques to avoid costly damage.

Effective leak prevention combines primary container sealing, secondary containment systems, cushioning materials, and proper handling protocols. Studies show liquid leaks can affect 2-9 surrounding packages and require up to 30 minutes cleanup time, making prevention critical.

Advanced Sealing Technologies

Professional sealing ensures reliable leak prevention throughout the supply chain.

Heat sealing uses controlled temperature and pressure to create airtight bonds on flexible packaging. Ultrasonic sealing provides precise, clean seals even with liquid residue present on package surfaces. Tamper-evident capping systems ensure proper torque application and provide visual evidence of tampering.

Critical sealing protocols include:

- Torque specifications for threaded caps (typically 15-25 inch-pounds)

- Heat sealing temperature and dwell time optimization

- Crimp sealing force calibration for metal containers

- Induction sealing for enhanced tamper evidence

The dry chamber flexible package test is the most reliable method for detecting microscopic leaks in liquid-containing packages.

Secondary Containment Systems

Secondary packaging provides crucial backup protection when primary containers fail.

Professional containment strategies include:

- Sealed polyethylene bags around each primary container

- Absorbent padding materials capable of containing 100% liquid volume

- Rigid outer packaging boxes with cushioning compartments

- Compartmentalized packaging preventing cross-contamination

The containment system must handle complete primary container failure while protecting surrounding shipments.

Environmental Protection During Transport

Temperature fluctuations, pressure changes, and vibration during transport stress packaging systems.

| Transport Stress | Impact on Packaging | Protection Strategy |

|---|---|---|

| Temperature Variation | Container expansion/contraction | Flexible sealing materials |

| Atmospheric Pressure | Vacuum/pressure on containers | Vented secondary packaging |

| Vibration/Shock | Mechanical stress on seals | Multi-layer cushioning systems |

| Humidity Changes | Condensation issues | Moisture barrier protection |

What Retail Packaging Considerations Affect Liquid Products?

Retail success requires packaging that protects products while maximizing shelf appeal and consumer convenience.

Retail liquid packaging must balance functional performance with visual impact, convenience features, and cost efficiency. Visual hierarchy, brand storytelling, and distinctive shapes drive consumer purchasing decisions while convenience features signal product quality.

Shelf Presentation Optimization

Liquid products compete intensively for consumer attention in crowded retail environments.

Visual hierarchy guides consumer attention through strategic design elements:

- Eye-level positioning receives 35% more consumer attention

- Clear or translucent containers showcase product quality

- Distinctive shapes create instant brand recognition

- Strategic color placement draws attention from 3+ feet away

Brand storytelling through packaging design should reflect target audience preferences and brand values, with premium glass containers commanding 20-30% higher retail prices than plastic alternatives.

Consumer Convenience Engineering

Modern consumers prioritize packaging functionality that enhances product usability.

Essential convenience features include:

- Pump dispensers for controlled portions in lotions and soaps

- Flip-top caps enabling easy one-handed operation

- Measuring systems built into container lids for accurate dosing

- Resealable closures maintaining product freshness for multi-use items

- Ergonomic grips preventing slipping in wet-use applications

Easy-open mechanisms and lightweight materials signal thoughtfulness toward consumer needs, directly influencing purchasing decisions.

Size and Portion Strategy

Right-sizing liquid packaging affects both manufacturing costs and consumer appeal across different market segments.

Optimization considerations include:

- Usage frequency and typical consumption rates

- Consumer storage space limitations

- Price point positioning within product category

- Case pack efficiency for retail distribution

- Regulatory volume requirements for specific categories

Travel-size versions often command 200-300% premium pricing per unit volume while building brand loyalty for full-size products.

How Do Regulations Impact Liquid Packaging Design?

Regulatory compliance shapes every aspect of liquid packaging from material selection to final labeling requirements.

Liquid packaging regulations encompass food safety standards, chemical handling protocols, environmental impact requirements, and consumer protection mandates. FDA guidelines for food contact materials and EU Regulation 10/2011 establish strict testing protocols and compositional requirements.

Food and Beverage Compliance

Food contact materials must meet rigorous safety standards preventing contamination and ensuring consumer safety.

FDA guidelines mandate specific requirements:

- Migration testing protocols for chemical transfer assessment

- Compatibility testing demonstrating no adverse reactions

- Good Manufacturing Practice (GMP) compliance for production

- Nutritional labeling accuracy and placement requirements

- Allergen declaration and cross-contamination prevention

Chemical compatibility testing is mandatory to demonstrate packaging materials won’t react with liquid contents throughout the product’s shelf life.

International Regulatory Complexity

Global liquid distribution requires understanding diverse regulatory environments across target markets.

EU regulations including Regulation 10/2011 establish:

- Compositional requirements for plastic food contact materials

- Migration limits for specific substances

- Declaration of compliance protocols

- Traceability requirements throughout supply chains

Pharmaceutical packaging must meet stringent Good Manufacturing Practice requirements covering material specifications, manufacturing processes, and comprehensive quality controls.

Environmental and Sustainability Mandates

Growing environmental regulations significantly impact packaging material choices and disposal methods.

Current regulatory trends include:

- Recycled content minimums (15% for beverage bottles in New Jersey)

- Extended producer responsibility programs

- Single-use plastic restrictions in multiple jurisdictions

- Carbon footprint reporting requirements for large manufacturers

- Biodegradable material incentives and tax advantages

Plan ahead for regulatory changes by incorporating sustainability requirements into packaging strategies now.

What Are the Cost Factors in Liquid Packaging?

Understanding total packaging costs enables strategic optimization of your liquid packaging investment across wholesale operations.

Liquid packaging costs include materials, manufacturing, filling equipment, transportation, storage, and regulatory compliance. Hidden costs like damage rates, returns, and space utilization significantly impact total cost of ownership.

Material and Manufacturing Economics

Direct packaging costs vary substantially based on material choices and production volumes for wholesale operations.

Volume pricing creates significant economies of scale:

- High-volume orders (100,000+ units) reduce per-unit costs by 25-40%

- Standardized container sizes across product lines minimize tooling costs

- Automated filling line compatibility increases throughput by 30-40%

- Lightweight packaging materials reduce shipping expenses by 15-20%

| Container Type | Material Cost | Durability | Consumer Appeal | Best Application |

|---|---|---|---|---|

| Plastic Bottle | Low | High | Medium | Mass market products |

| Glass Bottle | High (2-3x plastic) | Medium | High | Premium products |

| Flexible Pouch | Very Low | Medium | Medium | Cost-sensitive markets |

| Metal Container | Medium | High | High | Carbonated beverages |

Operational Efficiency Impact

Packaging design affects operational costs throughout your entire supply chain and distribution network.

Space utilization dramatically affects warehousing costs:

- Stick packs deliver 20-25% better space efficiency than equivalent sachets

- Stackable containers optimize warehouse density

- Flexible packaging reduces storage volume by up to 85%

- Nested containers minimize shipping cube utilization

Equipment investment considerations:

- Sachet machines require 15-20% lower initial investment

- Stick pack equipment delivers 30-40% higher throughput rates

- Multi-format filling lines provide production flexibility

- Automated systems reduce labor costs by 40-60%

Total Cost Ownership Analysis

Complete cost analysis reveals the true value proposition of different packaging options for wholesale operations.

Transportation cost factors:

- Package weight directly impacts shipping expenses

- Dimensional weight pricing penalizes inefficient shapes

- Damage rates vary significantly by packaging type

- International shipping adds complexity and costs

Hidden cost considerations:

- Damage and return processing expenses

- Regulatory compliance and documentation costs

- Quality control and inspection requirements

- Inventory carrying costs and storage efficiency

How Do You Work with Packaging Suppliers for Custom Solutions?

Strategic supplier partnerships deliver packaging solutions that meet your specific wholesale distribution needs.

Successful liquid packaging projects require detailed specifications, comprehensive prototype testing, regulatory coordination, and robust quality assurance programs. Choose suppliers with proven liquid packaging expertise and manufacturing capabilities matching your volume requirements.

Supplier Evaluation Criteria

Selecting the right packaging partner requires assessment of multiple capabilities beyond basic pricing considerations.

Essential supplier qualifications include:

- Liquid packaging specialization and industry experience

- Vertical integration capabilities for quality control

- Advanced sealing technologies and barrier film expertise

- Regulatory compliance knowledge across target markets

- Global manufacturing and distribution capabilities

Technical capabilities should encompass compatibility testing, custom barrier film development, and specialized sealing technologies for leak-proof packaging.

Specification Development Process

Detailed specifications ensure suppliers understand your exact requirements and can deliver appropriate solutions.

Critical specification elements include:

- Liquid properties: pH levels, viscosity, chemical composition

- Volume requirements: Fill levels, headspace specifications

- Barrier properties: Oxygen, moisture, light protection needs

- Closure systems: Dispensing mechanisms, tamper evidence

- Regulatory compliance: FDA, EU, international requirements

- Sustainability goals: Recycled content, biodegradability

Provide representative liquid samples to suppliers for thorough compatibility testing and prototype development.

Quality Assurance and Partnership Management

Reliable suppliers provide comprehensive quality assurance and ongoing technical support throughout product lifecycles.

Look for suppliers offering:

- Statistical process control with regular performance monitoring

- Comprehensive testing protocols including drop, leak, and stability testing

- Technical support for filling line integration and troubleshooting

- Regulatory update notifications and compliance assistance

- Continuous improvement initiatives and cost optimization programs

Partnership evaluation should consider production flexibility, quality certifications, global reach, and long-term innovation capabilities for sustainable business growth.

Customization and Innovation Support

Leading packaging suppliers provide comprehensive customization capabilities and innovation support for competitive advantage.

Advanced customization options include:

- Various container designs, sizes, and material combinations

- Specialized barrier coatings and multi-layer constructions

- Custom dispensing systems and closure technologies

- Brand-specific decoration and labeling solutions

- Sustainable packaging alternatives and circular economy solutions

The right supplier becomes a strategic partner in product development, helping optimize packaging performance while managing costs and ensuring compliance across global markets.

Summary

Successful liquid packaging requires careful integration of container selection, material compatibility, shipping compliance, and retail optimization strategies. Professional packaging solutions balance product protection, regulatory requirements, consumer appeal, and operational efficiency. Partner with experienced suppliers who understand liquid packaging complexities and can provide comprehensive testing, quality assurance, and ongoing technical support.

Ready to develop the perfect packaging solution for your liquid products? Contact Acreet today for expert consultation on custom liquid packaging design. Our team specializes in creating comprehensive packaging solutions that protect your products, ensure regulatory compliance, and enhance your brand’s market appeal. Send us your liquid packaging requirements for a personalized recommendation and competitive wholesale pricing quote.