Product damage during shipping is every business owner’s nightmare. Whether you’re shipping electronics, cosmetics, or food products, damaged goods lead to costly returns, unhappy customers, and damaged brand reputation. With 10% of eCommerce packages arriving damaged and 85 million damaged packages reaching doorsteps annually, custom packaging offers a strategic solution to protect your products throughout their journey.

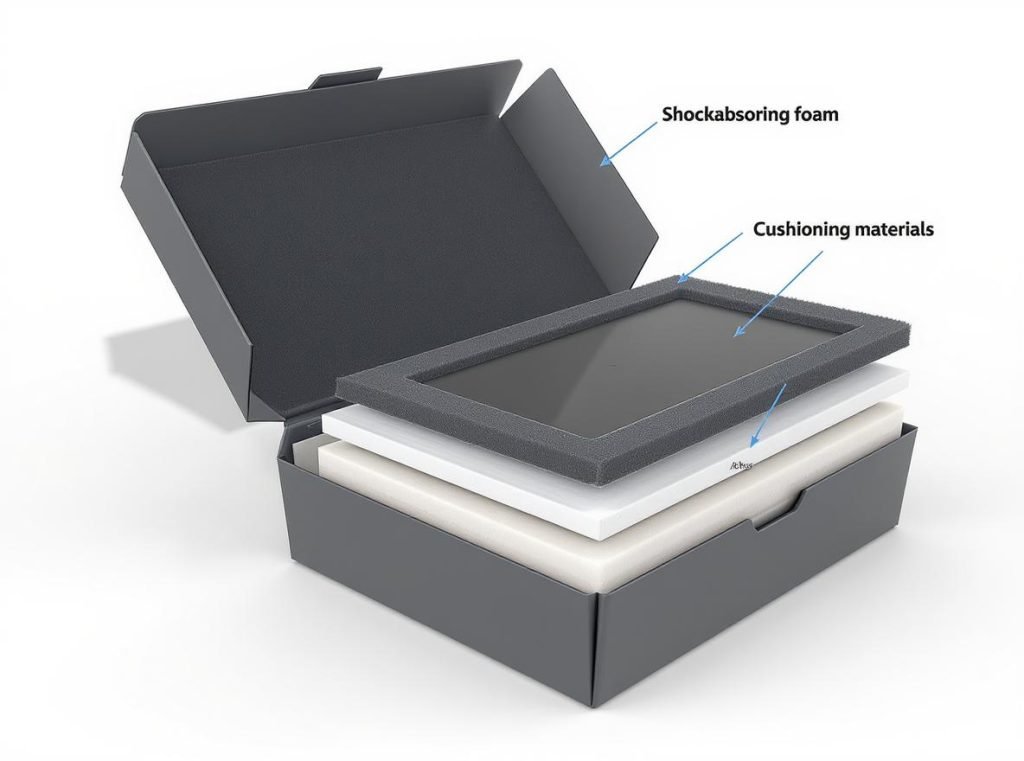

Custom packaging creates a perfect fit protection system specifically designed for your products, reducing movement inside boxes and protecting against external impacts. It utilizes specialized materials and shock-absorbing mechanisms that work together to dissipate forces, preventing the most common causes of shipping damage.

Understanding how custom packaging protects your products can save your business from the $2.92 billion in damaged delivery costs that hit the industry annually while building customer loyalty through consistently safe deliveries.

Table of Contents

ToggleWhat Makes Custom Packaging Different from Standard Shipping Boxes?

Custom packaging goes beyond the one-size-fits-all approach of standard shipping boxes. While generic boxes provide basic protection, they often leave products vulnerable to damage during the shipping process due to poor fit and lack of specialized protection features.

Custom packaging is specifically designed and tailored to meet the unique requirements of a product or brand, providing perfect fit that minimizes movement during transit. Unlike standard packaging that is typically generic and lacks branding elements, custom solutions incorporate product-specific design features and specialized materials.

The fundamental differences create significant protection advantages:

Perfect Product Fit: Custom packaging provides a snug fit that reduces movement inside the box, protecting products from external impacts. The average standard box is 40% too big for its contents, creating unnecessary space that allows products to shift and collide during transit.

Specialized Materials: Custom solutions utilize materials specifically chosen for your product type. Electronics require anti-static foam, while fragile items need shock-absorbing cushioning materials. Standard boxes use generic corrugated cardboard regardless of contents.

Enhanced Protection Features: Custom packaging incorporates additional padding, inserts, reinforced corners, and specialized design features like ventilation holes or transparent lids. These elements work together to create comprehensive protection systems.

Branding Integration: Unlike standard packaging, custom solutions provide branding opportunities with colors, graphics, and logos that strengthen brand identification while maintaining protection effectiveness.

| Feature | Standard Packaging | Custom Packaging |

|---|---|---|

| Fit | Generic sizes, often oversized | Perfect fit, minimal movement |

| Materials | Basic corrugated cardboard | Product-specific protective materials |

| Protection | Basic structural protection | Multi-layer specialized protection |

| Branding | No branding opportunities | Full branding integration |

| Customization | Limited options | Tailored to specific requirements |

How Does Custom Packaging Prevent Common Shipping Damage?

Shipping damage occurs through predictable mechanisms, and custom packaging addresses each vulnerability systematically. Understanding these damage sources helps explain why custom solutions are so effective at prevention.

Custom packaging prevents the most common shipping risks including mishandling during transit, environmental factors, and improper sealing. It addresses these through engineered materials that absorb shocks and vibrations, precise fit that prevents movement, and durable construction that resists tearing and crushing.

Impact and Vibration Protection: Mishandling during transit causes packages to be dropped, crushed, or exposed to rough loading processes. Custom packaging engineered with materials that absorb shocks and vibrations reduces breakage risk significantly.

Cushioned inserts and foam padding protect delicate items like electronics or glassware from impacts. These materials create protective barriers that dissipate impact forces across larger surface areas, preventing concentrated damage points.

Movement Prevention: Products shifting within oversized packaging represents the primary cause of shipping damage. Custom packaging that fits products perfectly prevents unnecessary movement and friction, ensuring items remain secure and stable throughout transit.

Environmental Protection: Custom packaging creates protective barriers against environmental hazards including:

- Moisture-resistant barriers that safeguard against water damage

- Thermal insulation that maintains stable temperature conditions

- Anti-static properties that protect electronic components

- Cushioning that shields against shock, vibration, and temperature fluctuations

Structural Integrity: Custom packaging uses high-quality, durable materials that resist tearing, puncturing, and crushing. Double-wall or triple-wall corrugated cardboard adds additional protection layers for heavier or more fragile items.

What Types of Products Benefit Most from Custom Packaging Protection?

Certain product categories experience the greatest benefits from custom packaging protection due to their inherent vulnerabilities, high value, and specific protection requirements.

Electronics, fragile items, medical devices, and industrial products see the most significant protection benefits from custom packaging. These categories are particularly vulnerable to impact damage, environmental factors, and handling stress that standard packaging cannot adequately address.

Electronics and High-Value Items: Electronics and electronic components are often fragile, high-value, precision-made items that customers rely on arriving damage-free. These products are not only costly but also delicate and susceptible to damage during transit or storage.

Custom packaging for electronics must protect against shock, vibration, moisture, static electricity, and temperature fluctuations. Anti-static foam inserts safely dissipate electrostatic charges while moisture barriers maintain optimal humidity levels.

Fragile Items: Products with fragile components such as screens, sensors, glassware, and ceramics require specialized protection through bespoke packaging solutions. Custom packaging for fragile items:

- Prevents breakage through tailored design

- Uses strong materials chosen to withstand bumps and drops

- Provides extra cushioning like bubble wrap or foam to prevent impact exposure

- Creates individual compartments preventing item-to-item contact

Medical Devices and Pharmaceuticals: These products demand sterile environments and protection against contamination. Custom packaging addresses specific regulatory requirements rather than forcing products to adapt to standardized solutions.

Industrial and Manufacturing Products: Heavy or unusually shaped industrial products benefit from custom packaging that accommodates complex part geometries and provides structural support for repeated handling and stacking.

| Product Category | Primary Vulnerabilities | Custom Protection Solutions |

|---|---|---|

| Electronics | Static, moisture, impact, temperature | Anti-static foam, moisture barriers, thermal insulation |

| Fragile Items | Impact, vibration, breakage | Shock-absorbing materials, individual compartments |

| Medical Devices | Contamination, sterility | Sterile environments, regulatory compliance features |

| Industrial Products | Weight, complex shapes | Structural support, geometric accommodation |

How Much Does Shipping Damage Cost Businesses Without Proper Protection?

The financial impact of shipping damage extends far beyond the immediate cost of replacing damaged products. Current industry statistics reveal the massive scope of this problem affecting businesses worldwide.

Shipping damage costs businesses 0.5% of gross sales annually, with the total cost of damaged deliveries reaching approximately $2.92 billion per year. The true cost includes replacement products, lost customer lifetime value, and hidden operational expenses that compound the financial impact.

Direct Financial Impact: The immediate costs create significant financial burden:

With 85 million damaged packages arriving on doorsteps in the last 12 months, businesses face substantial replacement costs. These expenses include rush shipping for replacements, customer service time, and processing returns.

Warehouse labor costs for processing returns and re-fulfillment add operational expenses. Packaging supplies used twice for original shipments and replacements increase material costs beyond the initial investment.

Customer Lifetime Value Loss: The most expensive part of shipping damage involves lost future business:

57% of consumers would be hesitant to shop with a retailer again if they received a broken or damaged item. In detailed studies, 73% of participants indicated they would be unlikely to purchase from the company again after receiving damaged items.

This customer lifetime value impact represents the most significant long-term cost, as acquiring new customers costs significantly more than retaining existing ones.

Hidden Operational Costs: Less obvious expenses create ongoing financial drain:

- Customer service time spent handling complaints and returns

- Lost profits from original sales that must be replaced

- Potential loss of future orders based on negative experiences

- Brand reputation damage spreading through reviews and social media

Industry-Wide Carrier Impact: Even transportation companies face significant costs, with 39% of carriers asked to pay for container/trailer damage even when not responsible, creating costs surpassing $1.8 billion annually in the U.S.

What Custom Packaging Materials Provide the Best Protection?

Material selection forms the foundation of effective custom packaging protection. Different materials offer specific protective properties that address various shipping challenges and product requirements.

Foam materials, corrugated cardboard, and specialized cushioning systems provide comprehensive protection for most products. The optimal material combination depends on product characteristics, shipping conditions, and environmental protection requirements during transport.

Foam Materials: Foamed plastic material holds the largest market share at 38.6% in the protective packaging market, driven by high impact absorption, shock resistance, and lightweight construction.

Polyethylene (PE) foam offers excellent cushioning and compression strength for general applications. Expanded polystyrene (EPS) provides superior insulating properties and cost-effectiveness for temperature-sensitive products.

Polyurethane (PU) delivers high-performance protection for sensitive items requiring maximum shock absorption. Anti-static foam is specially designed for electronics to safely dissipate electrostatic charges without damage.

Corrugated Materials: Corrugated cardboard remains the industry standard, featuring a fluted layer sandwiched between two flat linerboards, creating a cushioning effect while maintaining lightweight durability.

Double-wall or triple-wall corrugated cardboard adds additional protection layers for heavier or more fragile items. This construction provides enhanced compression resistance and impact absorption.

Advanced Cushioning Systems: Modern protective materials offer enhanced performance:

- Bubble wrap uses air-filled pockets to absorb shocks and prevent damage to fragile goods

- Air cushioning technology allows air to move between pockets instead of popping, eliminating deflated bubbles

- Hybrid protection solutions combine traditional materials with innovative technologies

Sustainable Materials: Industry trends move toward bio-assimilation films that break down completely into biomass, water, and carbon dioxide after predetermined periods, typically around two years. These materials maintain protective properties during use while addressing environmental concerns.

| Material Type | Primary Benefits | Best Applications |

|---|---|---|

| PE Foam | Cushioning, compression strength | General protection, electronics |

| EPS Foam | Insulation, cost-effectiveness | Temperature-sensitive products |

| PU Foam | High-performance shock absorption | Sensitive, high-value items |

| Anti-static Foam | Electronics protection | Electronic components, devices |

| Corrugated Cardboard | Lightweight, durable, cost-effective | General structural protection |

How Do You Design Custom Packaging for Maximum Protection?

Effective custom packaging design requires systematic analysis of product vulnerabilities and shipping stresses to create solutions that balance protection, cost-effectiveness, and operational efficiency.

Maximum protection design starts with product-specific analysis to determine fragility levels, followed by right-sizing approaches that minimize empty space. Multi-layer protection strategies incorporate outer packaging, interior cushioning, and structural reinforcement validated through comprehensive testing.

Product-Specific Analysis: The first step involves determining the fragility of the product, as more rugged products require less packaging. This assessment guides material selection and design complexity requirements.

Weight distribution analysis affects how forces transfer through packaging during impacts. Fragility mapping identifies critical protection points requiring specialized attention.

Right-Sizing Approach: Custom-sized packaging minimizes empty, redundant space around products. By minimizing empty space, products are secured in place, reducing damage risk from rattling during transit.

Multi-Layer Protection Strategy: Effective design incorporates multiple protection layers working together:

Outer packaging uses sturdy corrugated boxes designed to handle significant weight and external forces. Interior cushioning includes foam inserts, bubble wrap, or air pillows for shock absorption.

Structural reinforcement features reinforced corners and edges to absorb impact and prevent crushing. Environmental barriers provide moisture-resistant materials and thermal insulation as needed.

Testing and Validation: Rigorous testing procedures ensure packaging can withstand expected impacts and stresses through drop tests, compression tests, and vibration tests.

Advanced testing options help identify root causes of packaging challenges, including material failures or temperature and altitude issues. This validation ensures design effectiveness before full implementation.

Automation Integration: Modern custom packaging design considers automated packaging systems that can consolidate packaging into height-reduced containers or convert packages into mailer-sized parcels, helping save money on freight costs.

At Acreet, our packaging engineers work closely with clients to analyze specific product requirements and shipping conditions. We provide comprehensive design services that optimize protection while maintaining cost-effectiveness and operational efficiency for your business needs.

What Are the Latest Innovations in Protective Custom Packaging?

The packaging industry continues evolving with breakthrough innovations that enhance protection capabilities while addressing sustainability concerns and operational efficiency requirements.

Smart packaging technologies, advanced material science, and automated right-sizing systems represent the latest advances in custom packaging protection. These innovations provide enhanced protection capabilities while meeting modern sustainability requirements and operational efficiency demands.

Smart Packaging Technologies: IoT-enabled smart packaging allows consumers to interact with packaging through smartphones, enabling features such as tracking freshness, displaying nutritional information, and indicating when products are nearing expiry.

These technologies help reduce waste while enhancing protection through real-time monitoring of shipping conditions. Impact sensors and temperature monitors provide comprehensive shipment tracking and damage prevention.

Advanced Material Science: Bio-assimilation films represent a breakthrough in sustainable packaging, designed to break down completely into biomass, water, and carbon dioxide after predetermined periods, typically around two years.

This ensures materials maintain protective properties during use while addressing end-of-life environmental concerns. Moisture-resistant paper alternatives achieve performance levels approaching PE-coated materials while maintaining recyclability.

Automated Right-Sizing Systems: On Demand Packaging systems can produce hundreds of official FEFCO and custom box styles designed to fit specific products perfectly.

These systems eliminate 98% of expanded polyethylene while reducing volume by up to 67% and raising pallet density. This optimization reduces material costs while improving protection effectiveness.

AI-Powered Optimization: DecisionTower with AI vision technology enables automated paper-based void filling that optimizes protection while reducing material usage. These systems analyze product requirements and automatically adjust packaging specifications.

Hybrid Protection Solutions: 2024 marked the emergence of hybrid packaging solutions combining traditional materials with innovative technologies. These solutions provide enhanced protection while maintaining cost-effectiveness and sustainability.

How Can Businesses Implement Custom Packaging Protection Solutions?

Successful implementation of custom packaging protection requires systematic planning and partnership with experienced packaging providers. The process involves assessment, design development, testing, and gradual rollout phases.

Successful implementation begins with comprehensive assessment of specific product and packaging requirements, followed by partner selection and design development. Testing validation ensures effectiveness before gradual implementation with continuous improvement monitoring.

Assessment and Planning Phase: Begin by understanding specific product and packaging requirements, including how many different products can share the same box structure and production volume requirements.

Assess weight, size, and fragility of products to determine appropriate protection levels. Evaluate current damage rates and associated costs to establish baseline performance metrics.

Partner Selection: Look for packaging providers that can support runs as low as thousands or tens of thousands rather than only high-volume operations. Evaluate their capabilities in custom foam fabrication, die-cutting, heat welding, and CAD cutting.

Consider providers with comprehensive testing facilities and design expertise. Partnership quality significantly impacts implementation success and long-term performance.

Design Development: Work with packaging experts to develop tailored solutions addressing specific product vulnerabilities. This includes custom foam inserts, corrugated inserts, and specialized cushioning materials.

Consider modular design approaches that balance customization with cost-effectiveness. Integrate branding opportunities while maintaining protection effectiveness.

Testing and Validation: Implement comprehensive testing procedures including environmental testing for temperature, humidity, and atmospheric conditions. Conduct physical testing for drop, compression, and vibration resistance.

Perform material testing for burst strength, tensile strength, and adhesion properties. This validation ensures design effectiveness before full-scale implementation.

Gradual Implementation: Start with pilot programs for high-value or frequently damaged products before expanding to the full product line. This allows for refinement of processes and demonstration of ROI before major investments.

Quality Control Systems: Establish regular quality checks and train staff on proper packaging procedures. Implement impact indicators or shock labels to detect and record impacts during transportation.

Continuous Improvement: Monitor damage rates, customer feedback, and return statistics to identify areas for improvement. Use this data to optimize packaging designs and reduce costs while maintaining protection levels.

The investment in custom packaging protection represents a very inexpensive type of insurance that provides very worthwhile returns through reduced damage, improved customer satisfaction, and enhanced brand reputation.

At Acreet, we guide businesses through every implementation phase, from initial assessment to ongoing optimization. Our comprehensive approach ensures your custom packaging protection delivers maximum value while reducing shipping damage costs and improving customer satisfaction.

Contact our packaging experts today to discuss your specific product protection needs and discover how our custom packaging solutions can transform your shipping success while building stronger customer relationships.

Summary

Custom packaging provides essential protection for products during shipping by creating perfect-fit solutions that prevent movement and absorb impacts. With shipping damage costing businesses 0.5% of gross sales annually and 57% of consumers avoiding repeat purchases after receiving damaged items, custom packaging offers proven ROI through reduced damage rates and improved customer retention. From specialized materials to innovative design approaches, custom packaging solutions deliver comprehensive protection that standard boxes cannot match.

Ready to protect your products with custom packaging solutions? Contact Acreet today for a free consultation and discover how our experienced team can design the perfect packaging protection system for your business needs.