If you’ve ever wondered how emergency food supplies stay fresh for decades or how specialty coffee maintains its aroma for months, you’re facing the same storage challenge that countless businesses solve daily. The answer lies in advanced barrier packaging technology that’s revolutionizing long-term preservation.

Mylar bags are specialized storage pouches made from biaxially-oriented polyethylene terephthalate (BoPET) with metallized aluminum coating that creates exceptional barriers against oxygen, moisture, light, and physical damage. They’re used for long-term storage because they can extend shelf life to 25-30 years when properly sealed with oxygen absorbers, making them essential for food preservation, emergency preparedness, and protecting sensitive products.

Let’s explore everything you need to know about these remarkable storage solutions and how they can transform your preservation needs.

Table of Contents

ToggleWhat Chemical Composition Makes Mylar Bags So Effective?

Understanding the sophisticated engineering behind Mylar bags reveals why they outperform ordinary storage materials.

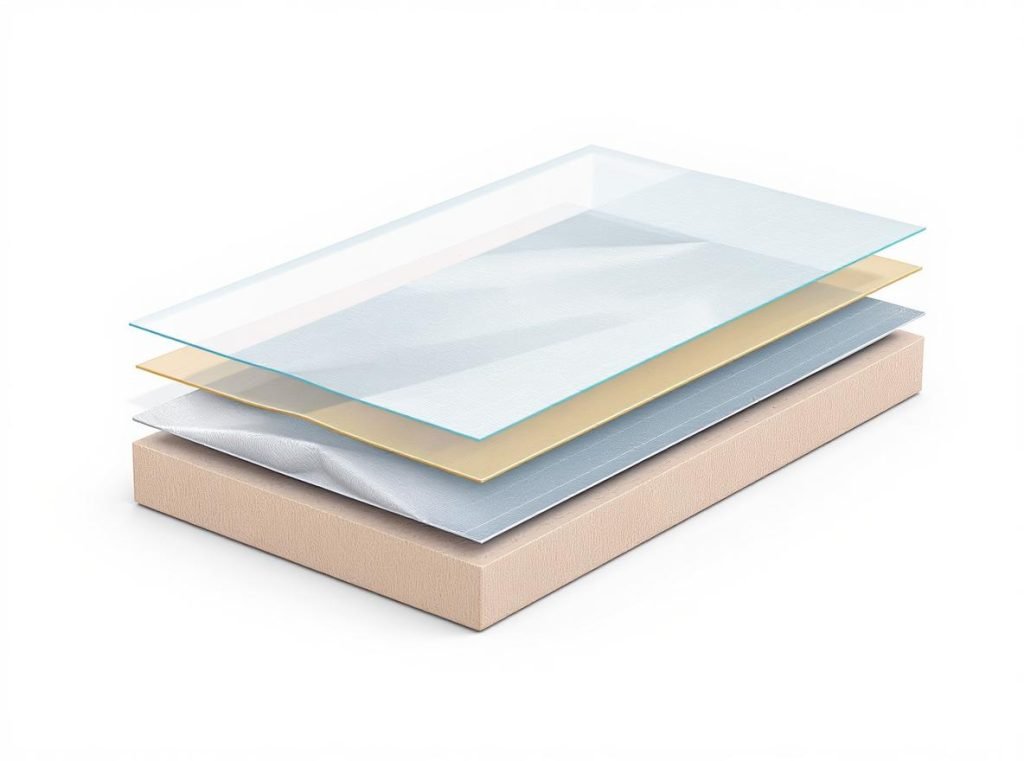

Mylar bags consist of a core layer of biaxially-oriented polyethylene terephthalate (BoPET) with chains oriented in two directions for strength, topped with vacuum-deposited aluminum metallization for barrier properties, and often include polyethylene layers for heat-sealability and food safety.

The manufacturing process creates a material with extraordinary properties. Originally developed in the 1950s by DuPont, Hoechst, and ICI, BoPET film earned the trademark name “Mylar” and quickly proved indispensable in aerospace, electronics, and archival storage applications.

The secret lies in the multi-layer construction:

Core BoPET Layer: Provides tensile strength exceeding 25,000 psi, dimensional stability, and chemical resistance. The biaxial orientation process stretches the polymer chains in two directions, creating exceptional tear resistance.

Aluminum Metallization: A vacuum-deposited aluminum layer thinner than human hair blocks light completely and reduces oxygen transmission to near-zero levels. This metallization is what gives Mylar bags their characteristic silver appearance.

Protective Layers: Premium food-grade bags include inner polyethylene layers that isolate the aluminum from direct food contact while enabling heat-sealing. Outer layers provide additional puncture resistance.

| Property | Typical Value | Performance Benefit |

|---|---|---|

| Tensile Strength | ≥25,000 psi | Resists tears and stretching |

| Oxygen Transmission Rate | <0.01 cc/100 in²-day | Prevents oxidation and pest infestation |

| Moisture Vapor Transmission | <0.05 g/100 in²-day | Blocks humidity and prevents mold |

| Light Transmission | 0% (metallized) | Complete UV and visible light protection |

How Do Mylar Bags Create Superior Protection?

The multi-layered defense system of Mylar bags addresses every major threat to long-term storage success.

Mylar bags protect contents through six critical mechanisms: gas barrier properties that eliminate oxygen infiltration, moisture barriers preventing humidity damage, complete light blocking that preserves nutrients and potency, mechanical strength resisting physical damage, aroma retention that locks in volatile compounds, and electrostatic protection for sensitive materials.

Each protective mechanism works synergistically to create an environment where degradation essentially stops:

Gas Barrier Excellence: The aluminum metallization combined with BoPET orientation creates oxygen transmission rates below 0.01 cc/100 in²-day. This near-zero permeability prevents rancidity in fats and eliminates the oxygen that aerobic microorganisms need to survive.

Moisture Control: With moisture vapor transmission rates under 0.05 g/100 in²-day, Mylar bags keep hygroscopic materials dry even in humid climates. This prevents caking in powders, mold growth, and texture degradation.

Complete Light Barrier: The opaque aluminum layer blocks 100% of UV and visible light that would otherwise degrade vitamins, alter pigments, and reduce potency in light-sensitive compounds.

Mechanical Protection: Seven-mil Mylar film withstands burst pressures exceeding 140 psi—equivalent to five cinder blocks per square inch. This strength resists warehouse handling damage and sharp-edged contents.

Aroma Preservation: Gas impermeability locks in volatile flavor molecules and terpenes critical for maintaining quality in coffee, spices, and aromatic products.

Static Protection: BoPET’s dielectric properties shield electronic components from electrostatic discharge and dust accumulation during storage.

Which Products Achieve Maximum Benefit from Mylar Storage?

Mylar bags excel with specific product categories while requiring special considerations for others.

Products that achieve maximum benefit from Mylar storage include dry goods with less than 10% moisture content and low fat content, such as white rice, hard grains, pasta, dehydrated vegetables, freeze-dried fruits, legumes, and powdered products. These can achieve 10-30 year shelf life when properly stored.

The key to successful Mylar storage lies in matching the right products to this preservation method:

Ideal Candidates for Long-Term Storage:

- White Rice: Achieves 10-30 year shelf life with proper sealing and oxygen absorbers

- Hard Grains (wheat, spelt, oats): Maintain grinding quality for 10+ years

- Pasta: Resists degradation for 20-30 years when protected from sharp edge damage

- Dehydrated Vegetables: Retain color and nutrition for 10-20 years

- Freeze-Dried Fruits: Preserve vitamin C and texture for up to 25 years

- Legumes: Beans and lentils stay viable for 25+ years, with oxygen absorbers preventing pest emergence

| Product Category | Shelf Life in Mylar + Oxygen Absorbers | Special Considerations |

|---|---|---|

| White Rice | 10-30 years | Rotate every 20 years for optimal texture |

| Hard Grains | 10+ years | Grind after opening for freshest flour |

| Pasta | 20-30 years | Use 7-mil bags to resist sharp edges |

| Dehydrated Vegetables | 10-20 years | Ensure ≤10% moisture before sealing |

| Freeze-Dried Fruits | 25 years | Maintains color and vitamin content |

| Coffee Beans | 1-2 years | Requires degassing valve for CO₂ release |

Limited-Term Storage Products require special handling due to higher oil or moisture content. Brown rice, nuts, seeds, and jerky can be stored for 1-5 years maximum because oils turn rancid despite low oxygen environments.

Unsuitable Products include fresh produce, raw meat, soft cheeses, and high-moisture foods (>10%) that risk botulism when sealed anaerobically.

How Thick Should Mylar Bags Be for Different Storage Needs?

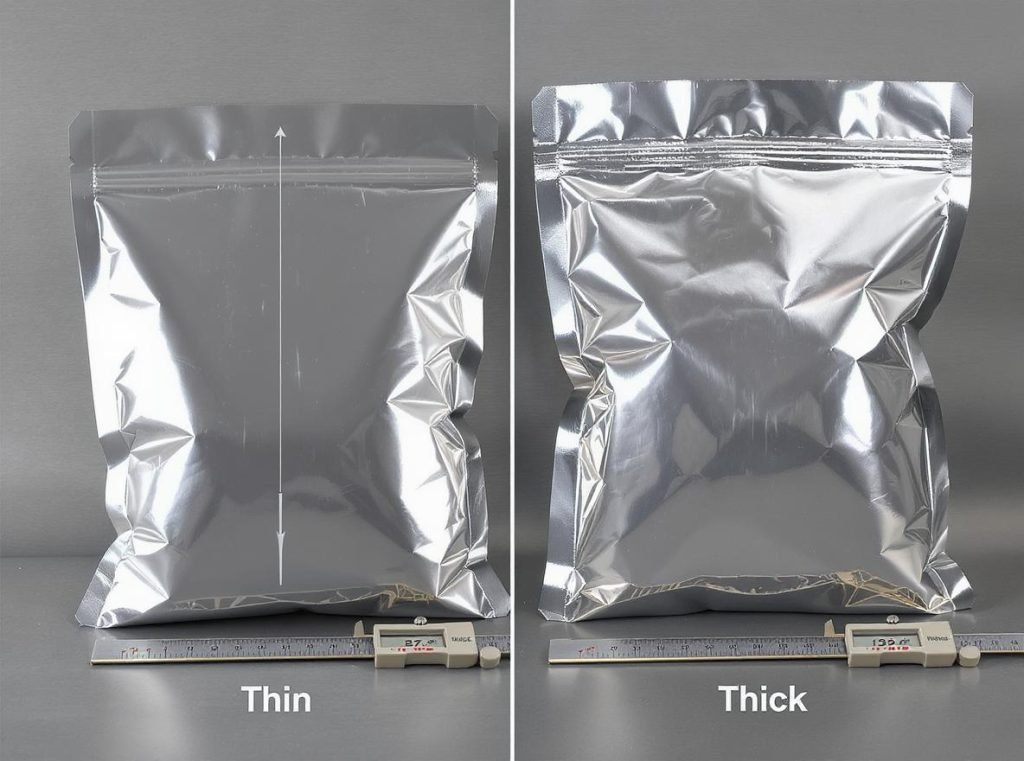

Choosing the correct thickness directly impacts storage success and cost efficiency.

For long-term storage applications, thickness should range from 5-7 mils for standard use up to 10+ mils for extreme conditions. Seven-mil bags provide the optimal balance for 10-30 year storage, offering superior puncture resistance and gas barrier properties while remaining cost-effective for most applications.

Understanding mil measurements helps make informed decisions. One mil equals 0.001 inch—human hair measures approximately 2 mils for comparison.

Thickness Selection Guide:

2-3.5 Mil Bags: Suitable for single-serve portions and short-term storage (under 1 year). These lightweight bags are inexpensive and easy to seal but tear easily under stress and offer limited shelf life extension.

4-5 Mil Bags: The standard choice for retail food pouches and medium-term storage (1-5 years). They balance flexibility with durability but require bucket liners for bulk storage and lack rodent resistance.

7 Mil Bags: Premium thickness for serious long-term storage (10-30 years). These bags offer superior puncture resistance, enhanced gas barrier properties, and withstand rough handling. The extra cost pays dividends for valuable or irreplaceable items.

10+ Mil Bags: Heavy-duty options for industrial applications, sharp-edged products, or extreme storage conditions. Nearly rodent-proof with maximum puncture resistance, though they’re stiffer and harder to fold and seal.

Professional Recommendation: Dry staples intended for storage exceeding 10 years should use 7-mil film or higher, or be placed in 5-gallon buckets lined with 5-mil Mylar for rodent protection.

What’s the Correct Sealing Process for Maximum Effectiveness?

Proper sealing technique determines whether your storage investment succeeds or fails after years in storage.

Effective Mylar bag sealing requires consistent heat application at 300-400°F using impulse sealers, household irons, or specialized equipment. The process involves proper oxygen absorber sizing, debris-free sealing areas, correct temperature and timing, and leak testing to ensure long-term integrity.

The sealing process requires attention to detail at every step:

Equipment Selection:

- Impulse Heat Sealers (12-18 inch): Professional choice for consistent results, especially essential for 7-mil film

- Household Iron: Acceptable for 4-5 mil bags when set to “wool” temperature (≈300°F) and pressed 1-2 seconds per inch

- Hair Straightener: Convenient for small bags but requires careful temperature control

Step-by-Step Sealing Protocol:

- Pack Contents: Fill bags leaving 2-inch headspace and shake to settle contents

- Add Oxygen Absorbers: Insert appropriately sized packets and work within 30 minutes of opening absorber pouch

- Prepare Sealing Area: Remove all debris and moisture from sealing zone to prevent channel leaks

- Apply Heat: Use continuous pressure until indicator light extinguishes or iron glides smoothly for 1-2 seconds

- Leak Test: After cooling, gently squeeze—no air should escape (bag may not visibly shrink due to nitrogen)

- Secondary Protection: Store in rodent-proof containers or 5-gallon buckets with gasket lids

- Label Properly: Record contents, pack date, and oxygen absorber size with waterproof markers

Oxygen Absorber Sizing Guide:

| Bag Size | Food Weight | Required Absorber Capacity |

|---|---|---|

| 1 Pint (6″×8″) | 0.5-1 lb | 100 cc |

| 1 Quart (8″×12″) | 1-3 lb | 300 cc |

| 1 Gallon (10″×14″) | 3-7 lb | 500 cc |

| 5 Gallon Liner | 25-35 lb | 2×2,000 cc |

Why Do Mylar Bags Outperform Alternative Storage Methods?

Comprehensive comparison reveals why Mylar bags have become the preferred choice for serious long-term storage.

Mylar bags combined with oxygen absorbers provide near-zero oxygen transmission rates, complete light barriers, 10-30 year shelf life potential, and cost-effective scalability that surpasses vacuum sealing, glass jars, and metal cans for most applications. They offer the best balance of protection, flexibility, and economic efficiency.

Direct comparison demonstrates clear advantages across multiple criteria:

Versus Vacuum Sealer Bags: Standard vacuum bags allow gradual oxygen infiltration over months, limiting shelf life to 1-3 years. Mylar’s metallized barrier maintains near-zero permeability indefinitely.

Versus Mason Jars: While glass provides excellent protection, it’s heavy, fragile, and expensive for large quantities. Glass also offers no light protection unless stored in dark locations.

Versus Metal Cans: Professional #10 cans offer comparable shelf life but require commercial seaming equipment, can’t be resealed, and cost significantly more per unit of storage.

| Storage Method | Oxygen Barrier | Light Protection | Shelf Life | Cost Efficiency | Flexibility |

|---|---|---|---|---|---|

| Mylar + Oxygen Absorbers | Near-zero OTR | Complete (opaque) | 10-30 years | Excellent | High |

| Vacuum Sealer Bags | Gradual infiltration | None (transparent) | 1-3 years | Moderate | Medium |

| Mason Jars | Excellent (sealed) | None (transparent) | 1-3 years | Poor (heavy/fragile) | Low |

| #10 Metal Cans | Excellent | Complete | 30+ years | Poor (equipment) | None |

Additional Advantages:

- Flexible sizing accommodates various product volumes

- Lightweight for emergency preparedness and transport

- Resealable options available for frequent access

- Custom printing capabilities for commercial applications

What Limitations Should You Consider Before Implementation?

Understanding Mylar bag limitations ensures realistic expectations and proper planning for storage systems.

Key limitations include vulnerability to rodent damage without protective containers, difficulty recycling the plastic-aluminum composite, dependency on heat-sealing equipment, unsuitability for high-moisture foods due to botulism risks, and weight considerations for bulk storage applications.

Planning around these limitations ensures storage success:

Physical Vulnerabilities: Mice can chew through 5-mil film, requiring secondary protection in rodent-proof containers. Sharp contents or rough handling can puncture bags without adequate cushioning.

Environmental Concerns: The plastic-aluminum composite structure makes recycling challenging. Eco-conscious users may prefer mono-material alternatives despite reduced barrier performance.

Equipment Dependencies: Effective sealing requires electricity and proper heat-sealing devices. Field applications without power access become problematic.

Food Safety Restrictions: High-moisture foods (>10% water activity) risk Clostridium botulinum toxin production in anaerobic environments. Never use Mylar bags for fresh produce, raw meat, or soft cheeses.

Handling Considerations: Five-gallon bags filled with grain exceed 30 pounds, requiring safe lifting techniques and adequate shelf support systems.

Temperature Sensitivity: Extreme temperatures can affect seal integrity and material properties. Storage in stable temperature environments optimizes performance.

Which Industries Benefit Most from Mylar Bag Technology?

Diverse industries have adopted Mylar bags for specialized applications beyond basic food storage.

Industries achieving maximum benefit include specialty coffee roasters requiring freshness preservation, cannabis companies needing child-resistant and odor-proof packaging, pharmaceutical manufacturers protecting moisture-sensitive compounds, electronics companies preventing corrosion, and emergency preparedness suppliers creating long-term food reserves.

Each industry has developed specific applications and standards:

Specialty Coffee Industry: Roasters use 4-6 mil matte black Mylar with one-way degassing valves to preserve volatile aromatics while allowing CO₂ release. Custom printing showcases brand identity while maintaining product quality.

Cannabis and CBD: Regulations mandate child-resistant closures and odor-proof containers. Five-mil opaque Mylar with certified zippers meets compliance requirements while protecting light-sensitive cannabinoids.

Pharmaceutical Applications: Companies use Mylar for blister-foil overwraps, diagnostic kit protection, and moisture-sensitive raw materials. Tamper-evident seals and lot coding ensure product integrity and regulatory compliance.

Electronics Manufacturing: Static-dissipative Mylar protects printed circuit boards and sensitive components from moisture and electrostatic discharge during shipping and storage.

Emergency Preparedness: Government agencies and humanitarian organizations rely on 7-mil Mylar liners in 5-gallon buckets for creating shelf-stable food supplies lasting decades.

| Industry Sector | Primary Application | Special Features Required |

|---|---|---|

| Specialty Coffee | Freshness preservation | One-way valves, matte finish |

| Cannabis/CBD | Compliance packaging | Child-resistant, odor-proof |

| Pharmaceuticals | Moisture protection | Tamper-evident, lot coding |

| Electronics | Component protection | Static-dissipative layers |

| Emergency Preparedness | Long-term food storage | Heavy-duty puncture resistance |

How Can Custom Packaging Solutions Enhance Your Storage Strategy?

Professional packaging design transforms basic storage into comprehensive brand and protection solutions.

Custom Mylar packaging enables optimized sizing for specific products, specialized barrier properties for challenging requirements, integrated functionality like resealable closures, high-definition printing for brand recognition, and quality assurance standards that exceed generic options. Professional customization can improve storage efficiency while reducing long-term costs.

Working with experienced packaging manufacturers offers significant advantages over standard retail options:

Precision Engineering: Custom dimensions eliminate wasted space and reduce material costs while providing perfect fit for specific products. This proves especially valuable for commercial operations storing large quantities.

Enhanced Barrier Technology: Specialized coatings and multi-layer constructions provide superior protection for challenging storage requirements. Different metallization levels or alternative barrier materials address specific application needs.

Integrated Functionality: Features like tear notches, resealable zippers, hang tabs, and pour spouts match retail display requirements while improving user experience.

Brand Communication: High-definition printing in up to 10 colors creates shelf impact and provides space for nutritional information, regulatory warnings, and brand storytelling.

Quality Assurance: Professional manufacturers ensure consistent barrier properties, reliable sealing characteristics, and regulatory compliance across large production runs.

At Acreet, we understand that effective storage solutions require more than standard packaging. Our custom Mylar solutions incorporate decades of packaging expertise to create storage systems optimized for your specific requirements.

Custom Capabilities We Provide:

- Specialized thickness and barrier combinations for unique applications

- Food-grade inks and adhesives compliant with FDA regulations

- Child-resistant closures for regulated industries

- Size optimization reducing material costs and storage space

- Technical consultation for complex storage challenges

- Quality certifications for pharmaceutical and food applications

Whether you need enhanced barrier properties for sensitive products, integrated functionality for retail applications, or specialized compliance features for regulated industries, custom packaging transforms storage efficiency and brand presentation.

Summary

Mylar bags represent the gold standard for long-term storage, combining advanced materials science with practical functionality. Made from biaxially-oriented polyethylene terephthalate with aluminum metallization, they provide unmatched protection against oxygen, moisture, light, and physical damage. When properly sealed with appropriate oxygen absorbers, these bags can preserve dry goods for 25-30 years while maintaining nutritional value and quality.

Ready to optimize your storage solutions with professional Mylar packaging? Contact Acreet today to discuss your specific requirements and discover how our custom packaging expertise can enhance your long-term storage success and brand presentation.