Are you struggling to find the perfect packaging solution for your long, narrow, or flat products? Many businesses face challenges when shipping items like fishing poles, picture frames, or metal rods that don’t fit standard box dimensions. Poor packaging choices can result in damaged goods, unhappy customers, and costly returns that eat into your profit margins.

Five-Panel Folder (FPF) boxes offer superior protection, cost-effectiveness, and versatility for packaging long, narrow, and flat items. These single-piece corrugated containers provide exceptional stacking strength, easy assembly, and customizable dimensions, making them ideal for shipping everything from golf clubs to industrial pipes while reducing packaging costs and damage rates by up to 30%.

But there’s much more to discover about how FPF boxes can transform your packaging strategy and boost your business efficiency across multiple industries.

Table of Contents

ToggleWhat Makes Five-Panel Folder Boxes Superior for Long and Narrow Items?

When standard rectangular boxes leave too much empty space or don’t accommodate your product dimensions, you need a specialized solution. Traditional packaging often fails to protect elongated items, leading to punctures, damage, and customer dissatisfaction.

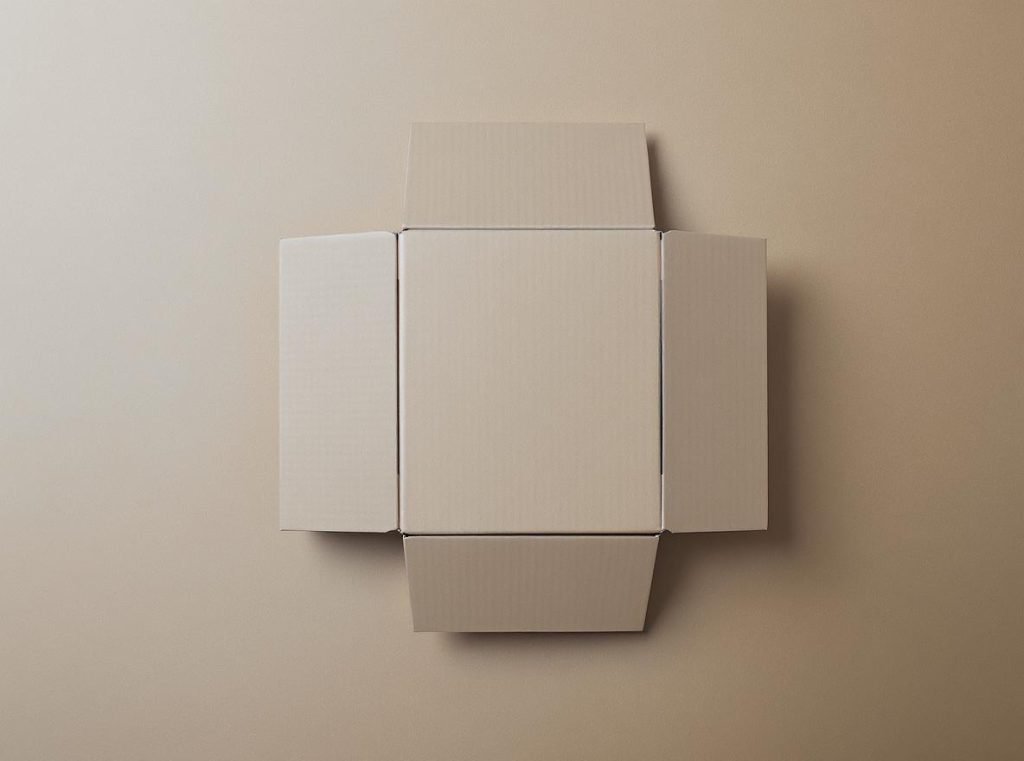

Five-Panel Folder boxes are specifically engineered with five distinct panels, where the fifth panel serves as a closing flap that completely covers a side panel when assembled. This creates several layers of combined board on each end, providing exceptional stacking strength and protection for long articles with small diameters.

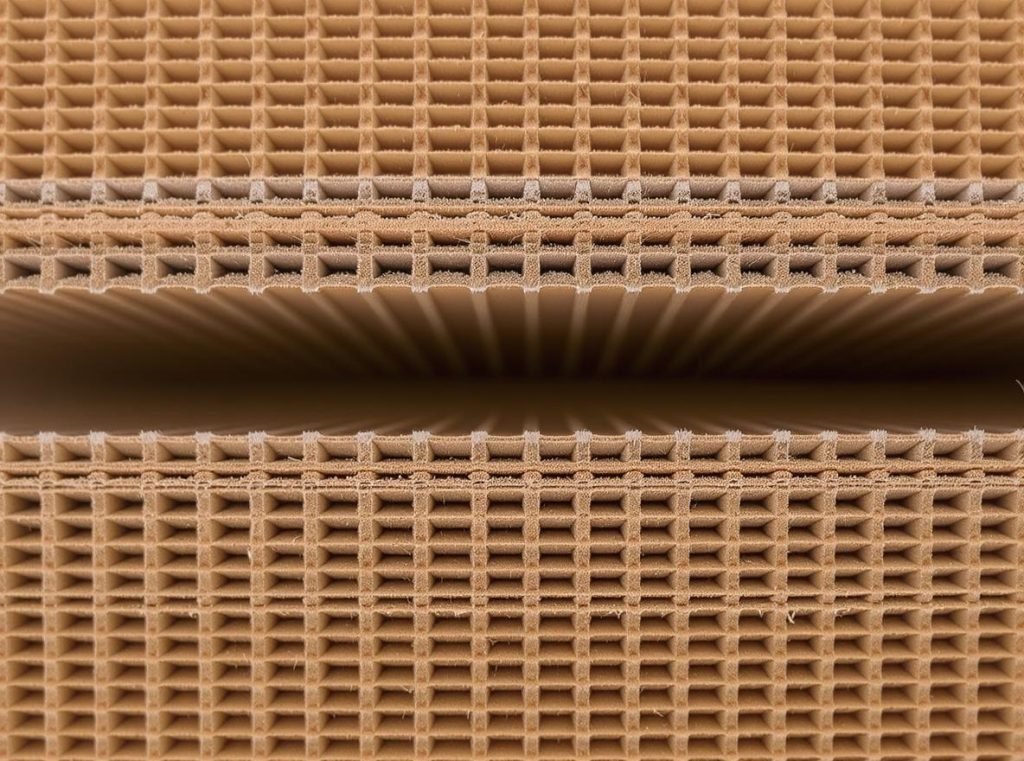

The construction involves a single piece of cut and scored corrugated material that features strategic creases for precise folding. When assembled, three sides of the box contain multiple layers of corrugated material, providing enhanced cushioning and stacking capability that prevents items from piercing through the packaging ends.

Consider these specialized applications where FPF boxes excel:

- Sporting goods: Golf clubs, fishing rods, hockey sticks, baseball bats, and ski poles

- Industrial components: Metal pipes, rods, tubes, rails, and structural elements

- Home improvement: Curtain rods, blinds, light fixtures, and building materials

- Electronics: Long cables, extension cords, and narrow electronic components

- Arts and crafts: Posters, blueprints, rolled charts, and artwork protection

The wrap-around design allows users to simply place the product on the flat corrugated sheet and wrap the box around it, creating a secure, form-fitting enclosure that eliminates excess packaging materials and reduces shipping costs.

How Do Five-Panel Folder Boxes Provide Multi-Layer Protection?

Product protection during shipping remains every business owner’s top priority, especially for delicate elongated items. FPF boxes address these concerns through their innovative multi-layer construction methodology that surpasses traditional single-panel alternatives.

The five-panel design creates exceptional stacking strength and impact resistance through several layers of combined board on each end. This multi-layered construction prevents long articles from damaging the packaging or being damaged during transit, offering protection levels that traditional packaging cannot match.

The robust design delivers superior protection through multiple engineering features:

| Protection Feature | Single-Panel Box | Five-Panel Folder |

|---|---|---|

| End reinforcement | Single layer | Multi-layer combined board |

| Puncture resistance | Limited | Excellent |

| Stacking strength | Moderate | Exceptional |

| Impact protection | Basic | Superior |

| Crushing resistance | Standard | Enhanced |

The closed box configuration creates a sturdy base that can support substantial weight when boxes are stacked during storage or transportation. This enhanced stacking capability makes them ideal for warehouse environments and long-distance shipping operations.

Professional packaging experience shows that FPF boxes reduce damage rates by up to 30% compared to standard packaging methods for long items. The combination of layers makes the box more resistant to crushing, punctures, and bending, protecting goods inside from damage during handling and transportation.

Why Are Five-Panel Folder Boxes More Cost-Effective Than Traditional Packaging?

Every business seeks packaging solutions that balance quality with affordability. FPF boxes deliver exceptional value through multiple cost-saving mechanisms that significantly impact your bottom line across various operational aspects.

FPF boxes reduce packaging costs through efficient material usage, minimal storage requirements, and streamlined assembly processes. Their flat-pack design saves up to 75% storage space compared to pre-formed boxes, while the single-piece construction minimizes material waste and production costs.

The cost advantages become apparent across several business operations:

Material Efficiency and Waste Reduction

FPF boxes are manufactured from a single piece of corrugated material, which minimizes waste and reduces production costs. This efficient manufacturing process translates to lower per-unit costs compared to multi-piece packaging solutions.

Storage and Logistics Savings

The flat-pack delivery system reduces storage space requirements and shipping expenses significantly. Warehouses can store large quantities of boxes in minimal space, improving inventory management and reducing storage costs.

Labor Cost Optimization

The simple assembly process requires minimal time and no special tools or glue. Workers can quickly wrap products without complex folding sequences, eliminating the need for time-consuming assembly procedures and reducing labor costs in high-volume operations.

Reduced Additional Materials

The form-fitting design eliminates the need for additional cushioning materials like bubble wrap or foam inserts. This reduction in packaging materials decreases overall packaging expenses by 20-40% while maintaining superior protection.

Which Industries Benefit Most from Five-Panel Folder Box Solutions?

Understanding which industries gain the most from FPF boxes helps businesses make informed packaging decisions. The specialized design makes these boxes indispensable across multiple sectors that frequently handle challenging product dimensions.

Manufacturing, construction, sporting goods, electronics, and food processing industries benefit significantly from FPF boxes. These sectors frequently ship products with elongated dimensions that standard packaging cannot accommodate effectively while maintaining cost-efficiency.

Manufacturing and Construction Industry

Heavy machinery components, metal fabrication parts, and industrial tools require custom-fit packaging. Construction companies utilize FPF boxes for shipping rails, fence components, and structural elements. The boxes’ ability to handle heavy, long items makes them indispensable in industrial settings.

Sporting Goods and Recreation

The sporting goods industry relies heavily on FPF boxes for equipment protection during shipping. Items like fishing rods, golf clubs, baseball bats, and similar elongated equipment require specialized packaging that FPF boxes provide through their reinforced end construction.

Food and Beverage Processing

FPF boxes are extensively used for multipack food products and elongated food items. The corrugated construction provides food-safe packaging while maintaining product integrity during distribution, with the added benefit of handling various product sizes efficiently.

Electronics and Technology

Long cables, extension cords, and specialized electronic components benefit from FPF boxes’ protective qualities. The anti-static properties and protection capabilities make them suitable for sensitive electronic components that require careful handling.

Arts and Automotive Applications

Museums, art galleries, and printing companies use FPF boxes to protect valuable materials like posters, blueprints, and artwork. The automotive industry packages long components, tools, and accessories using these boxes for their durability and customization options.

How Simple Are Five-Panel Folder Boxes to Assemble and Use?

Packaging efficiency depends heavily on how quickly and easily workers can assemble containers. Complex packaging solutions slow down operations and increase labor costs, making assembly simplicity a crucial factor in packaging selection.

Five-Panel Folder boxes require minimal assembly time using only standard packaging tape, with no glue or specialized tools needed. Workers can assemble these boxes in seconds through a simple wrap-around process, making them ideal for high-volume shipping operations.

The assembly process follows these straightforward steps:

- Place the flat corrugated sheet next to your product

- Position the item on the box base section

- Wrap the side panels around the product systematically

- Fold the end panels to create secure closure

- Apply packaging tape to seal all edges effectively

Training and Quality Control Benefits

Training requirements remain minimal due to the intuitive design. New employees can learn the assembly process within minutes, reducing onboarding time and increasing productivity. The visible overlap areas allow supervisors to quickly verify proper assembly, ensuring consistent packaging quality.

Operational Efficiency Gains

The wrap-around design allows for efficient loading during fulfillment operations. Simply placing the product on the box and wrapping it around saves time compared to traditional box loading methods, particularly valuable in e-commerce and distribution centers where speed is crucial.

Storage and Handling Advantages

FPF boxes ship flat, significantly reducing storage space requirements before use. This flat-pack design allows warehouses to store large quantities efficiently while the assembled boxes remain stackable for optimal transportation and storage space utilization.

What Environmental Benefits Do Five-Panel Folder Boxes Offer?

Modern businesses increasingly prioritize sustainable packaging solutions as environmental considerations influence purchasing decisions and brand perception among consumers. Sustainability has become a competitive advantage in today’s market.

Five-Panel Folder boxes offer exceptional environmental benefits through 100% recyclable corrugated materials, reduced packaging waste, and optimized transportation efficiency. Manufacturing cardboard produces 60% fewer carbon dioxide emissions compared to alternative packaging materials.

Recyclability and Circular Economy

FPF boxes are manufactured from corrugated cardboard that is completely recyclable and biodegradable. Unlike plastic packaging that takes hundreds of years to decompose, corrugated boxes break down naturally within months, making them an environmentally responsible choice.

Resource Conservation Impact

Using recycled corrugated material for FPF boxes conserves natural resources and reduces demand for virgin materials. The recycling process requires 75% less energy than producing new boxes from raw materials, while recycling one ton of cardboard saves 4,000 kW of electricity and 7,000 gallons of water.

Carbon Footprint Reduction

The lightweight nature of corrugated material reduces transportation-related emissions significantly. The production process generates lower carbon emissions compared to alternative packaging materials, contributing to reduced overall environmental impact.

Renewable Material Foundation

Corrugated boxes are made from wood pulp sourced from renewable tree resources, ensuring the packaging doesn’t deplete non-renewable resources like petroleum-based plastics. Many manufacturers prioritize using recycled content whenever possible, further enhancing environmental benefits.

What Customization Options Are Available for Five-Panel Folder Boxes?

Every business has unique packaging requirements based on product specifications, brand identity, and shipping needs. Customization capabilities determine how well packaging solutions align with specific business objectives and market positioning.

Five-Panel Folder boxes offer extensive customization options including precise dimensions, multiple material grades, advanced printing capabilities, and specialized features. Businesses can specify exact measurements, choose from single-wall to triple-wall corrugated strengths, and incorporate comprehensive branding elements.

Material and Structural Options

FPF boxes can be manufactured using various corrugated materials, including single-wall, double-wall, and triple-wall options depending on strength requirements. Material choices include standard kraft paper, recycled materials, and eco-friendly alternatives that affect strength, weight capacity, and environmental impact.

| Customization Category | Available Options |

|---|---|

| Corrugated Strength | Single, double, triple-wall |

| Printing Methods | CMYK, PMS color matching |

| Finishing Options | Gloss lamination, UV coating, embossing |

| Special Features | Handles, perforations, windows |

| Size Flexibility | Any length, width, height combination |

Branding and Marketing Integration

Extensive printing and branding opportunities include CMYK color printing, PMS color matching, and various finishing techniques such as gloss lamination, UV coating, embossing, and foil printing. These customization options allow businesses to create attractive packaging that enhances brand recognition and customer experience.

Specialized Modifications

Additional features can be incorporated including handles, perforations, window cutouts, and special closures. Custom inserts and dividers can be added to accommodate multiple items or provide additional protection while maintaining structural integrity.

How Do Five-Panel Folder Boxes Compare to Other Packaging Solutions?

Making informed packaging decisions requires understanding how FPF boxes perform relative to conventional alternatives. This comparison helps businesses evaluate whether switching to FPF boxes aligns with their operational goals and cost objectives.

Five-Panel Folder boxes outperform Regular Slotted Containers (RSC), Full Overlap (FOL), and One-Piece Folders (OPF) in specialized applications for long, narrow items. While traditional boxes excel for standard dimensions, FPF boxes provide superior end protection and space utilization for challenging product shapes.

Performance Comparison Analysis

vs. Regular Slotted Containers (RSC)

FPF boxes provide superior protection for long, narrow items compared to RSC boxes. While RSC boxes are versatile and cost-effective for general applications, they lack the specialized end protection that FPF boxes offer through their multi-layered construction and enhanced stacking strength.

vs. Full Overlap (FOL) Boxes

While FOL boxes offer enhanced strength through overlapping flaps, FPF boxes provide more specialized protection for elongated items. FOL boxes excel in heavy, general-purpose applications, but FPF boxes deliver better space utilization and end protection for long, narrow products.

vs. Telescope-Style Boxes

FPF boxes are generally more cost-effective than telescope-style boxes while providing adequate protection for most long-item applications. Telescope boxes offer excellent protection through their two-piece design but require more material and labor for assembly, making FPF boxes more economical for appropriate applications.

Cost-Benefit Analysis

Businesses typically save 25-35% on total packaging costs when switching to FPF boxes for appropriate products. The specialized design eliminates most additional packaging material requirements through form-fitting construction, while flat-pack storage reduces warehouse costs and improves inventory management.

Summary

Five-Panel Folder boxes represent an intelligent packaging solution for businesses shipping long, narrow, or flat products across diverse industries. These specialized containers deliver superior multi-layer protection, significant cost-effectiveness, and exceptional operational efficiency compared to traditional packaging methods. From sporting goods to industrial components, FPF boxes adapt to challenging product requirements while maintaining excellent structural integrity, environmental sustainability, and customization flexibility.

Ready to optimize your packaging strategy with custom Five-Panel Folder boxes? Contact Acreet today for a free consultation and discover how our expertly designed FPF boxes can reduce your packaging costs while improving product protection. Send us your product specifications, and our experienced packaging engineers will create the perfect custom solution tailored to your business needs and industry requirements.