Frozen food businesses face critical packaging challenges that directly impact product quality, shelf life, and consumer satisfaction. Poor packaging leads to freezer burn, moisture loss, and contamination that destroys taste, texture, and profitability.

The best packaging solutions for frozen food products include advanced barrier materials like EVOH films, multi-layer structures, and temperature-resistant plastics that maintain integrity from -40°F to microwave temperatures. With the global frozen food packaging market valued at $11.38 billion in 2024 and projected to reach $17.20 billion by 2032, optimal solutions include flexible pouches, barrier films, and sustainable materials that prevent moisture transfer while enhancing consumer convenience.

Let’s explore the complete range of packaging innovations that protect your products and capture market opportunities.

Table of Contents

ToggleWhat Materials Work Best for Frozen Food Packaging?

Understanding advanced material properties is crucial when products face extreme temperatures and demanding distribution requirements throughout the cold chain.

Plastics dominate the frozen food packaging market with 56.5% market share in 2024, with polyethylene (PE), polypropylene (PP), and advanced barrier materials like EVOH providing superior protection. These materials maintain flexibility at -40°F while offering excellent sealing properties and moisture resistance.

Primary Plastic Materials:

Polyethylene (PE) delivers exceptional flexibility and cold temperature resistance down to -40°F without becoming brittle. PE shrink films maintain integrity throughout freezing and thawing cycles, making them ideal for vegetables, fruits, and portion-controlled products.

Polypropylene (PP) offers superior strength with temperature performance from -4°F to 266°F, enabling both freezing and microwave applications. Food-grade PP maintains hygiene standards at temperatures as low as -30°C while providing excellent durability.

Polyethylene Terephthalate (PET) provides outstanding barrier properties and transparency. Freezer-grade PET prevents cracking and brittleness while offering superior protection against oxygen, moisture, and odors that preserve flavor, texture, and nutritional value.

Advanced Barrier Technologies:

Ethylene Vinyl Alcohol (EVOH) stands out as the optimal transparent high-barrier solution with oxygen permeation rates as low as 0.01-0.1 cm³/m²/day. EVOH maintains barrier properties from -18°C to 100°C, enabling freezer-to-microwave convenience in single packaging solutions.

| Material Type | Temperature Range | Oxygen Barrier | Best Applications |

|---|---|---|---|

| PE Films | -40°F to 32°F | Moderate | Shrink wraps, bags |

| PP Containers | -4°F to 266°F | Good | Dual-purpose packaging |

| PET Films | -40°F to 180°F | Excellent | Premium products |

| EVOH Barriers | -18°C to 100°C | Superior | High-value items |

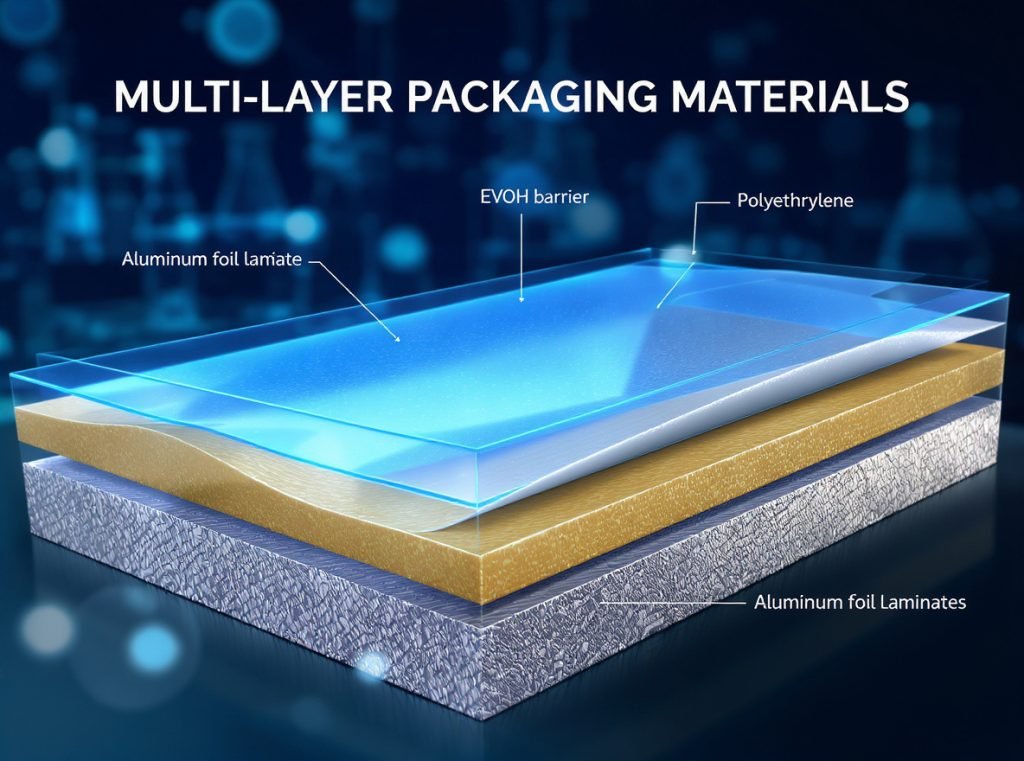

Multi-Layer Innovations:

Advanced structures combining PET/AL/PE offer comprehensive protection where PET provides strength and printability, aluminum delivers maximum barrier properties, and PE enables reliable heat sealing for extended shelf life.

Partner with packaging specialists who understand cold chain requirements and material science. At Acreet, we develop custom packaging solutions using the latest barrier technologies to maintain product quality from production to consumer purchase.

How Do Temperature Requirements Affect Packaging Choice?

Temperature control throughout the supply chain demands packaging engineered for extreme conditions and thermal cycling performance.

Frozen foods must remain at or below -18°C (0°F) to prevent microbial growth and preserve quality. Critical temperature considerations include cold temperature durability, thermal shock resistance, and material brittleness thresholds that directly influence packaging performance.

Critical Temperature Control Points:

Storage Requirements:

Products must maintain temperatures at or below -18°C (0°F) throughout distribution. Temperature fluctuations compromise product safety and quality, requiring materials that perform consistently across temperature ranges.

Brittle Temperature Considerations:

Plastic materials can become brittle at low temperatures, with brittle temperature representing the lower limit of normal use. Low-Density Polyethylene (LDPE) maintains flexibility at freezing temperatures without compromising package integrity.

Thermal Shock Resistance:

Packages must withstand rapid temperature changes during distribution without seal failure or barrier compromise. Advanced materials accommodate thermal cycling while maintaining protection properties.

Multi-Temperature Performance:

Modern packaging solutions must transition from freezer storage (-18°C) to microwave heating without structural failure or chemical migration concerns.

Temperature Stability Applications:

- Blast freezing: -40°F rapid freeze tunnels

- Cold storage: -24°C to -18°C warehouse facilities

- Distribution: Variable temperatures during transport

- Consumer storage: 0°F household freezers

- Preparation: Microwave heating up to 200°F

Temperature testing during package development ensures reliable performance across the entire cold chain. Successful frozen food brands invest in comprehensive thermal testing to validate package integrity under real-world conditions.

Which Packaging Formats Provide the Best Protection?

Different product categories require specific packaging formats optimized for protection, convenience, and market appeal.

Stand-up pouches, vacuum-sealed bags, and thermoformed trays with barrier films provide superior protection while offering consumer convenience features. Flexible packaging generates less waste and requires less material and energy to produce compared to rigid alternatives.

Flexible Packaging Solutions:

Stand-Up Pouches:

Provide multiple advantages over traditional rigid packaging including better retail space utilization through larger customer-facing graphic panels. These formats require less film to produce, reducing environmental impact while offering resealable convenience.

Vacuum Packaging:

Removes oxygen exposure to significantly extend shelf life while preventing freezer burn. Vacuum-sealed packages maintain product integrity and appearance throughout extended storage periods.

Resealable Bags:

Offer convenience features while maintaining airtight protection against freezer burn. These packages support portion control, reducing food waste while preserving product freshness.

Rigid Container Benefits:

Thermoformed Trays:

Advanced thermoformed packages using 95% polyethylene with EVOH barriers provide superior puncture resistance equivalent to nylon films while maintaining full recyclability. These solutions combine structural support with high-barrier protection.

Protective Containers:

Rigid packaging provides superior durability and protection against physical damage, moisture, and contamination during handling and transportation.

| Format Type | Protection Level | Convenience Features | Sustainability |

|---|---|---|---|

| Stand-up Pouches | High | Resealable, space-efficient | Lower material usage |

| Vacuum Bags | Superior | Extended shelf life | Minimal waste |

| Thermoformed Trays | Excellent | Microwave-ready | Recyclable options |

| Rigid Containers | Maximum | Structural integrity | Reusable potential |

Each format addresses specific challenges in frozen food distribution while supporting different market positioning strategies. Work with experienced manufacturers to select formats matching your product requirements and production capabilities.

What Are the Key Benefits of Barrier Packaging?

Advanced barrier properties separate successful frozen food packaging from solutions that lead to product failure and customer dissatisfaction.

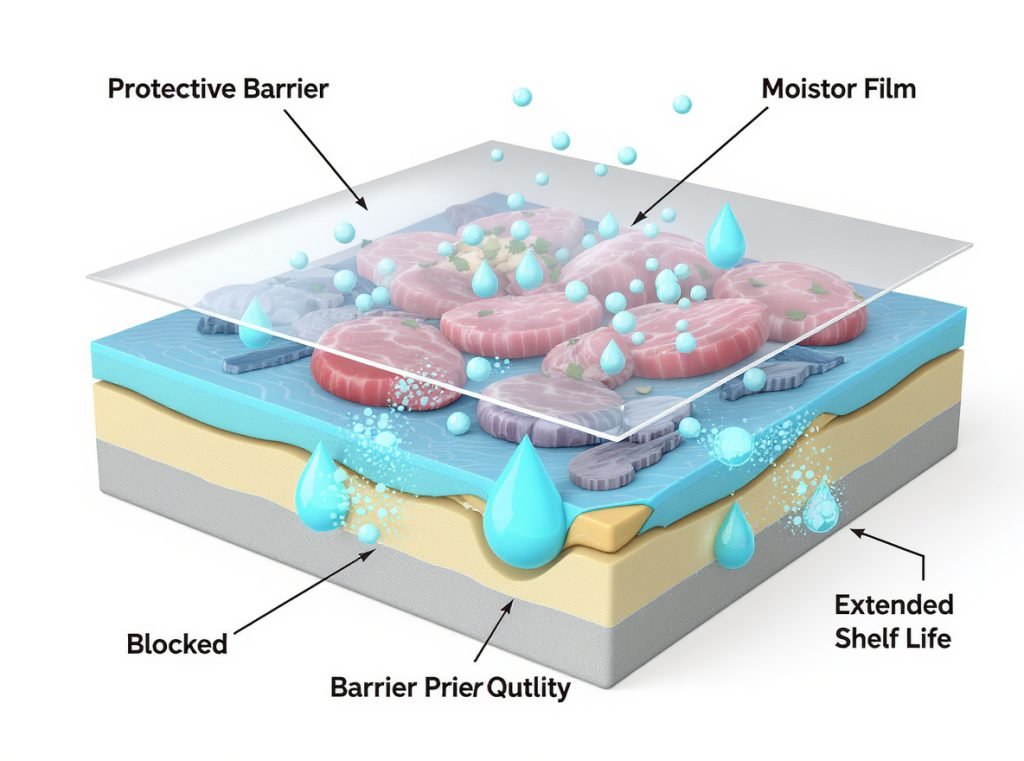

Barrier packaging creates protective shields against moisture, oxygen, and light, extending shelf life up to 18 months while preventing oxidation, spoilage, and degradation. High-barrier materials maintain food’s aroma, taste, texture, and nutritional value throughout distribution.

Essential Protection Properties:

Extended Shelf Life:

Barrier packaging significantly extends product shelf life by creating protective shields against moisture, oxygen, and light. This protection reduces food waste while ensuring consumers receive fresh, high-quality products with maintained nutritional benefits.

Quality Preservation:

Advanced barrier materials prevent oxidation reactions that cause off-flavors, rancidity, and color changes. The protective barrier maintains food’s aroma, taste, texture, and nutritional value throughout the entire distribution chain.

Contamination Prevention:

Barrier packaging blocks external contaminants including dust, pollutants, and microorganisms while reducing reliance on chemical preservatives. This natural preservation method extends shelf life while maintaining food safety standards.

Performance Comparison:

- Single-layer films: Basic protection for short-term storage

- Multi-layer barriers: Extended shelf life for premium positioning

- Aluminum laminates: Maximum protection for export applications

- EVOH structures: Superior transparency with excellent barrier properties

Advanced Barrier Applications:

High-barrier films like TIPA’s compostable options provide superior sealing and barrier properties while supporting environmental sustainability. These innovations deliver conventional protection performance while enabling circular economy principles.

The investment in advanced barrier packaging delivers measurable returns through reduced product loss, extended distribution reach, premium positioning opportunities, and improved customer satisfaction leading to repeat purchases.

How Does Microwaveable Packaging Enhance Consumer Convenience?

The microwaveable food market growth demonstrates strong consumer demand for convenience packaging solutions.

The microwaveable food market, valued at $120 billion in 2020, is projected to reach $230 billion by 2031, with frozen foods comprising over half of the microwaveable packaging market. Advanced packaging enables direct heating while providing oxygen and moisture resistance.

Market Growth Drivers:

Consumer Convenience Demands:

Direct heating capability eliminates transfer to separate containers, saving time and reducing cleanup. Microwave-safe packaging allows consumers to cook frozen meals directly in original packaging while maintaining portion control.

Steamable Technology Benefits:

Steamable packaging provides fast, convenient cooking methods for healthy meals, allowing consumers to steam fresh-frozen vegetables directly in packaging. This technology maintains nutritional benefits equivalent to fresh food with shorter preparation times.

Technical Performance Requirements:

- Heat-resistant seals maintaining integrity during microwave cycles

- Venting systems for safe steam release during heating

- Materials preventing harmful compound release when heated

- Multi-temperature capability from freezer (-18°C) to microwave temperatures

Advanced Technology Solutions:

Susceptor Technology:

Delivers consistent browning and crisping performance through specialized films and coatings. These solutions work efficiently on current sealing equipment while providing restaurant-quality results for premium products.

Dual-Temperature Performance:

Advanced materials transition seamlessly from freezer storage to microwave heating without compromising package integrity or food safety standards.

Microwaveable packaging development requires specialized expertise in material science, sealing technology, and food safety regulations. Successful implementation balances convenience features with protection performance and regulatory compliance.

What Sustainable Options Exist for Frozen Food Packaging?

Environmental consciousness drives packaging innovation without compromising essential product protection and performance requirements.

Sustainable solutions include recyclable plastics like PET and HDPE, compostable films, and mono-material structures that enable full recyclability. Post-consumer recycled content integration and plant-based alternatives address environmental concerns while maintaining barrier performance.

Recyclable Material Innovations:

Mono-Material Structures:

Enable full recyclability by eliminating mixed materials that complicate recycling processes. SmartPack™ technology provides premium barrier performance while maintaining complete recyclability for circular economy compliance.

Post-Consumer Recycled (PCR) Content:

Innovative pouches with over 50% PCR content demonstrate industry commitment to circular economy principles while reducing virgin material usage and environmental impact.

Advanced Recycling Solutions:

PET containers perform well in recycling streams while maintaining excellent barrier properties. HDPE films offer improved environmental profiles with enhanced barrier performance for frozen food applications.

Compostable and Biodegradable Options:

TIPA’s Compostable Films:

Including TIPA 312 MET and T.LAM series offer home and industrial composting options while maintaining high barrier performance. These solutions ensure compliance with global sustainability standards like EN13432.

Plant-Based Alternatives:

Footprint’s fiber packaging eliminates plastic from food chains while providing moisture/oil resistance and microwave safety. These materials reduce carbon emissions throughout production and end-of-life cycles.

| Sustainable Solution | Environmental Benefit | Performance Level | Applications |

|---|---|---|---|

| Mono-Material Design | Full recyclability | High | Premium products |

| PCR Content Integration | Reduced virgin material | Good | Mass market items |

| Compostable Films | Complete biodegradation | Moderate | Eco-conscious brands |

| Plant-Based Fibers | Carbon footprint reduction | Variable | Specialized applications |

Implementation Strategy:

Sustainable packaging requires balancing environmental impact reduction with product protection performance, cost considerations, and consumer acceptance. Leading brands implement gradual transitions supported by consumer education and supply chain partnerships.

How Do You Choose Between Flexible and Rigid Packaging?

The flexible versus rigid packaging decision impacts production efficiency, distribution costs, consumer experience, and market positioning.

Flexible packaging offers cost advantages through lighter weight and reduced material usage, while rigid packaging provides superior protection and premium positioning. The optimal choice depends on product characteristics, distribution requirements, and sustainability goals.

Flexible Packaging Advantages:

Cost and Efficiency Benefits:

Flexible packaging typically costs less to produce and ship due to lighter weight and reduced material usage. Transportation efficiency improves through better pallet utilization and reduced fuel consumption throughout distribution.

Space and Storage Benefits:

Flexible options require less storage space in warehouses and offer better shelf utilization in retail environments. This efficiency translates to reduced warehousing costs and improved retail presentation opportunities.

Consumer Convenience Features:

Resealable closures, easy-open mechanisms, and portion control capabilities enhance user experience. Many flexible packages offer superior convenience features unavailable in rigid alternatives.

Rigid Packaging Advantages:

Protection Performance:

Rigid packaging provides better protection against physical damage and contamination during handling and transportation. This durability ensures product integrity throughout complex distribution networks.

Market Positioning:

Rigid containers often convey premium quality perceptions among consumers, justifying higher price points while enhancing brand image and market positioning.

Operational Benefits:

Rigid containers maintain shape and provide reliable stacking capabilities for efficient logistics and attractive retail displays.

Decision Framework:

| Consideration | Flexible Advantage | Rigid Advantage |

|---|---|---|

| Material Costs | Lower production costs | Premium positioning |

| Transportation | Space-efficient shipping | Damage protection |

| Consumer Appeal | Convenience features | Quality perception |

| Environmental Impact | Reduced material usage | Potential reusability |

Selection Criteria:

Product characteristics, distribution requirements, and target market preferences determine optimal packaging approaches. Fragile products benefit from rigid protection, while convenient portions perform well in flexible formats.

What Custom Design Features Boost Frozen Food Appeal?

Strategic custom design elements differentiate products in competitive retail environments while communicating quality, convenience, and brand values.

Custom design features including high-quality graphics, transparent windows, functional convenience elements, and interactive features significantly impact consumer purchasing decisions and brand perception in frozen food categories.

Visual Impact Elements:

Premium Graphics and Finishes:

High-quality printing and finishes maintain sharp, attractive appearance even after extended freezer storage. Premium visual presentation differentiates products in crowded frozen aisles while supporting brand positioning.

Product Visibility Features:

Transparent windows allow consumers to view product quality before purchase, building confidence and trust. Clear visibility enhances purchase decisions for quality-conscious consumers evaluating frozen food options.

Color Psychology Application:

Vibrant color schemes using cool blues, greens, and silvers create fresh, cold sensations while warm accent colors highlight special features. Bold contrasting designs improve shelf visibility and brand recognition.

Functional Design Features:

Convenience Enhancements:

Easy-open mechanisms enhance consumer experience while maintaining package integrity. User-friendly features accommodate consumers with mobility challenges while supporting accessibility requirements.

Freshness Protection:

Resealable closures provide convenience while preventing freezer burn and maintaining freshness. These features support portion control and reduce food waste while extending product usability.

Smart Technology Integration:

Temperature-indicating labels communicate time-temperature history, helping consumers make informed decisions about product quality. Smart labels enhance food safety while providing valuable consumer information.

Interactive and Engagement Elements:

Digital Integration:

QR codes and digital features provide access to recipes, preparation instructions, and sustainability information. Interactive packaging engages consumers while supporting brand loyalty and repeat purchases.

Custom Experience Features:

Specialized inserts including thank-you notes, promotional codes, and usage guides enhance customer experience and encourage brand engagement throughout the purchase journey.

| Design Element | Consumer Benefit | Brand Advantage | Technical Requirement |

|---|---|---|---|

| Transparent Windows | Quality verification | Trust building | Barrier maintenance |

| Easy-Open Features | Convenience | Accessibility | Seal integrity |

| Smart Labels | Safety information | Innovation positioning | Temperature sensitivity |

| Digital Integration | Extended engagement | Brand loyalty | Durability requirements |

Custom packaging development requires collaboration between marketing, operations, and packaging specialists to balance aesthetic appeal with functional performance while meeting regulatory requirements and production constraints.

Summary

The best packaging solutions for frozen food products combine advanced barrier materials, temperature-resistant performance, and consumer convenience features. With the market projected to reach $17.20 billion by 2032, successful solutions include EVOH barriers, multi-layer structures, flexible pouches, and sustainable materials that maintain product quality while meeting environmental demands. Key considerations include material selection for extreme temperatures, packaging format optimization, and custom design features that enhance market appeal.

Looking to develop innovative packaging solutions for your frozen food products? Contact Acreet today to discuss how our expertise in advanced barrier technologies, temperature-resistant materials, and custom design capabilities can protect your products while enhancing brand positioning. Our team specializes in creating packaging solutions that perform throughout the cold chain while meeting sustainability goals and consumer convenience expectations.

Ready to elevate your frozen food packaging with cutting-edge solutions? Partner with Acreet’s packaging experts to explore advanced barrier materials, sustainable options, and custom designs that differentiate your products in the growing frozen food market. Contact us for comprehensive packaging consultation and custom development services.