When your business needs to ship heavy, fragile, or high-value items, standard packaging simply won’t cut it. You need something stronger, more durable, and capable of withstanding the rigors of long-distance shipping and rough handling.

Triple wall corrugated boxes are the ultimate heavy-duty packaging solution, featuring seven layers total with three corrugated flutes between four linerboards. These boxes can handle weights from 240-300 pounds with standard ECT-90 ratings (1100# burst strength), making them ideal for industrial equipment, bulk goods, export shipping, and any application requiring maximum protection.

Let’s explore exactly when and why you should choose triple wall corrugated boxes for your packaging needs.

Table of Contents

ToggleWhat Makes Triple Wall Corrugated Boxes Different from Other Packaging?

Understanding the construction differences helps you make the right packaging choice for your business needs.

Triple wall corrugated boxes feature seven layers total – three corrugated flutes sandwiched between four flat linerboards, creating a structure that’s significantly stronger than single or double wall alternatives. This 7-ply construction provides superior stacking strength, crush resistance, and protection comparable to wooden crates but at 250% lighter weight and 40-60% lower cost.

The key difference lies in the layered construction. While single wall boxes work for lightweight items and double wall boxes handle medium-weight products, triple wall boxes are engineered for maximum durability. Each layer has differently-sized flutes to add stability, and the added layers maximize cushioning and compression strength.

Here’s how the three types compare:

| Box Type | Layers | Flutes | Weight Capacity | ECT Rating |

|---|---|---|---|---|

| Single Wall | 3 | 1 | Up to 65 lbs | 32-44 ECT |

| Double Wall | 5 | 2 | 80-180 lbs | 48-71 ECT |

| Triple Wall | 7 | 3 | 240-300 lbs | 90-112 ECT |

Triple wall construction typically achieves Edge Crush Test (ECT) ratings of 90-112, with standard specifications of 1100# burst strength. The ECT rating indicates the boxes can withstand 90+ pounds of force per linear inch when compressed vertically, ensuring rigidity under pressure and reliable stacking performance in warehouses.

Common flute combinations include A/C/C for optimal strength-to-weight ratio, B/C/C for balanced strength and printability, and A/A/A for maximum thickness and cushioning. These configurations allow customization based on specific application requirements.

When Should You Use Triple Wall Corrugated Boxes for Heavy-Duty Applications?

Knowing when to upgrade to triple wall packaging can save you money on damaged goods and customer complaints.

Use triple wall corrugated boxes when shipping items over 100 kg (220 lbs), valuable equipment, fragile products requiring extra cushioning, or anything traveling long distances internationally. They’re essential for industrial machinery, automotive parts, electronics, and bulk products weighing 121-300 pounds that need maximum protection during transport.

Heavy industrial equipment represents the most common use case. Triple wall boxes are often used for shipping and storing extremely heavy items such as machinery, equipment, and bulk products. Manufacturing companies regularly use these boxes for engine parts, pumps, generators, and other heavy machinery components.

The automotive industry relies heavily on triple wall packaging for several reasons:

- Parts Protection: Automotive components are expensive and precision-made, requiring secure packaging

- Weight Handling: Many automotive parts exceed standard box weight limits

- Supply Chain Demands: Long shipping distances between manufacturers and assembly plants

- Stacking Requirements: Warehouse storage often involves high stacking

Electronics and technology companies choose triple wall boxes for sensitive equipment shipments. The multiple layers provide excellent vibration dampening and impact protection for servers, industrial computers, and precision instruments.

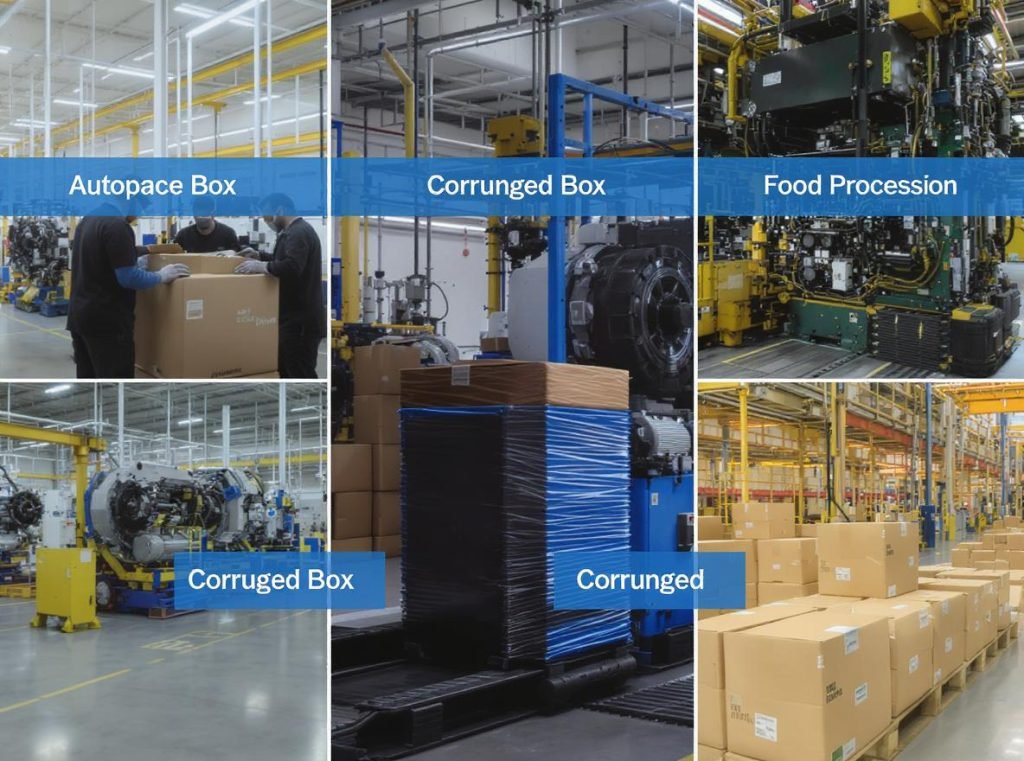

Triple wall boxes can be used for different packaging applications in industrial, aerospace, appliance, automotive, food and beverage, chemical, construction, electronics, medical, paper and transportation markets. This versatility makes them valuable across numerous industries.

How Do Triple Wall Boxes Perform in Export and International Shipping?

International shipping presents unique challenges that require the strongest packaging solutions available.

Triple wall corrugated boxes excel in export shipping as a fumigation-free alternative to wooden crates. They’re 250% lighter than wood crates, provide 22% average cost savings, and eliminate customs delays since they’re exempt from ISPM 15 heat treatment requirements. Their durability withstands multiple handling points, extended transit times, and rough treatment common in international logistics.

The fumigation-free advantage is particularly valuable for international shipping. Unlike wooden crates that require ISPM 15 heat treatment or fumigation certificates, triple wall corrugated boxes can be exported without these costly and time-consuming processes. This eliminates customs delays and reduces overall shipping complexity.

Weight reduction provides immediate cost benefits. Triple wall boxes are 250% lighter than equivalent wooden crates, translating to significant savings in air freight where weight charges are substantial. Ocean freight also benefits from improved container utilization and reduced handling costs.

International logistics present specific challenges where triple wall boxes shine:

- Multiple Handling Points: Products get loaded and unloaded numerous times

- Extended Transit Times: Longer exposure to environmental stresses

- Customs Inspections: Additional opening and resealing of packages

- Stacking Requirements: Containers require maximum stacking strength

If you need packaging for export or other industrial applications, triple wall boxes are the strongest and most durable form of corrugated packaging. They maintain structural integrity throughout the entire shipping process.

Weather resistance is another critical factor. While not completely waterproof, triple wall construction provides better moisture resistance than thinner alternatives. Some manufacturers offer weatherproof eco-board options for enhanced protection in humid conditions.

What Are the Cost Benefits of Using Triple Wall Corrugated Boxes?

Smart packaging choices can significantly impact your bottom line through reduced damage claims and improved efficiency.

Triple wall corrugated boxes offer substantial cost savings with 40-60% lower material costs compared to wooden crates, 75% weight reduction for shipping savings, and elimination of wood packaging regulations for international shipping. They significantly decrease product damage rates, saving money on replacements and returns while providing flat-pack shipping efficiency.

The global triple wall corrugated paperboard market was valued at approximately $8.5 billion in 2022, with an expected compound annual growth rate (CAGR) of 5.7% through 2030. This growth reflects increasing recognition of cost benefits across industries.

Direct cost comparisons show clear advantages:

- Material costs: 40-60% less expensive than equivalent wood crates

- Shipping weight: Up to 75% lighter than wooden alternatives

- Labor efficiency: Faster assembly and packing processes

- Storage space: Flat-pack shipping reduces warehouse requirements

Triple wall boxes are made from recyclable materials, making them eco-friendly and cost-effective. This environmental benefit increasingly matters to customers and can support sustainability marketing efforts.

International shipping regulations favor corrugated packaging. Wood packaging requires fumigation certificates and special treatments for many countries, adding time and cost to export processes. Triple wall boxes eliminate these regulatory hurdles.

Storage efficiency also improves costs. These boxes can be shipped flat and assembled as needed, reducing warehouse space requirements compared to storing rigid wooden crates.

Which Industries Benefit Most from Triple Wall Corrugated Packaging?

Different industries have specific packaging needs that make triple wall boxes particularly valuable.

Manufacturing, automotive, electronics, aerospace, food processing, and appliance industries benefit most from triple wall corrugated packaging. The automotive sector uses them extensively for engine components, body panels, and aftermarket parts. Electronics manufacturers rely on them for large appliances, industrial electronics, and precision instruments weighing 121-300 pounds.

Manufacturing companies use triple wall boxes extensively for several applications. Raw materials often arrive in bulk quantities requiring sturdy containers. Finished products, especially industrial equipment, need protection during distribution to customers worldwide.

The aerospace industry has stringent packaging requirements due to the critical nature of components. Triple wall boxes are used in aerospace applications where even minor damage can have serious consequences. These boxes provide the reliability needed for aircraft parts and ground support equipment.

Food processing companies rely on triple wall packaging for different reasons:

- Bulk Ingredients: Large quantities of ingredients need sturdy containers

- Processing Equipment: Heavy machinery requires secure packaging

- Export Requirements: International food shipments need robust protection

- Temperature Resistance: Better performance in cold storage environments

Construction companies appreciate triple wall boxes for tools, hardware, and building materials. The durability matches the demanding construction environment where packages might be stored outdoors or in harsh conditions.

Medical device manufacturers choose triple wall packaging for expensive diagnostic equipment and surgical instruments. The protection level ensures these precision devices arrive in perfect condition, maintaining their calibration and functionality.

How to Choose the Right Triple Wall Box Specifications for Your Needs?

Selecting the correct specifications ensures optimal protection while controlling costs effectively.

Choose triple wall box specifications based on your product weight, with ECT ratings of 90-112 for most heavy-duty applications. Standard specifications include 1100# burst strength for 280-300 pound capacity. Consider flute combinations like A/C/C for optimal strength-to-weight ratio, B/C/C for balanced performance, and custom features like moisture resistance or integrated handles.

ECT (Edge Crush Test) ratings indicate the box’s ability to withstand compression forces. Standard heavy-duty specifications include:

| ECT Rating | Burst Strength | Max Weight Capacity | Typical Applications |

|---|---|---|---|

| ECT-67 | 700# | 240 lbs | Medium-heavy items |

| ECT-80 | 900# | 260 lbs | Standard heavy-duty |

| ECT-90 | 1100# | 280 lbs | Industrial equipment |

| ECT-112 | 1300# | 300 lbs | Maximum capacity |

Box dimensions should allow for adequate cushioning material around your products. Leave 2-3 inches on all sides for protective inserts or padding. This space prevents damage from impacts and provides room for thermal expansion.

Consider special treatments based on your requirements:

- Moisture Resistance: Wax coating or special liners for humid conditions

- Print Quality: High-quality printing for branded packaging

- Handle Cutouts: For easier manual handling of heavy boxes

- Dividers: Internal compartments for multiple items

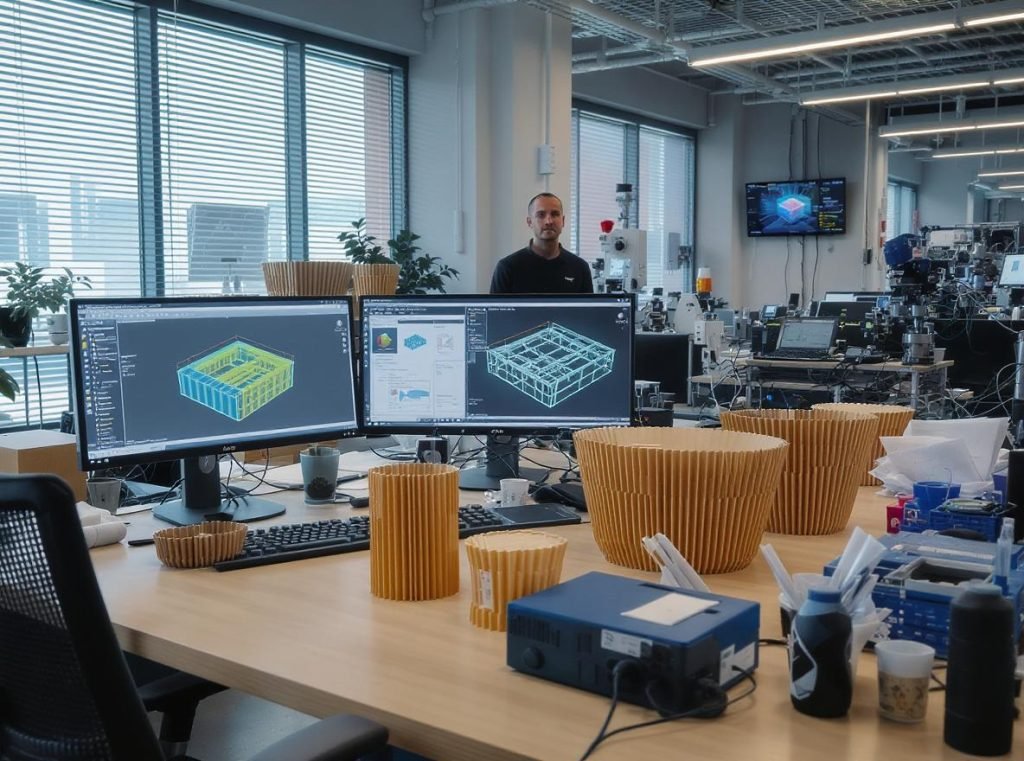

Working with experienced packaging suppliers helps optimize specifications. At Acreet, we analyze your specific products and shipping requirements to recommend the most cost-effective triple wall solutions that provide adequate protection without over-engineering.

What Are the Environmental Benefits of Triple Wall Corrugated Boxes?

Sustainability considerations increasingly influence packaging decisions across all industries.

Triple wall corrugated boxes offer exceptional environmental benefits with a 91% recycling rate – one of the most recycled materials globally. They’re 100% recyclable and can be recycled 5-7 times before fiber degradation. The corrugated industry achieved a 32% reduction in greenhouse gas emissions and 22% decrease in eutrophication effects, making them a sustainable packaging choice.

The corrugated industry leads in environmental performance with measurable improvements:

- 91% recycling rate: Highest among packaging materials

- 100% recyclable: Can be recycled 5-7 times before fiber degradation

- 32% reduction in greenhouse gas emissions (2006-2010)

- 22% decrease in eutrophication effects from improved manufacturing

- 14% reduction in respiratory impact from particulate matter

Triple wall boxes are made from renewable raw materials, predominantly fast-growing pine trees, and are completely biodegradable when recycling isn’t possible. The lighter weight also reduces transportation emissions compared to wooden alternatives.

FSC (Forest Stewardship Council) certification ensures that products come from responsibly managed forests that produce environmental, social and economic benefits. Many triple wall box manufacturers offer FSC-certified options, supporting responsible forest management practices.

Transportation efficiency contributes to environmental benefits. The lighter weight of corrugated boxes compared to wooden crates reduces fuel consumption during shipping. This weight savings translates to lower carbon emissions across your supply chain.

End-of-life disposal is significantly easier with corrugated packaging. While wooden crates might end up in landfills, corrugated boxes can be easily recycled through standard commercial recycling programs.

How to Optimize Triple Wall Box Design for Maximum Efficiency?

Proper design optimization ensures you get the best performance while controlling costs effectively.

Optimize triple wall box design through structural considerations like vertical flute orientation for maximum compression strength, proper flute combinations (A/C/C, B/C/C, A/A/A), and dimensional efficiency to minimize material waste. Include testing validation through Edge Crush Test (ECT), Box Compression Test (BCT), and Mullen Burst Test to ensure performance meets requirements.

Structural optimization principles include:

Flute Orientation: Vertical alignment provides maximum compression strength for stacking applications. Proper orientation can increase stacking strength by up to 40% compared to horizontal fluting.

Flute Combinations: Different combinations serve specific purposes:

- A/C/C: Optimal strength-to-weight ratio for most applications

- B/C/C: Balanced strength and printability for branded packaging

- A/A/A: Maximum thickness and cushioning for fragile items

Testing Validation: Critical testing methods ensure performance:

- Edge Crush Test (ECT): Measures vertical compression strength

- Box Compression Test (BCT): Evaluates stacking performance under load

- Mullen Burst Test: Determines puncture resistance and durability

Advanced design considerations include stress distribution for uniform load bearing, failure mode analysis to prevent catastrophic collapse, and material efficiency to achieve maximum strength-to-weight ratios.

Testing and validation should be part of your design process. ISTA (International Safe Transit Association) testing protocols help verify that your packaging will perform correctly under real shipping conditions.

Standardization across your product line can reduce costs. Using common box sizes for multiple products simplifies inventory management and often reduces per-unit costs through volume purchasing.

At Acreet, we work closely with customers to optimize their triple wall box designs. Our engineering team analyzes your products, shipping methods, and cost requirements to create packaging solutions that provide maximum protection at the lowest total cost.

Summary

Triple wall corrugated boxes represent the ultimate solution for heavy-duty packaging needs, offering strength comparable to wooden crates at significantly lower costs and environmental impact. From industrial machinery to export shipping, these boxes provide the protection, durability, and cost-effectiveness that modern businesses require.

Whether you’re shipping automotive parts, electronics, or bulk industrial products, triple wall packaging ensures your items arrive safely while supporting your sustainability goals and controlling shipping costs.

Ready to upgrade your packaging strategy? Contact Acreet today for custom triple wall corrugated box solutions designed specifically for your products and shipping requirements. Our packaging experts will help you select the right specifications, optimize your designs, and ensure maximum protection for your valuable shipments.