When shipping products globally, choosing the right packaging can make the difference between successful delivery and costly damages. Understanding cardboard box weight limits isn’t just about avoiding box failure—it’s about optimizing your shipping costs while ensuring your products arrive safely at their destination.

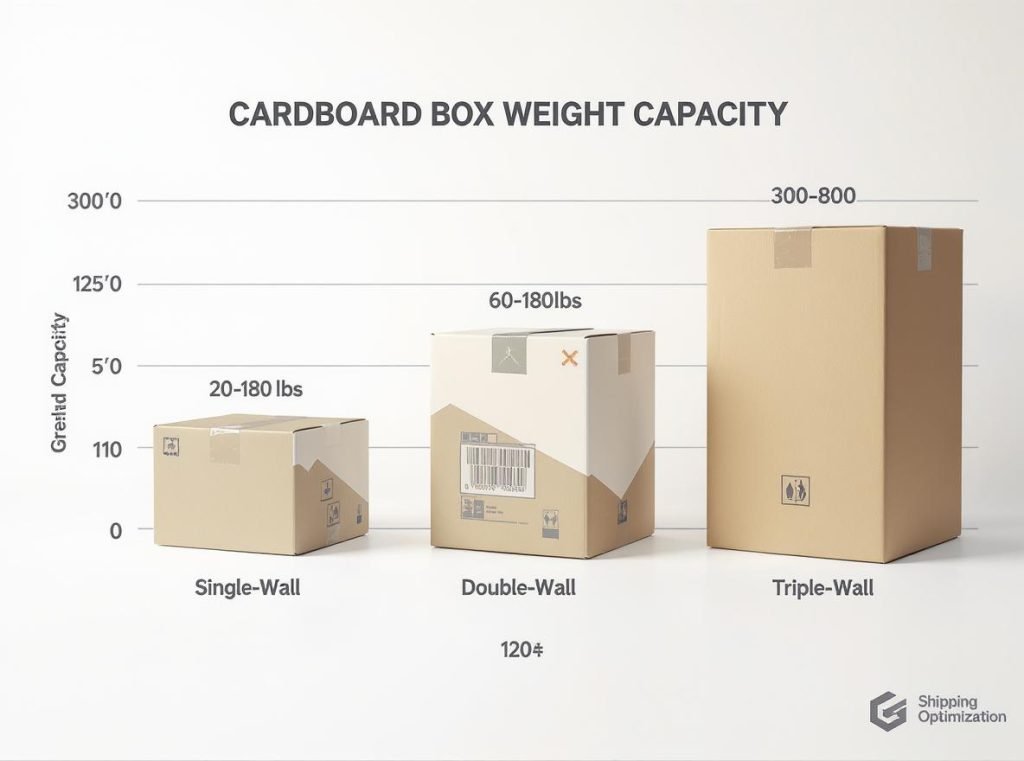

Different cardboard box grades have specific weight limits: single-wall boxes typically hold 20-120 pounds, double-wall boxes can handle 60-180 pounds, and triple-wall boxes support up to 300-800 pounds. These limits depend on factors like the box’s ECT rating, construction type, and environmental conditions.

Let’s explore the complete weight capacity guide to help you make informed packaging decisions for your business.

Table of Contents

ToggleWhat Determines a Cardboard Box’s Weight Capacity?

Understanding why different boxes have varying weight limits helps you choose the right packaging for your products. The strength of a cardboard box depends on several critical factors that work together to determine its overall capacity.

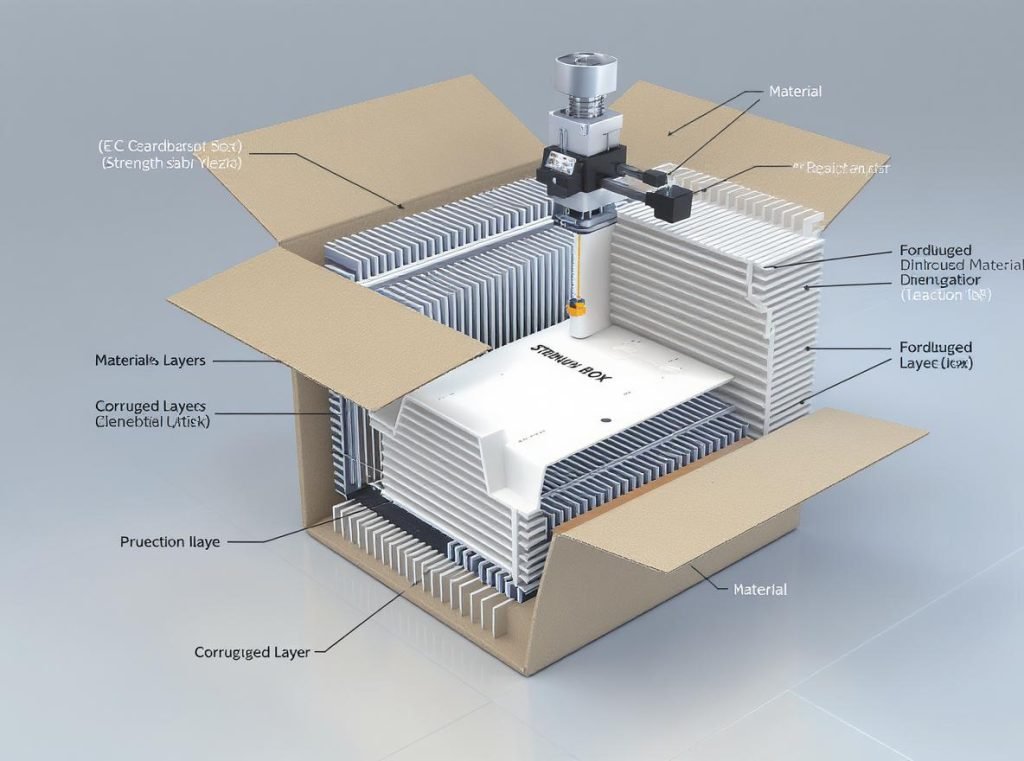

The weight capacity of cardboard boxes depends on four main factors: the corrugated board construction (single, double, or triple-wall), the ECT (Edge Crush Test) rating, material quality, and box design dimensions. These factors determine how much weight the box can safely hold without structural failure.

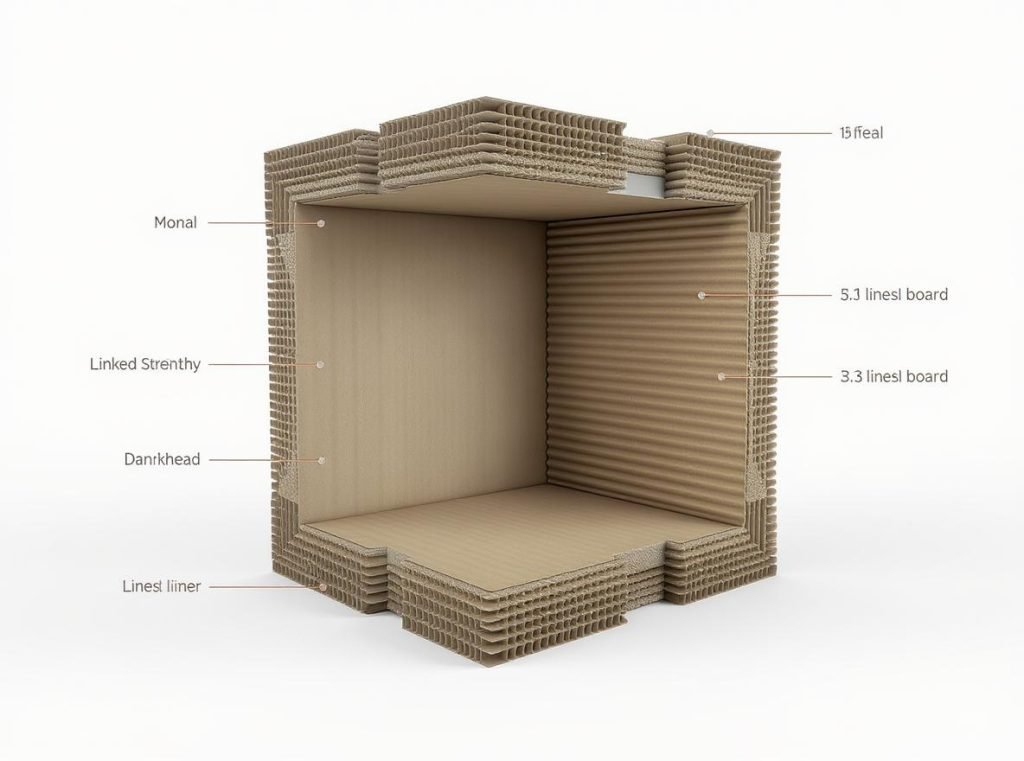

The construction of corrugated cardboard involves multiple layers of paper. Single-wall consists of one fluted layer between two flat liner boards, while double-wall adds another fluted layer for extra strength. Triple-wall construction provides the highest strength with three fluted layers and four liner boards.

Material composition plays a crucial role in determining weight capacity. The quality of raw materials, measured by basis weight and tightness, directly impacts the box’s compressive strength. Higher-grade materials with proper density provide better structural integrity.

Box design also influences weight capacity significantly. Square boxes generally offer better support than rectangular ones, while boxes with larger perimeters and greater heights typically have lower compressive strength. The perimeter-to-height ratio plays a crucial role in determining optimal load distribution.

The flute type and profile directly affect strength characteristics. A-flute provides maximum cushioning and stacking strength, while B-flute offers better crush resistance. C-flute strikes a balance between cushioning and structural integrity.

How Much Weight Can Single-Wall Cardboard Boxes Hold?

Single-wall corrugated boxes are the most common packaging solution for lightweight to medium-weight items. These boxes offer a good balance of cost-effectiveness and protection for many shipping applications.

Single-wall cardboard boxes typically hold between 20-120 pounds, depending on their ECT rating and construction quality. Standard 32 ECT boxes can safely hold up to 50 pounds, while higher-grade single-wall boxes with 44 ECT ratings can support up to 95 pounds.

Single-wall boxes are constructed with one fluted corrugated layer sandwiched between two flat liner boards. This construction provides adequate strength for most lightweight applications while maintaining cost-effectiveness.

The most common single-wall grades include:

| ECT Rating | Weight Limit | Mullen Rating | Best For |

|---|---|---|---|

| 29 ECT | Up to 40 lbs | 175# | Light products, clothing, documents |

| 32 ECT | Up to 50 lbs | 200# | Books, electronics, general merchandise |

| 44 ECT | Up to 95 lbs | 275# | Heavy items, tools, small appliances |

Single-wall boxes are ideal for shipping lightweight electronics, books, clothing, and retail products. They offer cost-effective packaging solutions while maintaining adequate protection for items that don’t require heavy-duty reinforcement.

When using single-wall boxes, proper packing techniques become essential. Distribute weight evenly throughout the box and use appropriate cushioning materials to prevent product movement. This helps maintain the box’s structural integrity throughout the shipping process.

What Are the Weight Limits for Double-Wall Cardboard Boxes?

Double-wall corrugated boxes provide significantly more strength and durability than single-wall alternatives. These boxes feature two layers of fluted corrugated material with three liner boards, making them ideal for heavier products and longer shipping distances.

Double-wall cardboard boxes can typically hold between 60-180 pounds, with standard grades starting at 44-48 ECT supporting up to 100 pounds. The additional corrugated layer provides superior protection against impact and compression forces.

Double-wall boxes feature two corrugated layers with three liner boards, providing significantly enhanced strength. The dual-layer design offers better cushioning and structural integrity for valuable or fragile items requiring extra protection during transit.

Double-wall construction is recommended for heavy machinery, appliances, furniture, and bulk shipping applications. The enhanced strength comes from the layered construction, which provides better compression resistance and impact protection.

Common double-wall specifications include:

- 44 ECT rating: Supports up to 80 pounds

- 48 ECT rating: Handles up to 100 pounds

- 51 ECT rating: Can support up to 125 pounds

Double-wall boxes excel in several scenarios: international shipping where packages face multiple handling points, heavy products like machinery parts or automotive components, fragile items requiring extra protection, and long-distance shipping where boxes may be stored for extended periods.

The investment in double-wall construction often pays for itself through reduced damage claims and improved customer satisfaction. For businesses shipping valuable or heavy products, double-wall boxes provide the peace of mind that comes with superior protection.

When Should You Use Triple-Wall Cardboard Boxes?

Triple-wall corrugated boxes represent the strongest standard cardboard packaging available. These boxes feature three layers of fluted corrugated material with four liner boards, providing exceptional strength for the heaviest and most demanding shipping applications.

Triple-wall cardboard boxes can hold between 300-800 pounds while maintaining structural integrity. With ECT ratings ranging from 60-90, these boxes are designed for industrial applications, heavy machinery, and situations where wooden crates might otherwise be necessary.

Triple-wall boxes represent the strongest standard corrugated construction available. Some industrial applications report triple-wall boxes handling up to 500 kg (1,100 pounds) under optimal conditions.

The multiple layers provide excellent compression strength, making them suitable for stacking heavy items. They also offer superior puncture resistance and can withstand rough handling throughout the shipping process.

Common applications for triple-wall boxes include:

- Industrial equipment and machinery

- Heavy automotive parts and components

- Large electronic equipment and appliances

- Bulk shipments of dense products

- Export shipping where maximum durability is critical

Triple-wall boxes provide compression strength comparable to wooden crates while maintaining lighter weight and better cost-effectiveness. They’re essential for industrial equipment, machinery, and heavy-duty storage applications.

When using triple-wall boxes, proper handling equipment becomes important. The boxes themselves can be quite heavy even when empty, so ensure your staff has the tools and training necessary to handle them safely.

How Do ECT and Mullen Test Ratings Affect Weight Limits?

Understanding testing standards helps you make informed decisions about packaging strength. Two primary tests determine cardboard box ratings: the Edge Crush Test (ECT) and the Mullen Burst Test, each measuring different aspects of box strength.

The ECT rating measures stacking strength and determines how much weight can be placed on top of a box before it crushes. ECT provides a more accurate predictor of real-world performance, with ratings directly correlating to safe weight limits. Higher ECT ratings indicate stronger boxes with higher weight capacities.

The Edge Crush Test measures the compressive strength of corrugated board by applying force perpendicular to the fluted edge. This test directly relates to a box’s stacking strength and ability to withstand vertical compression during shipping and storage.

ECT ratings are expressed in pounds per linear inch and directly correlate with weight capacity. Common ECT ratings and their corresponding weight limits include:

| ECT Rating | Weight Capacity | Typical Construction |

|---|---|---|

| 29 ECT | Up to 40 pounds | Single-wall, light duty |

| 32 ECT | Up to 50 pounds | Single-wall, standard |

| 44 ECT | Up to 95 pounds | Single-wall, heavy duty |

| 48 ECT | Up to 100 pounds | Double-wall, standard |

| 55+ ECT | 50+ kg (110+ lbs) | Double/triple-wall, heavy duty |

The Mullen Burst Test measures the force required to rupture the face of corrugated board. This test evaluates a box’s resistance to punctures and rough handling rather than compression strength. Mullen ratings are expressed in pounds per square inch (psi).

Modern packaging standards increasingly favor ECT ratings because they better predict real-world performance. ECT testing more accurately reflects how boxes perform when stacked in warehouses and during shipping, making it more relevant for palletized shipping applications.

What Environmental Factors Can Reduce Box Weight Capacity?

Even high-quality cardboard boxes can lose strength under certain conditions. Understanding these factors helps you maintain packaging integrity and avoid costly shipping failures.

Environmental conditions significantly impact box strength, with humidity being the most critical factor. High humidity can reduce cardboard strength by up to 50%, while temperature extremes and physical damage can cause additional strength reduction even within rated weight limits.

Moisture content is the most critical factor affecting box strength. High humidity causes wood fibers in cardboard to absorb moisture, directly weakening the material structure. Research shows specific humidity impacts on strength:

- 50% relative humidity: Maintains original strength

- 65% relative humidity: Reduces strength to 80% of original

- 80% relative humidity: Reduces strength to 60% of original

- 95% relative humidity: Can reduce strength by up to 59% after four days

Temperature extremes also affect box performance. Very cold temperatures can make cardboard brittle, while excessive heat can weaken adhesives. Direct sunlight exposure causes photodegradation, weakening the physical structure and causing color fading.

Physical damage significantly impacts box strength:

- Printing and perforations reduce strength by creating weak points

- Large openings or handle holes decrease compression resistance

- Improper handling during assembly can reduce strength by up to 30%

- Previous moisture exposure can permanently weaken fiber bonds

Storage conditions play a crucial role in maintaining box strength. Store boxes in dry, climate-controlled environments below 50% relative humidity. Avoid direct contact with concrete floors and keep boxes away from heat sources and direct sunlight.

How Do International Shipping Requirements Affect Box Selection?

International shipping presents unique challenges that require careful consideration of box strength and durability. Understanding these requirements helps ensure your packages arrive safely at their global destinations.

International shipping requires stronger boxes due to extended transit times, multiple handling points, and varying environmental conditions. Double-wall construction with higher ECT ratings is typically recommended for international shipments, even for products that might use single-wall boxes domestically.

International shipments face more handling than domestic packages. Your box might pass through multiple sorting facilities, customs inspections, and various transportation methods. Each handling point increases the risk of damage, making stronger packaging essential.

Different countries have varied regulations concerning packaging materials and construction standards. International shipments must comply with destination country requirements for materials, labeling, and documentation to avoid customs delays or rejections.

Corrugated cardboard boxes are preferred for international shipping due to their superior durability and strength. International packages face longer transit times and multiple handling points, requiring boxes that can withstand extended stress.

Specific international shipping guidelines include:

- Double-wall boxes recommended for shipments exceeding 30 kg

- Continental US shipments require minimum 4 inches of protective padding

- Outside continental US shipments need 6 inches of padding

- International packages should be slightly larger than contents for proper cushioning

Climate variations during international transit can stress packaging materials. Shipments might experience tropical humidity, desert heat, or arctic cold conditions. Boxes must maintain their strength across these environmental extremes.

Working with experienced international shipping partners helps navigate these complexities. They can provide guidance on optimal packaging for specific destinations and shipping methods.

What Are the Best Practices for Maximizing Box Strength?

Proper packing techniques can help you achieve maximum performance from your cardboard boxes. Following these best practices ensures your packages arrive safely while optimizing your packaging costs.

Maximize box strength by using proper sealing techniques, distributing weight evenly, and selecting appropriate box sizes. High-quality packaging tape applied in H-pattern, adequate cushioning materials, and proper loading techniques can significantly enhance packaging performance.

Proper sealing techniques directly impact box strength. Use high-quality packaging tape at least 48mm wide applied in three layers across the entire box length. The H-tape method provides optimal security by sealing the center seam and both edges, creating an H-pattern for maximum reinforcement.

Water-activated tape offers superior bonding strength and tamper-evident properties, while filament tape provides extra reinforcement for heavy-duty applications. Avoid masking tape, cellophane tape, or duct tape, which lack proper adhesion to corrugated surfaces.

Structural reinforcement techniques include:

- Tape all inside joints and edges to reinforce critical stress points

- Double boxing can nearly double strength capacity when identical-sized boxes are available

- Reinforce corners and bottom with additional cardboard pieces

- Add cardboard base layers to distribute weight more effectively

Weight distribution represents the most critical factor in box performance. Place heavier items at the bottom center of the box and surround them with lighter items. This prevents the box from becoming top-heavy and reduces stress on the bottom panel.

Use adequate cushioning materials to fill void spaces and prevent contents from shifting during transit. Proper cushioning helps maintain box shape and distributes forces throughout the package.

Environmental protection measures include storing boxes in controlled environments with relative humidity below 50% to maintain optimal strength. Avoid direct sunlight exposure and extreme temperature variations that can weaken materials.

Professional packaging optimization includes testing your packaging with sample shipments before full-scale implementation, training staff on proper packing techniques, and monitoring damage rates to adjust packaging as needed.

Summary

Understanding cardboard box weight limits ensures successful shipping and protects your business reputation. Single-wall boxes handle 20-120 pounds, double-wall boxes support 60-180 pounds, and triple-wall boxes can carry up to 300-800 pounds. Environmental factors like humidity can reduce strength by up to 50%, making proper storage and handling essential.

Ready to optimize your packaging solution? Contact Acreet’s packaging experts today for custom box designs that perfectly match your weight requirements and shipping needs. Our team specializes in creating durable packaging solutions for international shipping, helping you avoid damage claims while minimizing costs. Send us your product specifications and shipping requirements for a personalized packaging consultation that ensures your products arrive safely worldwide.