Sourcing packaging from Chinese suppliers without proper certifications is like buying insurance after the accident. With over 70% of customers requesting proof of certifications before finalizing partnerships, the wrong choice could lock you out of major contracts and expose your brand to costly recalls and regulatory violations.

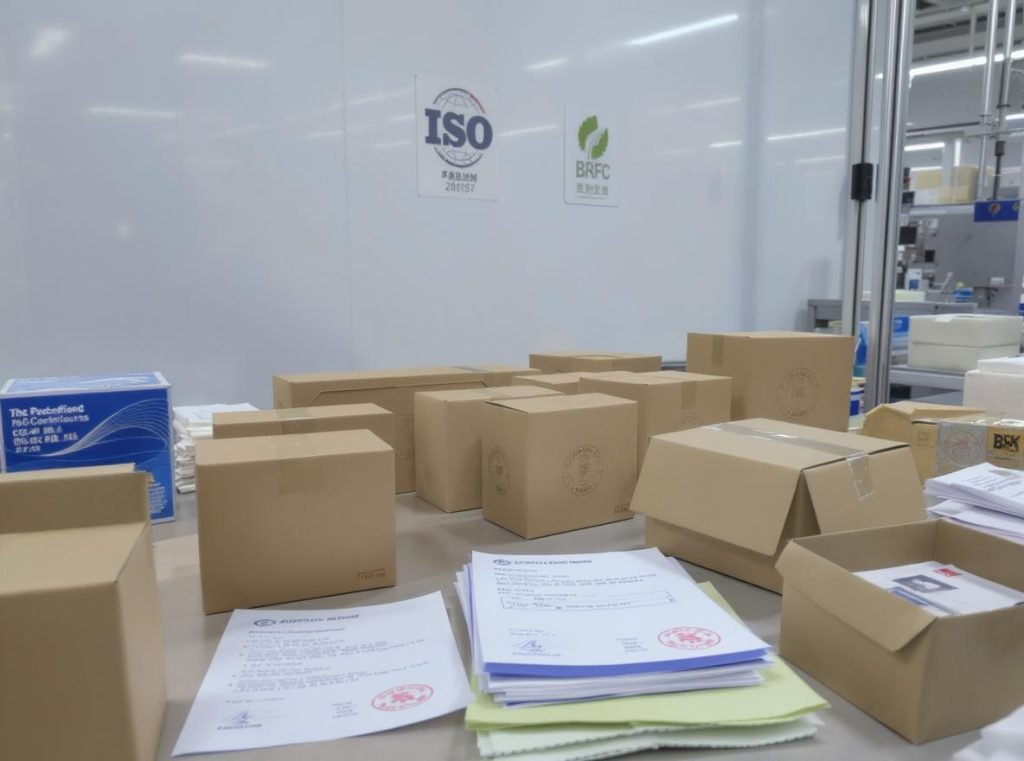

The most critical certifications to look for in a Chinese packaging supplier include ISO 9001 (Quality Management), BRC/BRCGS Packaging Materials, ISO 14001 (Environmental Management), FSSC 22000 (Food Safety), and industry-specific standards like ISO 15378 for pharmaceuticals. These certifications ensure your supplier maintains international standards for quality, safety, and regulatory compliance while protecting your brand reputation.

Understanding these certifications isn’t just about compliance – it’s about building partnerships that deliver consistent quality, reduce risks, and open doors to global markets. Let’s explore what each certification means and why they’re essential for your packaging supply chain success.

Table of Contents

ToggleWhy Do Certifications Matter When Choosing a Chinese Packaging Supplier?

Large companies consistently require specific certifications from their suppliers, and without proper credentials, suppliers often cannot even be considered for major contracts.

Certifications serve as fundamental indicators of quality, safety, and regulatory compliance that protect your brand from costly recalls, regulatory violations, and quality issues while ensuring your packaging meets international standards. They provide tangible benefits including enhanced regulatory compliance, improved product safety, competitive market positioning, and sustained time and cost savings.

Beyond meeting customer requirements, certifications demonstrate a supplier’s commitment to quality, environmental responsibility, and operational excellence. They act as a universal language of quality that transcends cultural and language barriers, making supplier evaluation more objective and reliable.

The business impact is significant:

- Risk reduction through proven quality management systems

- Regulatory compliance ensuring smooth customs clearance

- Market access to customers who mandate certified suppliers

- Brand protection through consistent product quality

- Cost savings from reduced defects and returns

For international buyers, certifications level the playing field by providing standardized benchmarks for supplier evaluation. They offer peace of mind that your chosen supplier operates according to globally recognized best practices.

What Is ISO 9001 and Why Is It Essential for Packaging Suppliers?

ISO 9001 certification is the cornerstone of quality assurance in packaging manufacturing and should be your first checkpoint when evaluating any Chinese supplier.

ISO 9001:2015 is a globally recognized standard that demonstrates suppliers operate a fully integrated quality management system and can consistently provide high-quality services. This certification ensures consistency in production, improved customer satisfaction, and continuous operational improvement through eight key quality management principles.

The standard focuses on critical areas that directly impact your packaging quality:

- Customer focus ensuring your requirements are understood and met

- Leadership commitment from senior management

- Process approach for consistent, efficient operations

- Continual improvement through regular system reviews

- Factual approach to decision-making based on data analysis

Implementation requirements include comprehensive documentation of internal processes, procedures, and standards, followed by rigorous third-party audits against ISO 9001 requirements. Suppliers must undergo re-certification every three years with annual surveillance audits to maintain their status.

| Quality Benefit | Without ISO 9001 | With ISO 9001 |

|---|---|---|

| Defect Prevention | Reactive approach | Proactive systems |

| Process Control | Inconsistent methods | Standardized procedures |

| Customer Satisfaction | Variable results | Consistent improvement |

| Delivery Reliability | Unpredictable schedules | Systematic planning |

| Corrective Actions | Ad-hoc responses | Structured problem-solving |

The certification process involves initial assessment, gap analysis, system implementation, and final audit. Once certified, suppliers demonstrate their ability to deliver consistent quality while continuously improving their operations.

What Are BRC/BRCGS Packaging Standards and When Do You Need Them?

The BRC Global Standard for Packaging Materials is the first packaging standard recognized by the Global Food Safety Initiative (GFSI) and has become the global industry benchmark for packaging excellence.

BRCGS Packaging Materials certification is essential for suppliers serving the food, beverage, and consumer goods industries. Currently in its 7th issue, this standard provides protection for consumers across all supply chain levels and demonstrates compliance with rigorous requirements including hazard management systems, senior management commitment, and quality management systems.

The standard applies to various operations:

- Production of packaging materials for conversion or printing

- Supply of materials from stock where additional processing occurs

- Manufacturing of unconverted or semi-converted materials

- Various materials including glass, paper, metal, plastics, and other trade products

BRCGS certification covers critical areas that directly impact food safety:

- Hazard analysis and risk assessment procedures

- Senior management commitment to food safety

- Quality management systems integration

- Prerequisite programs covering basic environmental and operational conditions

- Supplier approval and monitoring systems

The audit process typically requires 1.5 days on-site with additional time for report writing and corrective action management. Suppliers receive grades ranging from AA (excellent) to D (major non-conformances), with most customers requiring at least a B grade for approval.

This certification is particularly crucial if you’re targeting:

- Major food and beverage manufacturers

- Retail private label suppliers

- Export markets with strict food safety requirements

- Customers with GFSI-recognized certification requirements

How Important Are Environmental Certifications Like ISO 14001?

Environmental responsibility has evolved from a nice-to-have to a business requirement, with 73% of global consumers willing to adjust purchasing habits for sustainability and 41% willing to pay premiums for credible eco-labels.

ISO 14001 certification confirms a company’s voluntary adoption of an environmental management system designed to minimize negative environmental impacts and promote continuous improvement. This certification is particularly relevant for packaging manufacturers where production processes can have significant environmental footprints.

The standard requires comprehensive environmental management including:

- Environmental analysis to identify aspects and impacts

- Establishment of environmental policies with concrete improvement commitments

- Implementation of structured environmental management programs

- Regular monitoring and measurement of environmental performance

- Continuous improvement through management review processes

For packaging suppliers, this translates to:

- Adoption of sustainable materials and eco-friendly packaging methods

- Waste reduction and improved recycling programs

- Energy efficiency improvements and carbon footprint reduction

- Water conservation and pollution prevention measures

- Sustainable sourcing practices for raw materials

Additional environmental certifications gaining importance include:

- FSC (Forest Stewardship Council) for responsible forestry practices

- PEFC for sustainable forest management

- Cradle to Cradle for circular design principles

- Various compostability standards like BPI certification

| Environmental Aspect | Business Impact | Customer Benefit |

|---|---|---|

| Sustainable Materials | Meets regulatory requirements | Supports brand sustainability goals |

| Waste Reduction | Lower operational costs | Reduced environmental impact |

| Energy Efficiency | Competitive pricing | Lower carbon footprint |

| Water Conservation | Regulatory compliance | Environmental responsibility |

| Recycling Programs | Material cost savings | Circular economy support |

What Food Safety Certifications Should You Require?

If your packaging will contact food products, food safety certifications aren’t optional – they’re mandatory for legal compliance and consumer protection.

FSSC 22000 provides a comprehensive certification scheme for food packaging manufacturers, incorporating in-depth hazard analysis into robust Food Safety Management Systems. This GFSI-recognized standard is specifically designed for packaging manufacturers and combines ISO 22000 with sector-specific requirements.

The certification covers primary and secondary food packaging materials including:

- Flexible and rigid plastics for food contact

- Paper products including cartons and wrapping materials

- Metal containers and closures

- Glass jars and bottles

- Composite materials and multi-layer packaging

FSSC 22000 requires implementation of critical food safety elements:

- HACCP (Hazard Analysis Critical Control Points) systems

- Good Manufacturing Practices (GMP)

- Contamination control measures and prevention programs

- Supplier approval and monitoring systems

- Traceability systems for all raw materials

Safe Quality Food (SQF) certification ensures packaging suppliers meet the highest global food safety standards through rigorous third-party audits. This certification is particularly important for suppliers serving the North American food industry, as it demonstrates adherence to strict hygiene and safety protocols.

Key requirements for food safety certification include:

- Clean room manufacturing environments for food contact materials

- Regular migration testing for chemical safety

- Comprehensive pest control programs

- Staff training on food safety protocols

- Documentation and record-keeping systems

Without proper food safety certifications, your products risk:

- Customs rejection and import delays

- Mandatory product recalls and liability issues

- Loss of major retail and food service customers

- Regulatory penalties and compliance violations

- Permanent damage to brand reputation

Are There Industry-Specific Certifications You Should Know About?

Different industries have unique requirements, and specialized certifications ensure your packaging supplier can meet these specific regulatory and quality standards.

Industry-specific certifications like ISO 15378 for pharmaceutical packaging, CCAP for automotive products, and CCC for electronics are crucial depending on your market sector. These certifications address specialized requirements that general quality standards don’t cover.

For pharmaceutical packaging, ISO 15378 certification is essential:

- Establishes conditions and Good Manufacturing Practices for pharmaceutical packaging

- Ensures patient safety through contamination control measures

- Requires validation of all packaging processes and materials

- Mandates comprehensive traceability for pharmaceutical supply chains

- Covers primary packaging materials that contact medicinal products directly

Automotive industry requirements include:

- CCAP (Certification Centre for Automotive Products) for Chinese automotive market compliance

- Technical regulation compliance for automotive packaging components

- Quality standards specific to automotive supply chains

- Environmental and safety requirements for automotive materials

Electronics and technology sectors require:

- CCC (China Compulsory Certification) for products entering Chinese markets

- Electronic component packaging standards

- Anti-static and protective packaging requirements

- Compliance with electronic waste regulations

Sustainable packaging certifications are increasingly important:

- FSC certification for responsible forestry practices

- Recycling and compostability standards

- Carbon footprint reduction certifications

- Sustainable sourcing verification programs

| Industry | Key Certification | Primary Focus | Business Impact |

|---|---|---|---|

| Pharmaceutical | ISO 15378 | Patient safety, contamination control | Regulatory compliance, market access |

| Food & Beverage | FSSC 22000, BRCGS | Food safety, hygiene | Consumer protection, brand reputation |

| Automotive | CCAP, ISO/TS 16949 | Quality, safety standards | Supply chain qualification |

| Electronics | CCC, IPC standards | Product safety, performance | Market entry, compliance |

| Cosmetics | ISO 22716 | Good manufacturing practices | Quality assurance, regulatory approval |

How Can You Verify the Authenticity of Certifications?

Certificate fraud is unfortunately common in global supply chains, making verification crucial for protecting your business from unqualified suppliers and potential compliance violations.

Authentic certification verification requires cross-referencing certificate numbers with official certification body databases, verifying certification body accreditation through recognized organizations, checking certificate validity dates, and contacting certification bodies directly to confirm authenticity.

Modern certificates often include security features that enable easy verification:

- QR codes linking to official certification databases

- Watermarks and security printing features

- Unique serial numbers for tracking

- Digital signatures from certification bodies

- Holographic elements for tamper detection

Essential verification steps include:

Contact certification bodies directly using information from their official websites, not from the certificates themselves. Most reputable certification bodies maintain online databases where certificate authenticity can be verified immediately.

Review detailed audit reports, not just certificates. These reports provide insight into the supplier’s actual performance, any areas of concern identified during audits, and corrective actions taken to address non-conformances.

Verify the scope of certification matches your specific requirements. Certificates should clearly state which products, processes, and locations are covered by the certification.

Red flags that indicate potential certificate fraud:

- Certificates that appear photocopied or digitally altered

- Certification bodies with no verifiable online presence

- Certificates without specific scope definitions or limitations

- Expired certificates or those nearing expiration

- Certificates that don’t match the supplier’s actual capabilities

Best practices for verification:

- Always request original certificates with security features

- Cross-reference multiple sources for certification body legitimacy

- Verify that certificates cover the specific manufacturing locations you’ll use

- Check that certification scope includes your specific packaging requirements

- Confirm that certificates are current and have proper renewal schedules

What Questions Should You Ask Potential Suppliers About Their Certifications?

The right questions reveal whether suppliers truly understand and implement their certified systems or simply maintain certificates for marketing purposes.

Ask specific questions about certification scope, audit results, continuous improvement processes, and how certifications impact daily operations. Focus on understanding implementation depth rather than just certificate possession.

Quality management questions:

“Can you walk me through your ISO 9001 customer complaint handling process?” This reveals whether they actually use their quality management system effectively or just maintain it for compliance purposes.

“What specific improvements have you made based on your last ISO audit findings?” This demonstrates their commitment to continuous improvement and transparency about areas needing attention.

“How do you ensure all production staff understand and follow your certified procedures?” This indicates whether certification is truly integrated into daily operations or exists only on paper.

Food safety and BRC-specific questions:

“What grade did you achieve in your most recent BRCGS audit, and what were the key findings?” This shows their performance level and willingness to discuss areas for improvement.

“How do you handle contamination prevention in your manufacturing environment?” This reveals their understanding of food safety principles and practical implementation.

“Can you provide documentation proving your packaging materials meet food contact safety requirements?” This ensures they can provide necessary regulatory compliance documentation.

Environmental and sustainability questions:

“What specific environmental improvements have you achieved through your ISO 14001 system?” This demonstrates real implementation rather than just compliance.

“How do you manage sustainable sourcing for your raw materials?” This shows their commitment to environmental responsibility throughout their supply chain.

“What waste reduction or energy efficiency measures have you implemented?” This reveals practical environmental management beyond basic compliance.

Industry-specific questions:

“How do you ensure your pharmaceutical packaging meets contamination control requirements?” This tests their understanding of specialized industry needs.

“What validation procedures do you follow for new packaging materials?” This shows their commitment to product safety and regulatory compliance.

Warning signs in supplier responses:

- Vague or evasive answers about certification implementation details

- Inability to provide specific examples of system benefits or improvements

- Reluctance to share audit reports or detailed documentation

- Lack of knowledge about certification requirements and standards

- Focus on certificates rather than actual operational practices

How Do Certifications Impact Pricing and Lead Times?

Understanding the financial implications of certifications helps you make informed decisions about supplier selection and budget planning while recognizing the long-term value they provide.

Certifications can significantly impact both pricing and lead times. Sustainable packaging certifications can cost $5,000 to $50,000 or more per product line, and certified materials generally cost more than non-certified alternatives due to extra testing, audits, and licensing requirements. However, these costs are often offset by reduced risk of recalls, improved market access, and enhanced brand reputation.

Cost structure analysis:

Certification maintenance requires ongoing investment in surveillance audits, system updates, and staff training. Most certifications require annual surveillance audits with full re-certification every three years, representing continuous operational expenses.

The certification process itself varies by standard but typically involves documentation preparation, pre-assessment, testing and validation, and final audit phases. BRCGS audits require approximately 1.5 days on-site, while ISO certifications may take several weeks to complete depending on organizational readiness.

Lead time considerations:

- Initial supplier qualification takes longer due to documentation requirements

- Certification requirements can extend project timelines, particularly for new product launches

- Quality control processes may add 1-2 days to standard production schedules

- However, certified suppliers typically provide more predictable delivery schedules

| Certification Level | Price Premium | Quality Benefits | Delivery Reliability |

|---|---|---|---|

| No Certification | Baseline pricing | Variable quality, higher defect rates | 70-80% on-time delivery |

| Basic Certifications | +10-15% | Improved consistency, lower defects | 85-90% on-time delivery |

| Comprehensive Certifications | +15-25% | Excellent quality, minimal defects | 95%+ on-time delivery |

Total cost of ownership analysis:

- Reduced inspection and testing costs due to supplier reliability

- Lower warranty and return costs from improved quality

- Avoided costs from regulatory compliance issues and recalls

- Improved customer satisfaction and retention rates

- Enhanced market access and competitive positioning

Value proposition considerations:

While certified suppliers may charge premium prices, they deliver superior value through reduced risks, improved quality, and enhanced market access. The investment in certified suppliers often pays for itself through avoided problems and improved business outcomes.

Summary

Selecting properly certified Chinese packaging suppliers is essential for ensuring quality, safety, and regulatory compliance in today’s global marketplace. Focus on core certifications like ISO 9001 for quality management and BRC/BRCGS for food safety, while considering industry-specific requirements and environmental standards based on your market needs. Remember that certifications represent genuine commitments to operational excellence – verify authenticity, ask detailed implementation questions, and understand the value they bring to your supply chain success.

Ready to source certified packaging solutions that protect your brand and meet international standards? Contact Acreet today for expert guidance on selecting the right certified suppliers for your packaging needs. Our experienced team can help you navigate certification requirements and connect you with verified, certified manufacturers who deliver the quality and reliability your business demands.