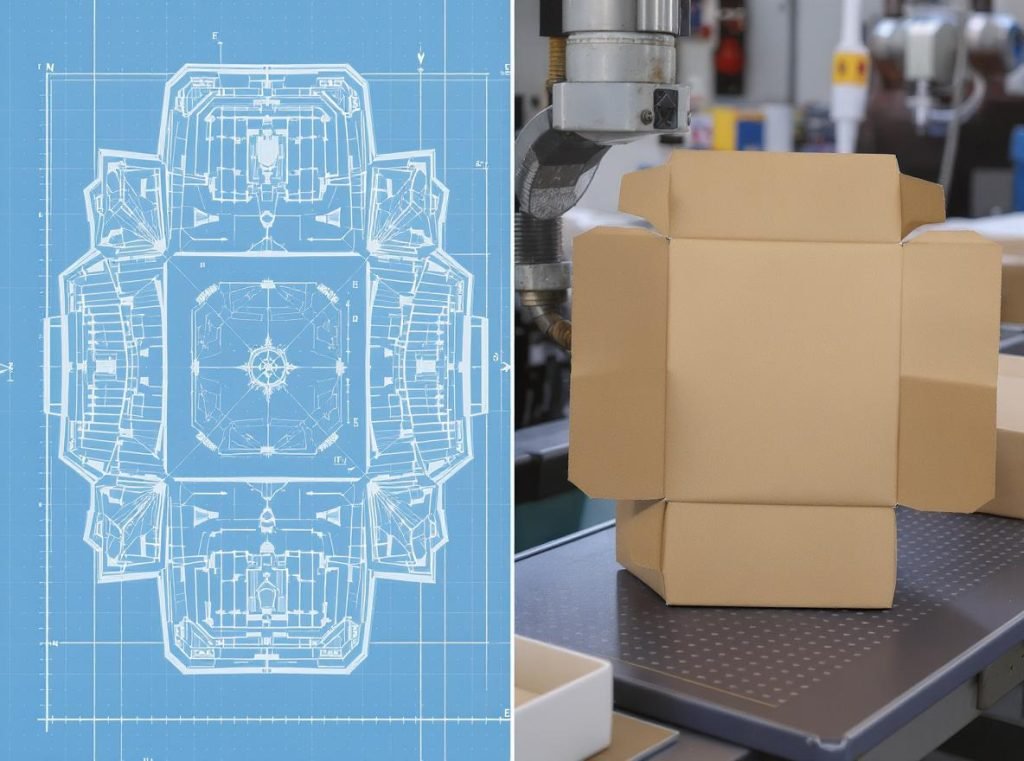

When you’re planning custom packaging for your business, one crucial element can make or break your entire production process. Without it, you’ll face costly errors, wasted materials, and disappointed customers. That element is a dieline – and understanding it could save you thousands.

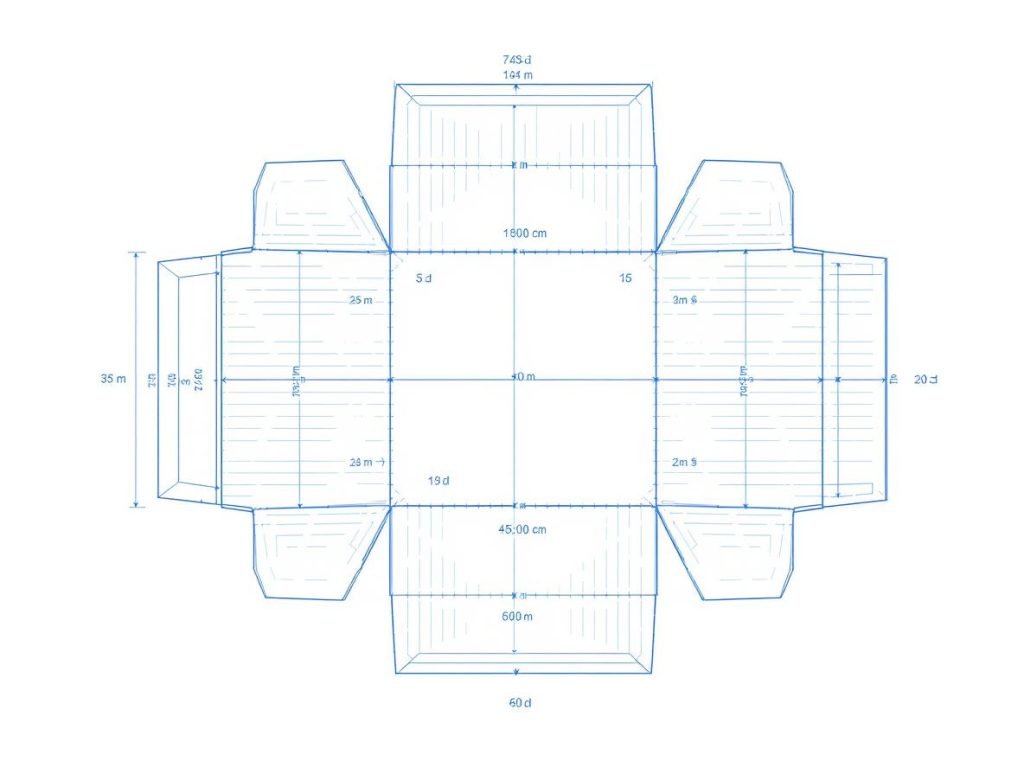

A dieline is a two-dimensional technical diagram that serves as the blueprint for all packaging production. It’s essentially a flattened template that shows exactly where a package will be cut, folded, and assembled, acting as a universal language between designers, manufacturers, and printers to ensure everyone understands how the final package should be constructed.

Ready to discover why dielines are the foundation of successful custom packaging? Let’s explore everything you need to know.

Table of Contents

ToggleWhat Exactly is a Dieline in Packaging?

Understanding dielines is crucial for anyone involved in custom packaging production. Most business owners don’t realize this technical diagram is the difference between packaging success and disaster.

A dieline is a flattened template that contains precise cut lines, fold lines, perforation lines, and other manufacturing instructions that guide the entire production process. When you unfold any completed box and lay it flat, you’re looking at what a dieline represents – it’s the architectural drawing for your custom box.

The dieline acts as the communication bridge between all stakeholders in your packaging project. Without it, graphic designers wouldn’t know where to place logos and text, printers wouldn’t know where to print design elements, and manufacturers wouldn’t know where to fold and seal packaging.

Professional dielines include several critical elements that ensure manufacturing success:

- Cut lines: Solid lines (typically black) that indicate where material will be cut

- Fold lines: Dashed lines (often red) showing where material should be folded

- Bleed lines: Lines (commonly green) providing extra space beyond cuts for design elements

- Safety lines: Creating safe zones where critical content like logos should be placed

- Crease lines: Scored lines for thicker materials to ensure clean folds

- Perforation lines: Dotted lines for tear-away sections or easy-open features

| Component | Purpose | Visual Indicator |

|---|---|---|

| Cut Lines | Define cutting boundaries | Solid black lines |

| Fold Lines | Mark folding points | Dashed red lines |

| Bleed Lines | Extend artwork beyond edges | Green outline |

| Safety Lines | Protect critical content | Inner boundary lines |

At Acreet, we create comprehensive dielines for every custom packaging project, ensuring your boxes are manufactured exactly to your specifications. Our technical team understands that dielines serve as the foundation for all successful packaging production.

Why Are Dielines Critical for Manufacturing Success?

Many businesses underestimate the importance of accurate dielines until they face production disasters. The reality is that dielines determine whether your packaging project succeeds or fails.

Dielines are absolutely crucial for manufacturing success because they ensure precision and accuracy, facilitate clear communication between stakeholders, maintain quality control standards, and streamline the entire production process. They provide exact measurements for package sizing, scale, and dimensions while minimizing errors during production.

Manufacturing precision depends entirely on dieline accuracy. Professional dielines ensure that design aligns accurately with the packaging’s physical structure, preventing costly errors that can destroy entire production runs. Even minor miscalculations in measurements can lead to misaligned packaging or products that don’t fit properly.

Quality control becomes possible only with proper dielines. They help maintain consistent quality standards by providing standardized templates that have been tested and optimized for production. Without dielines, manufacturers cannot ensure that final packaging is consistently printed in the exact correct size and shape for your product.

Production efficiency increases dramatically with well-designed dielines. They provide a clear roadmap for production, reducing setup time and increasing production speeds. Professional manufacturers can optimize their equipment settings and reduce waste when working with accurate dielines.

• Dimensional accuracy: Prevents fitting problems and misalignment issues

• Communication clarity: Ensures all stakeholders understand production requirements

• Quality consistency: Maintains standards across large production runs

• Production speed: Reduces setup time and increases manufacturing efficiency

Cost control becomes manageable with proper dielines. They prevent expensive reprints and corrections that occur when designs don’t align with manufacturing requirements. The investment in professional dieline creation pays for itself by avoiding production disasters.

At Acreet, we’ve seen how proper dielines transform packaging projects from potential disasters into manufacturing successes. Our experienced team creates dielines that optimize every aspect of production while ensuring your vision becomes reality.

How Do Dielines Prevent Costly Production Errors?

Production errors in custom packaging can destroy profit margins and damage business relationships. Understanding how dielines prevent these disasters helps you appreciate their critical importance.

Dielines prevent costly production errors by ensuring dimensional accuracy, reducing material waste, maintaining design alignment, enabling thorough testing, and providing standardization. They act as quality control checkpoints that catch potential problems before production begins, preventing expensive mistakes that could cost thousands in wasted materials and delayed shipments.

Dimensional accuracy represents the most critical protection dielines provide. Even minor miscalculations can lead to misaligned packaging or products that don’t fit properly. Professional dielines specify exact measurements that account for material thickness and manufacturing tolerances.

Material waste reduction saves substantial money throughout production. Properly designed dielines optimize material usage and reduce waste during cutting and folding operations. They prevent situations where materials are cut incorrectly or dimensions are wrong, requiring costly reprints.

Design alignment protection ensures critical elements remain visible and properly positioned. Dielines prevent important design elements from being cut off or misaligned during production by including safety zones that keep logos, text, and artwork within non-cuttable areas.

Testing and validation become possible with accurate dielines. They enable thorough testing through prototypes before mass production begins, allowing brands to refine designs and catch potential issues early. This iterative process avoids costly corrections later in production.

| Error Type | Cost Impact | Prevention Method |

|---|---|---|

| Dimensional errors | Complete remake required | Precise dieline measurements |

| Material waste | 20-30% cost increase | Optimized cutting layouts |

| Design misalignment | Reprinting necessary | Proper safety zones |

| Assembly problems | Manual correction needed | Tested fold sequences |

Standardization through proven dieline templates helps avoid common pitfalls. Using pre-tested dielines from professional libraries reduces the back-and-forth typically required when designing from scratch, ensuring production-ready designs.

Quality assurance becomes systematic with professional dielines. They provide standardized checkpoints that manufacturers can use to verify accuracy throughout production, catching problems before they become expensive disasters.

Our team at Acreet understands that dieline accuracy directly impacts your bottom line. We create comprehensive dielines that prevent common production errors while optimizing manufacturing efficiency and cost control.

What Are the Key Components of a Professional Dieline?

Professional dielines contain specific technical elements that ensure manufacturing success. Understanding these components helps you evaluate dieline quality and work effectively with packaging manufacturers.

Professional dielines contain cut lines, fold lines, bleed lines, safety lines, crease lines, and perforation lines – each serving specific purposes in the manufacturing process. These components work together to provide complete instructions for cutting, scoring, folding, and assembling custom packaging with precision and consistency.

Cut lines define the exact boundaries where materials will be separated during production. These solid lines (typically black) indicate where the material will be cut to create the final package shape. Precision in cut lines is essential for proper fit and professional appearance.

Fold lines guide the folding process for accurate assembly. Usually shown as dashed lines (often red), these indicate where the material should be folded to form the package structure. Proper fold line placement ensures boxes assemble correctly and maintain structural integrity.

Bleed lines provide essential printing protection by creating extra space beyond cut lines where design elements should extend. These lines (commonly green) prevent white edges from appearing if the material shifts slightly during printing or cutting operations.

Safety lines create protected zones where critical design elements must be placed. These lines ensure that important content like text, logos, and artwork won’t be accidentally cut off during production, maintaining brand integrity and communication effectiveness.

Crease lines are added to thicker materials to ensure clean, precise folds. These scored lines are particularly important for corrugated and heavy cardboard applications where folding without creasing would create unsightly or weak fold lines.

Perforation lines indicate where tear-away sections should be created. These dotted lines are used for easy-open features, coupons, or other removable elements that enhance package functionality.

Additional professional elements include:

• Registration marks: Ensure accurate alignment during printing processes

• Color callouts: Specify exact colors using industry-standard systems

• Finishing notes: Detail special treatments like coating or embossing

• Assembly instructions: Guide production teams through complex folding sequences

At Acreet, our dieline specialists include all these professional elements in every custom packaging project. We provide comprehensive technical drawings that eliminate confusion and ensure precise manufacturing results.

How Do You Create an Effective Dieline for Custom Boxes?

Creating effective dielines requires technical expertise, specialized software, and deep understanding of manufacturing processes. The creation process involves several critical steps that determine production success.

Professional dieline creation involves determining exact requirements, choosing appropriate software, organizing design elements properly, specifying precise measurements, and conducting thorough testing. The process requires vector-based design tools and careful attention to manufacturing constraints and material properties.

Requirements determination forms the foundation of effective dieline creation. Start by establishing the exact size needed for your product, ensuring the packaging is the minimum size required for comfortable fit. Consider product weight, as heavier items require sturdier materials and reinforced dieline designs.

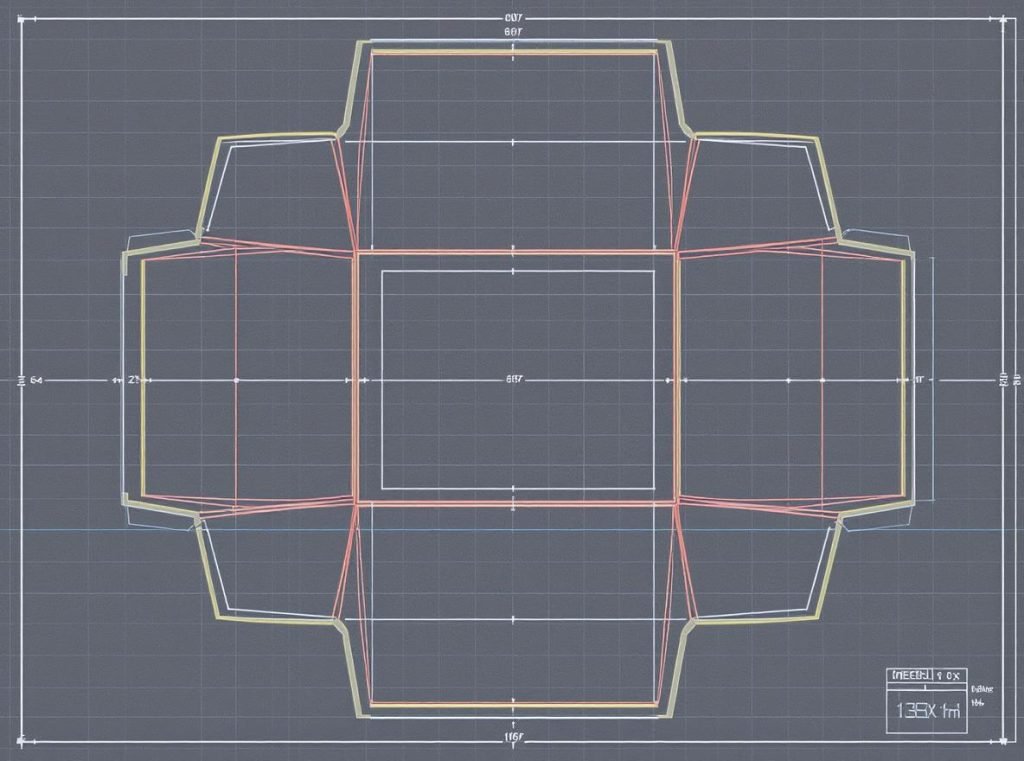

Software selection impacts dieline quality and compatibility. Professional dielines are typically created using Adobe Illustrator for precision and scalability, as it’s widely adopted throughout the packaging industry. For complex designs, specialized packaging CAD software like ArtiosCAD may be preferred for advanced features.

Layer organization ensures editability and clarity throughout the design process. Create separate layers for different components – keep the dieline template on one layer and artwork on another. This separation makes editing easier and ensures dielines can be toggled on and off as needed.

Precision specifications require careful attention to measurements and material properties. Use distinct colors and line types for different functions – solid lines for cuts and dashed lines for folds. Assign spot colors to dielines to make them stand out clearly during production.

| Creation Step | Key Considerations | Best Practices |

|---|---|---|

| Requirements | Product size, weight, protection needs | Minimum size for comfortable fit |

| Software | Industry compatibility, precision needs | Adobe Illustrator or ArtiosCAD |

| Organization | Layer separation, clear labeling | Dieline and artwork on separate layers |

| Specifications | Accurate measurements, material thickness | Account for scoring allowances |

Testing and validation ensure dielines work correctly before production investment. Always create physical prototypes to test the dieline before final manufacturing. This allows verification of dimensions, assembly processes, and overall functionality.

Material considerations affect dieline design significantly. Different materials require different approaches – corrugated materials need scoring allowances, while thinner materials may require different fold specifications. Account for material thickness and properties throughout the design process.

Professional manufacturers like Acreet handle the entire dieline creation process, from initial consultation through production-ready files. Our technical team ensures dielines meet all manufacturing requirements while optimizing for cost and efficiency.

What Software and Tools Are Used for Dieline Creation?

Professional dieline creation requires specialized software that ensures precision, compatibility, and industry-standard output. Understanding these tools helps you work effectively with packaging manufacturers and evaluate service providers.

Professional dieline creation uses Adobe Illustrator as the industry standard, ArtiosCAD for specialized packaging design, and various plugins and templates for enhanced functionality. These tools ensure precision, vector-based design capabilities, and compatibility with manufacturing equipment used throughout the packaging industry.

Adobe Illustrator dominates professional dieline creation due to its precision, vector-based design capabilities, and wide industry adoption. Most packaging companies can work with Illustrator files, making it the preferred choice for collaborative projects. Its measurement tools, path operations, and export options make it ideal for packaging design work.

ArtiosCAD represents the industry standard for structural packaging design. This specialized CAD software is built specifically for packaging professionals and offers advanced features like 3D visualization, automated drafting tools, and integration with manufacturing processes. It’s particularly valuable for complex custom packaging projects.

Specialized plugins enhance standard software capabilities. Tools like Dieline Genius provide Adobe Illustrator plugins with over 500 parametric packaging designs, offering libraries of proven professional templates that can be customized for specific needs.

Alternative software options serve specific requirements. Some professionals prefer AutoCAD for complex designs involving intricate cuts, rotations, and mirrors, as it offers more precision for complicated structures. Industry-specific tools like KASEMAKE provide comprehensive libraries of FEFCO and ECMA standards.

| Software Type | Primary Use | Key Advantages |

|---|---|---|

| Adobe Illustrator | General dieline creation | Industry standard, wide compatibility |

| ArtiosCAD | Specialized packaging design | 3D visualization, manufacturing integration |

| Dieline Genius | Template-based design | 500+ parametric designs, proven templates |

| AutoCAD | Complex structural designs | Precision for intricate cuts and rotations |

File format considerations ensure compatibility throughout the production process. Professional dielines are typically delivered in multiple formats including PDF for viewing, AI (Adobe Illustrator) for editing, EPS for compatibility, and specialized formats like DXF for CAD integration.

Output requirements vary by manufacturer and equipment type. Vector formats maintain precision at any scale, while specific color coding and layer organization ensure clarity during production. Professional dielines include proper spot colors and clear labeling for manufacturing equipment.

Quality control tools help verify dieline accuracy before production. These include measurement verification systems, layer organization checking, and compatibility testing with manufacturing equipment.

At Acreet, our design team uses professional software platforms to ensure compatibility with various client requirements and production equipment. We can work with files in any standard format and provide output in whatever format your project requires.

How Do Dielines Impact Production Costs and Timelines?

Understanding the relationship between dielines and production economics helps you make informed decisions about packaging investments. Proper dielines significantly affect both costs and delivery schedules.

Well-designed dielines reduce production costs by 25-40% through optimized material usage, reduced setup time, and prevention of costly errors. They can shorten production timelines by eliminating corrections and adjustments, while poor dielines extend delivery schedules and increase costs through reprints and remakes.

Cost reduction occurs through multiple mechanisms when dielines are properly designed. Material efficiency improvements reduce cardboard waste by optimizing cutting patterns for maximum usage. This efficiency becomes especially important for large orders where small percentage savings translate to significant cost reductions.

Setup time optimization affects production costs because manufacturers charge for machine preparation and calibration. Accurate dielines allow faster setup, reducing labor costs and enabling quicker delivery. Professional dielines with clear specifications eliminate guesswork and reduce setup time by 50-75%.

Error prevention represents the largest cost-saving opportunity. Manufacturing errors require remakes, which double material costs and extend delivery schedules. Quality dielines catch potential problems before production begins, preventing expensive corrections.

Timeline impacts affect business operations and customer satisfaction. Delayed packaging can disrupt product launches, create inventory shortages, and damage business relationships. Professional dielines help ensure on-time delivery by eliminating revision cycles.

| Cost Factor | Impact Range | Dieline Solution |

|---|---|---|

| Material efficiency | 15-25% savings | Optimized cutting layouts |

| Setup time | 50-75% reduction | Clear specifications |

| Error prevention | 25-40% savings | Accurate measurements |

| Timeline compression | 30-50% faster | Eliminate revision cycles |

Pricing considerations for professional dieline services typically range from $500-$2000 USD depending on complexity and requirements. However, this investment pays for itself by preventing costly production errors and optimizing manufacturing efficiency.

Production timeline factors vary by complexity, but proper dielines can reduce overall project duration significantly. Manufacturing processes that normally require extensive setup and correction time can proceed smoothly when dielines are accurate and complete.

Rush order capabilities depend heavily on dieline quality. When dielines are accurate and complete, manufacturers can prioritize orders without extensive preparation work. This flexibility is crucial for time-sensitive projects and competitive advantages.

Quality assurance processes become more efficient with proper dielines. Manufacturers can verify dimensions, check assembly accuracy, and ensure proper functionality more quickly when working with professional dielines.

At Acreet, we understand how dieline quality directly impacts our clients’ business success and bottom line. Our dieline services are designed to maximize cost savings while ensuring fast, accurate production that meets your timeline requirements.

What Common Mistakes Should You Avoid in Dieline Design?

Dieline mistakes can be expensive and time-consuming to correct, often requiring complete production reruns. Understanding common errors helps you avoid costly problems and ensures successful packaging production.

The most critical dieline mistakes include sizing and scaling errors, inadequate bleed areas, ignoring safety zones, poor file organization, material considerations oversight, insufficient testing, and proofreading oversights. These errors can result in unusable packaging, expensive reprints, and significant production delays.

Sizing and scaling errors represent the most costly dieline mistakes. Never flatten, scale, or resize dieline templates, as this is one of the most critical mistakes that can lead to dimensional inaccuracies and fitting problems. Even small scaling errors compound during manufacturing, especially when boxes need to fit specific products.

Inadequate bleed areas create visible white edges on finished packaging. Failing to account for proper bleed lines can result in incomplete printing coverage, requiring expensive reprints to achieve professional appearance. Always ensure artwork extends beyond cut lines by the specified bleed amount.

Safety zone violations put important design elements at risk of being cut off during production. Placing critical content like logos, text, and contact information too close to cut or fold lines can result in important brand elements being lost. Always maintain proper safety margins around critical content.

File organization problems cause confusion and delays during production. Not keeping dielines on separate layers or failing to use proper spot colors can create compatibility issues with manufacturing equipment. Always maintain clear layer organization and use appropriate color coding.

| Common Mistake | Consequences | Prevention Method |

|---|---|---|

| Sizing errors | Complete remake required | Never scale or resize templates |

| Inadequate bleed | Visible white edges | Proper bleed margins |

| Safety zone violations | Cut-off content | Maintain adequate margins |

| Poor file organization | Production delays | Clear layer separation |

Material considerations oversight leads to structural problems and assembly difficulties. Ignoring material thickness and properties when creating dielines can result in folding problems and weak structural points. Different materials require different scoring allowances and design approaches.

Insufficient testing exposes structural weaknesses and design flaws that become expensive to fix during production. Skipping the prototype phase can reveal problems that weren’t apparent in digital files. Always test dielines with physical prototypes before committing to large production runs.

Proofreading oversights result in costly reprints and potential compliance issues. Failing to thoroughly check text, dimensions, and technical specifications can lead to errors that require complete production reruns. Multiple review cycles help catch these problems early.

Quality control gaps allow errors to reach production stage. Without systematic checking processes, dieline problems can go undetected until manufacturing begins, when corrections become expensive and time-consuming.

Professional manufacturers like Acreet implement comprehensive quality control processes to catch dieline errors before they affect production. Our review procedures include dimension verification, file compatibility checking, and prototype testing to ensure success.

How Do You Work with Manufacturers to Perfect Your Dieline?

Successful dieline development requires effective collaboration between clients and manufacturers. Understanding this collaborative process helps ensure your custom packaging meets all requirements while optimizing costs and timelines.

Effective dieline collaboration involves early consultation with manufacturers, ensuring standard compliance, coordinating file formats, prototype collaboration, integrating feedback, establishing quality assurance procedures, and maintaining clear technical communication. This collaborative approach ensures dielines meet both functional requirements and production constraints.

Early consultation establishes project parameters and manufacturing requirements. Consult with your manufacturer before finalizing dieline specifications, as different manufacturers may have specific requirements or preferences for file formats and technical specifications. This early involvement prevents costly revisions later in the process.

Standard compliance ensures compatibility with manufacturing processes. Ensure dielines meet industry standards such as FEFCO (corrugated) or ECMA (folding carton) requirements. This compliance ensures compatibility with standard manufacturing equipment and processes throughout the industry.

File format coordination prevents technical delays and compatibility issues. Provide dielines in the manufacturer’s preferred formats – typically PDF for review, AI for editing, and sometimes DXF for CAD integration. Understanding format requirements early prevents delays during production preparation.

Prototype collaboration refines dielines based on manufacturing capabilities and recommendations. Work closely with manufacturers during the prototype phase to optimize designs for their specific equipment and processes. This collaboration often reveals opportunities for cost reduction and quality improvement.

Feedback integration improves dieline accuracy and manufacturing efficiency. Be prepared to iterate on dieline designs based on manufacturer feedback regarding production feasibility and optimization opportunities. Professional manufacturers provide valuable insights that improve final results.

Quality assurance procedures ensure dielines meet all manufacturing requirements before production investment. Establish clear quality control processes and sign-off procedures that protect both client and manufacturer interests by ensuring mutual agreement on specifications.

| Collaboration Stage | Key Activities | Expected Outcomes |

|---|---|---|

| Early consultation | Requirements review, constraint discussion | Clear project parameters |

| Standard compliance | FEFCO/ECMA verification, format checking | Manufacturing compatibility |

| Prototype development | Physical testing, refinement iterations | Optimized design validation |

| Quality assurance | Final review, formal approval | Production-ready dielines |

Technical communication maintains clarity throughout the development process. Maintain open communication about material specifications, production constraints, and any special requirements that might affect dieline design. Clear communication prevents misunderstandings that could delay production.

Project management ensures smooth workflow and timeline adherence. Establish clear milestones, review schedules, and approval processes that keep projects moving efficiently while maintaining quality standards.

Documentation and version control prevent confusion about current specifications. Maintain clear records of changes, approvals, and final specifications to ensure everyone works with current information throughout production.

At Acreet, we’ve developed streamlined collaboration processes that make dieline development efficient and effective. Our project managers guide clients through each step, providing technical expertise while respecting your vision and requirements. We maintain clear communication channels and provide regular updates throughout the development process.

Summary

Dielines are the technical foundation of successful custom box production, serving as precise blueprints that guide every aspect of manufacturing from initial cutting through final assembly. Professional dielines prevent costly errors, optimize material usage, and ensure consistent quality across production runs while facilitating clear communication between all stakeholders. Understanding dieline components, creation processes, and collaborative requirements helps you work effectively with manufacturers to achieve outstanding packaging results.

Ready to transform your packaging vision into reality with professional dieline services? Contact Acreet today for expert dieline development and custom box production. Our experienced technical team will work with you to create precise, cost-effective packaging solutions that protect your products and enhance your brand. Send us your packaging requirements, and let’s discuss how our professional dieline services can support your business success with optimized manufacturing efficiency and quality assurance.