Running an e-commerce business means choosing packaging that protects your products while creating memorable brand experiences. With over 70% of D2C brands using corrugated boxes with custom branding, selecting the right mailer style has become crucial for business success.

A Roll End Tuck Front (RETF) mailer box is a specialized packaging solution featuring a self-locking closure system where the front panel tucks into the main body without requiring tape or glue. Also known as Roll End Front Tuck (REFT) boxes, these mailers include “Cherry Locks” – self-locking tabs that secure the front closure and dust flaps for additional protection, making them the #1 choice for subscription box packaging and e-commerce shipping.

Let’s explore why RETF boxes are revolutionizing packaging across industries and how they can transform your shipping strategy.

Table of Contents

ToggleHow Does a Roll End Tuck Front Box Work?

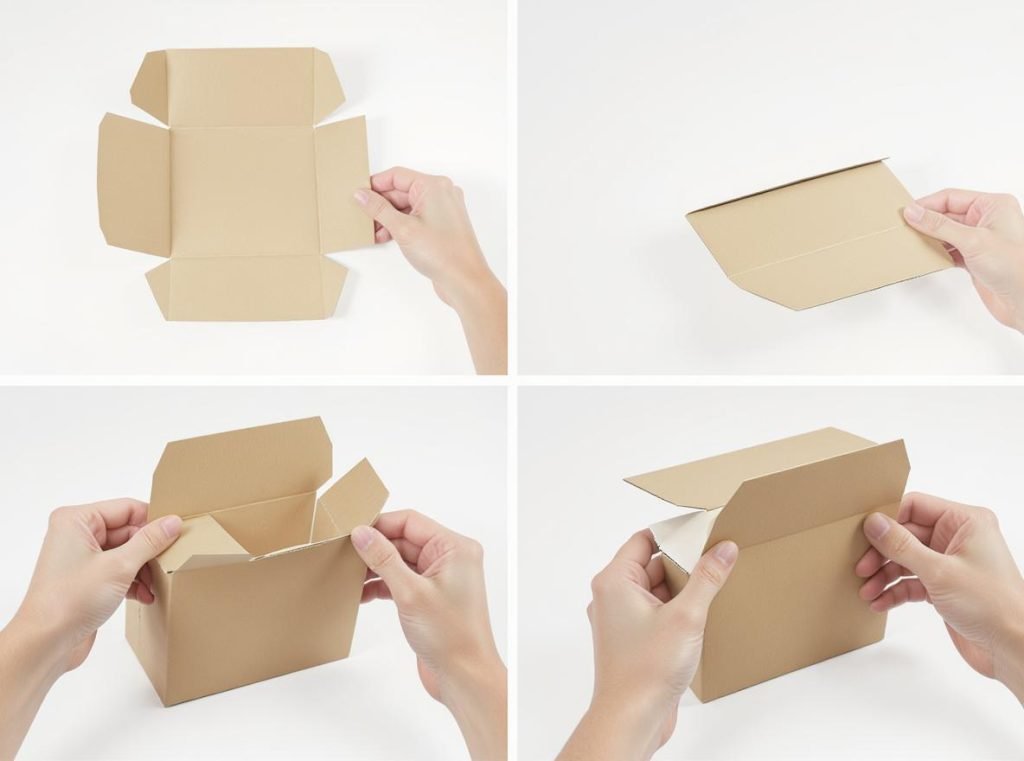

Understanding the assembly mechanism helps you appreciate why RETF boxes have become so popular among packaging professionals.

RETF boxes operate through a simple three-step assembly process that takes approximately 1 minute for most users, with experienced assemblers completing it in just 30 seconds. The design eliminates the need for additional adhesives or fasteners while providing secure product protection.

The assembly process involves three key stages. First, you fold the front and back panels upward, then fold the flaps on either end inward toward the center. Next, fold the side panels up and over the front and back flaps, tucking the tabs into the bottom slots to lock them in place. Finally, fold the lid down over the box, with two “ears” on either side of the front flap folding inward before the front flap tucks downward into the sides.

The Cherry Locks system creates the secure closure that prevents accidental opening during transit. These self-locking tabs maintain the box’s integrity throughout shipping while ensuring a smooth unboxing experience for customers.

The rounded flaps are engineered to smoothly tuck into the front of the main body, creating what industry professionals call a “treasure chest-like” opening experience. This design feature significantly enhances customer satisfaction and brand perception.

What Are the Key Benefits of RETF Mailer Boxes?

RETF mailer boxes offer compelling advantages that explain their widespread adoption across industries.

RETF boxes provide superior security, cost efficiency, and branding opportunities compared to traditional shipping boxes, with the added benefit of requiring no tape or glue for assembly. These advantages make them particularly attractive for businesses focused on premium customer experiences.

The security benefits are substantial. The tamper-resistant design prevents accidental opening during transit, while the enhanced structural integrity from the tuck-front closure system provides excellent product protection. Dust flaps, when included, offer additional protection from dirt and debris.

Cost efficiency represents another major advantage. With no tape or glue required for assembly, businesses reduce material costs significantly. The lightweight construction minimizes shipping expenses, while flat shipping saves storage space and transportation costs.

| Benefit Category | Specific Advantages | Measurable Impact |

|---|---|---|

| Security | Tamper-resistant design, dust flaps | Reduced damage claims, better product protection |

| Cost Efficiency | No tape/glue needed, lightweight construction | Lower material costs, reduced shipping expenses |

| Branding | Premium unboxing experience, large surface area | Enhanced customer satisfaction, improved brand perception |

| Operations | 30-second assembly time, consistent quality | Reduced labor costs, reliable performance |

Branding opportunities with RETF boxes are extensive. The large surface area allows for comprehensive logos, colors, and custom designs, while the premium unboxing experience significantly enhances customer satisfaction and brand loyalty.

Operational benefits include quick assembly that reduces labor costs, consistent quality that ensures reliable performance, and a reusable design that adds value for customers while supporting sustainability initiatives.

Which Industries Use RETF Mailer Boxes Most?

RETF mailer boxes have achieved remarkable penetration across multiple industries, driven by their versatility and premium presentation capabilities.

E-commerce represents the largest market segment with over 62% of volume demand, while subscription boxes account for 21% of volume demand, making RETF boxes essential for businesses focused on customer experience. The global mailer box market is expected to reach $8.4 billion by 2035 at a CAGR of 6.7%.

E-commerce dominance reflects the growing importance of branded packaging in online retail. Electronics shipping particularly benefits from RETF security features, while apparel and fashion items leverage the professional presentation capabilities. Small to medium-sized products that require branded packaging represent the sweet spot for RETF applications.

The subscription box industry has embraced RETF boxes as their preferred choice due to several factors:

- Consistent unboxing experience that builds customer loyalty

- Structural integrity for repeated handling during shipping

- Extensive branding opportunities for monthly engagement

- Professional appearance that reflects product quality

Specialized industries finding success with RETF boxes include beauty and cosmetics for premium product presentation, food packaging including bakery and pastry applications, pharmaceuticals requiring secure tamper-evident packaging, and cannabis products needing compliant secure packaging solutions.

The versatility of RETF boxes extends to electronics and tech accessories, clothing and fashion items, books and media products, artisanal and craft products, and promotional marketing materials. This broad applicability explains why RETF boxes have become a go-to solution for businesses across diverse sectors.

How Do RETF Boxes Compare to Other Mailer Styles?

Understanding the competitive landscape helps businesses make informed packaging decisions based on their specific requirements.

RETF boxes offer superior security and premium unboxing experiences compared to Roll End Tuck Top (RETT) boxes, while providing better branding opportunities than regular shipping boxes, though at a higher initial cost. The total cost of ownership often favors RETF boxes due to operational savings.

The comparison with RETT boxes reveals key differences. RETF boxes use front tuck with cherry locks, providing higher security through self-locking tabs. RETT boxes use top tuck into the box interior, offering lower security and typically requiring tape for secure shipping. Material usage is higher for RETF boxes due to additional flaps, while RETT boxes use less material and are more cost-effective initially.

Assembly time differences are minimal but important. RETF boxes require slightly longer assembly but create a premium treasure chest-like unboxing experience. RETT boxes offer faster assembly with a simple, functional opening experience.

When compared to regular shipping boxes, RETF boxes excel in several areas:

- Brand presentation: Premium and customizable versus basic and functional

- Assembly requirements: No tape needed versus tape required for all closures

- Initial cost: Higher material cost versus lower base cost

- Durability: High structural integrity versus moderate protection

- Customer experience: Enhanced unboxing versus standard delivery

The investment in RETF boxes typically pays dividends through improved customer satisfaction, reduced damage claims, and enhanced brand perception that supports premium pricing strategies.

What Should You Consider When Choosing RETF Boxes?

Selecting the optimal RETF box specifications requires careful evaluation of technical constraints and business requirements.

Size limitations, material selection, and customization options are the three most critical factors when specifying RETF boxes, with depth not exceeding length and minimum dimensions typically starting at 3″ (L) x 3″ (W) x 1″ (D). Understanding these parameters ensures optimal performance and cost-effectiveness.

Size and dimensional constraints play a crucial role in RETF box functionality. The depth must not exceed length for structural integrity, while minimum dimensions typically start at 3″ (L) x 3″ (W) x 1″ (D). Weight capacity recommendations suggest a maximum of 2 lbs per 100 square inches for standard paperboard applications.

Material selection impacts both performance and cost. Corrugated cardboard works best for shipping applications requiring durability, while 18-24pt paperboard suits lighter products and retail packaging. For heavier items needing maximum protection, 32 B-flute corrugated provides optimal strength-to-weight ratio.

Customization options significantly influence both cost and brand impact:

- Full-color CMYK printing available on one or both sides

- Finishing options including matte, gloss, or special coatings

- Dust flaps for additional side protection of sensitive products

- Window cutouts for product visibility without compromising security

Volume and cost considerations affect project feasibility. Minimum order quantities typically range from 500-2,000 units for custom orders, with bulk pricing providing significant cost reductions for higher volumes. Setup costs for initial tooling and printing plates represent one-time expenses that spread across larger quantities.

Lead times vary based on customization complexity, with standard sizes and simple printing shipping within days, while fully custom designs with special finishes may require several weeks for production and delivery.

How Can You Maximize RETF Box Effectiveness?

Optimizing RETF box performance requires strategic planning across design, materials, and operational considerations.

Design optimization, structural enhancements, and sustainability features work together to maximize RETF box effectiveness while supporting operational efficiency and environmental goals. Small details can significantly impact both functionality and customer perception.

Design optimization starts with artwork flow that complements the box structure and flows naturally across panels. Color psychology should align with brand identity and evoke desired emotions, while typography selection must match brand personality and ensure readability across all box surfaces.

Structural enhancements can dramatically improve functionality. Custom inserts organize products and prevent movement during transit, while dust flap inclusion provides additional structural support and dust protection. Strategic window cutouts showcase products without compromising security when properly implemented.

Sustainability features have become increasingly important, with 48% of orders for mono-material kraft boxes due to recyclability concerns. Minimalist design reduces ink usage and supports sustainability goals, while designing for customer reuse adds value and reduces waste.

Operational efficiency improvements include:

- Standardized sizes to reduce inventory complexity

- Assembly training to reduce time from 1 minute to 30 seconds

- Quality control measures ensuring consistent performance

- Supplier relationship management for reliable delivery

Advanced strategies include variable data printing for personalized messaging, seasonal design variations to maintain customer interest, and integration with automated packaging systems for high-volume operations.

What Are the Cost Considerations for RETF Boxes?

Understanding the comprehensive cost structure enables informed budgeting and ROI calculations for RETF box implementation.

Initial investment includes setup costs ranging from $3,000-$5,000 for custom designs, while per-unit costs vary based on volume, with significant savings available for orders exceeding 10,000 units. Total cost of ownership often favors RETF boxes due to operational savings.

Initial investment factors include setup costs for custom designs and tooling, minimum order quantities typically ranging from 500-2,000 units, and artwork design fees that may add $500-$2,000 for professional services.

Per-unit cost components vary significantly based on specifications. Base material costs depend on size, material quality, and corrugation type. Printing expenses add $0.10-$0.50 per unit for full-color printing, depending on complexity. Finishing costs for special coatings or treatments can add $0.05-$0.25 per unit.

Volume-based pricing creates opportunities for significant savings:

- Small orders (500-1,000 units): Higher per-unit costs but lower total investment

- Medium orders (2,000-5,000 units): Balanced cost-effectiveness for growing businesses

- Large orders (10,000+ units): Significant per-unit savings suitable for established operations

Shipping and logistics considerations include overseas manufacturing options that can reduce unit costs by 30-50% but require larger minimum orders. Sea freight costs approximately $0.30-$0.50 per unit for international shipping, while domestic shipping offers faster delivery but higher costs for smaller quantities.

Hidden cost benefits often make RETF boxes more economical than initial comparisons suggest, including eliminated tape and adhesive costs, reduced assembly labor, lower damage rates, and improved customer satisfaction leading to repeat business.

How Do You Get Started with RETF Mailer Boxes?

Successfully implementing RETF boxes requires systematic planning and strategic supplier partnerships.

Start with thorough needs assessment, then work with experienced suppliers to develop prototypes before scaling to full production, allowing 5-7 days for production plus shipping time. This approach minimizes risk while ensuring optimal results.

The assessment and planning phase involves evaluating your specific needs including product dimensions, weight, and protection requirements. Budget planning should allocate funds for initial setup, minimum orders, and ongoing supplies. Timeline consideration must account for production lead times and shipping schedules.

Supplier selection requires careful evaluation of capabilities and credentials. Research manufacturers using platforms like Alibaba for international suppliers or ThomasNet for domestic options. Evaluate credentials including trade assurance, certifications, and positive customer reviews. Always request physical samples before placing large orders.

Design and prototyping steps include creating initial concepts using supplier-provided dielines, testing prototypes through small quantity orders, and refining designs based on testing results and customer feedback.

Implementation strategy should start small with minimum orders to test market response, build long-term relationships with reliable suppliers, and scale gradually as demand grows and cash flow improves.

Best practices for getting started include:

- Documenting current packaging challenges and costs

- Setting clear performance metrics for improvement

- Establishing quality control processes

- Planning for seasonal demand variations

- Building buffer inventory for consistent supply

At Acreet, we understand the complexities of transitioning to RETF mailer boxes. Our experienced team provides comprehensive support from initial consultation through full-scale production, ensuring your packaging solution meets both functional requirements and brand objectives.

Our global manufacturing capabilities enable competitive pricing while maintaining quality standards, and our design team can help optimize your packaging for maximum impact and efficiency.

What Are the Latest Trends in RETF Box Design?

The packaging industry continues evolving with new technologies and consumer preferences driving innovation in RETF box design.

Sustainability features, smart packaging integration, and enhanced customization options represent the leading trends shaping RETF box development in 2025. These trends reflect growing environmental consciousness and technological capabilities.

Sustainability remains the dominant trend, with mono-material kraft boxes representing 48% of orders due to recyclability advantages. Minimalist design approaches reduce ink usage while maintaining brand impact. Biodegradable coatings and water-based inks support environmental goals without compromising functionality.

Smart packaging integration includes QR codes for enhanced customer engagement, NFC tags for product authentication, and augmented reality features that create interactive unboxing experiences. These technologies bridge physical and digital brand touchpoints.

Enhanced customization options now include variable data printing for personalized messaging, seasonal design variations to maintain customer interest, and modular design systems that allow mix-and-match components for different product lines.

The future of RETF boxes looks promising, with industry experts predicting continued growth in e-commerce applications and expanding adoption in traditional retail channels. Advances in digital printing technology are making smaller custom runs more cost-effective, while automation improvements are reducing assembly time and costs.

Summary

RETF mailer boxes represent the perfect balance of security, branding opportunity, and cost-effectiveness for businesses shipping products globally. With their self-locking Cherry Locks system, dust flap protection, and premium unboxing experience, they’ve become the #1 choice for subscription boxes and a preferred solution for e-commerce applications. Understanding the benefits, applications, and implementation strategies positions your business to leverage these innovative packaging solutions effectively.

Ready to transform your packaging strategy with custom RETF mailer boxes? Contact Acreet today to discuss your specific requirements and discover how our expertise in custom packaging solutions can enhance your brand while optimizing costs and customer satisfaction.