Are you struggling to find packaging that delivers both stunning visual appeal and the structural strength needed for product protection? Many businesses face the challenge of choosing between premium graphics and robust packaging materials, often compromising on one aspect.

Litho-lamination on corrugated board is a specialized printing and packaging process that combines high-quality lithographic printing with the structural strength of corrugated cardboard. This technique involves printing decorative graphics onto paper liner board using offset lithography, then laminating (bonding) that printed liner board onto a corrugated substrate. The result is packaging that offers the strength and durability of corrugated board with the visual quality of premium lithographic printing.

Let’s explore everything you need to know about this innovative packaging solution and how it can transform your brand’s packaging strategy.

Table of Contents

ToggleHow Does the Litho-Lamination Process Work?

Understanding the technical process behind litho-lamination helps you appreciate why it delivers superior results compared to traditional corrugated printing methods.

The litho-lamination process consists of three main stages: offset lithographic printing, lamination bonding, and finishing operations. This multi-stage approach ensures both exceptional print quality and structural integrity in the final product.

The process begins with offset lithographic printing, which operates on the principle that oil and water don’t mix. Specialized printing plates are created for each color, typically using the CMYK process (cyan, magenta, yellow, and black). The printing involves applying ink to the greasy image areas of the plate while water adheres to non-greasy areas, then transferring the ink from the printing plate to a rubber blanket, and finally to the paper substrate.

Stage 1: Lithographic Printing

The decorative graphics are first printed onto smooth paper liner using offset printing technology. Because litho-lamination prints to the liner board before it’s attached to the corrugated fluting, it has the advantage of printing on a perfectly smooth surface, allowing for incredibly detailed, high-resolution graphics that would be impossible when printing directly onto corrugated material.

Stage 2: Lamination Process

The printed sheets are then adhered to corrugated board through three specialized sections:

- Wet End: Creates single-face corrugated from reels of liner and fluting papers using single facer groups

- Laminating Section: A gluing unit applies adhesive to the flute tips of the corrugated carrier, and the printed paper is aligned and adhered to create the bond

- Delivery Section: The laminated board passes through two drying stages to ensure proper bonding before final delivery

Stage 3: Finishing Operations

After lamination, the sheets undergo die-cutting and finishing processes where they’re shaped according to the desired packaging design. Additional finishing options like embossing, foil stamping, UV coating, and various surface treatments can be applied to enhance the final appearance.

What Are the Main Advantages of Litho-Lamination?

Businesses choose litho-lamination for packaging because it offers unique benefits that traditional corrugated printing simply cannot match in terms of quality and performance.

Litho-lamination delivers exceptional print quality with photo-like resolution, superior durability, and cost-effectiveness for high-volume production runs. Since the printing occurs on smooth paper before lamination to corrugated board, it avoids the texture issues that can compromise direct printing on corrugated surfaces.

The superior print quality stems from the smooth printing surface, allowing for fine detail reproduction with sharp text and intricate graphics. You can achieve dot patterns as small as 1% without losing clarity, making it perfect for complex logos, product photography, and detailed artwork that demands precision.

Enhanced Color Vibrancy and Consistency

The smooth liner surface accepts ink more evenly, resulting in richer, more vibrant colors. This is particularly important for brands that rely on specific color matching for brand recognition. The process supports full-color printing with vibrant graphics and maintains color consistency across large production runs.

Superior Durability and Protection

The combination of lithographic printing and corrugated backing provides superior strength and protection for products during shipping and handling. The corrugated layer offers structural integrity while the printed top sheet maintains its visual appeal throughout the supply chain. The laminated surface also resists scuffing and moisture better than traditional corrugated printing.

| Advantage | Benefit | Applications |

|---|---|---|

| Print Quality | Photo-like resolution, vibrant colors | Premium brands, retail displays |

| Durability | Scratch and moisture resistant | Shipping, high-value products |

| Cost Efficiency | Lower per-unit cost for large runs | High-volume orders (1,000+ units) |

| Customization | Multiple finishing options available | Brand differentiation, luxury packaging |

| Environmental | 100% recyclable with proper materials | Sustainable packaging goals |

When Should You Choose Litho-Lamination Over Other Printing Methods?

The decision between litho-lamination and other printing methods depends on your specific volume requirements, quality expectations, and budget considerations.

Choose litho-lamination when producing 1,000+ units or more, as the break-even point typically occurs around 1,000 pieces. After this threshold, litho-lamination becomes more cost-effective than digital printing alternatives while delivering superior quality results.

Litho-lamination excels when superior print quality is essential for your brand presentation. If your design requires large blocks of solid color, fine detail reproduction, or photographic-quality images, litho-lamination delivers smoother, more professional results than digital alternatives.

Volume and Cost Considerations

The high setup costs associated with plate creation and machine setup make litho-lamination most economical for larger production runs. Setup costs are amortized over large quantities, reducing per-unit costs significantly. Most suppliers require minimum orders of 2,500-3,000 sheets to justify setup costs.

Quality Requirements

- Multiple colors (4+ color process)

- Photographic images requiring high resolution

- Fine text or intricate details

- Specific color matching requirements

- Premium brand presentation needs

Retail and Brand-Critical Applications

Opt for litho-lamination for retail-ready packaging and point-of-sale displays where visual impact drives purchasing decisions. With 70% of purchasing decisions made at the point of sale, high-quality graphics can significantly influence consumer behavior and justify premium pricing.

Structural Strength Requirements

Select litho-lamination when packaging must withstand shipping stresses while maintaining visual appeal. The corrugated backing provides protection for fragile or valuable products while the printed surface maintains brand presentation throughout the distribution chain.

What Are the Limitations of Litho-Lamination?

While litho-lamination offers exceptional benefits, understanding its limitations helps you make informed packaging decisions for your specific requirements.

The primary limitations include high setup costs, extended lead times, and minimum order requirements that make it unsuitable for small batches or frequently changing designs. These factors require careful planning and volume commitment to achieve cost-effectiveness.

Initial setup costs are significant due to plate creation and machine configuration requirements. Printing plates can cost substantial amounts for high-speed equipment, and each color requires separate plates. This makes design changes expensive once production begins, as modifications require new plate creation.

Extended Lead Times and Planning Requirements

The process typically requires generous lead times of several weeks to months, especially during peak seasons. Production takes significantly longer than digital alternatives due to complex plate-making and setup procedures. This requires better inventory planning and reduces flexibility for rush orders.

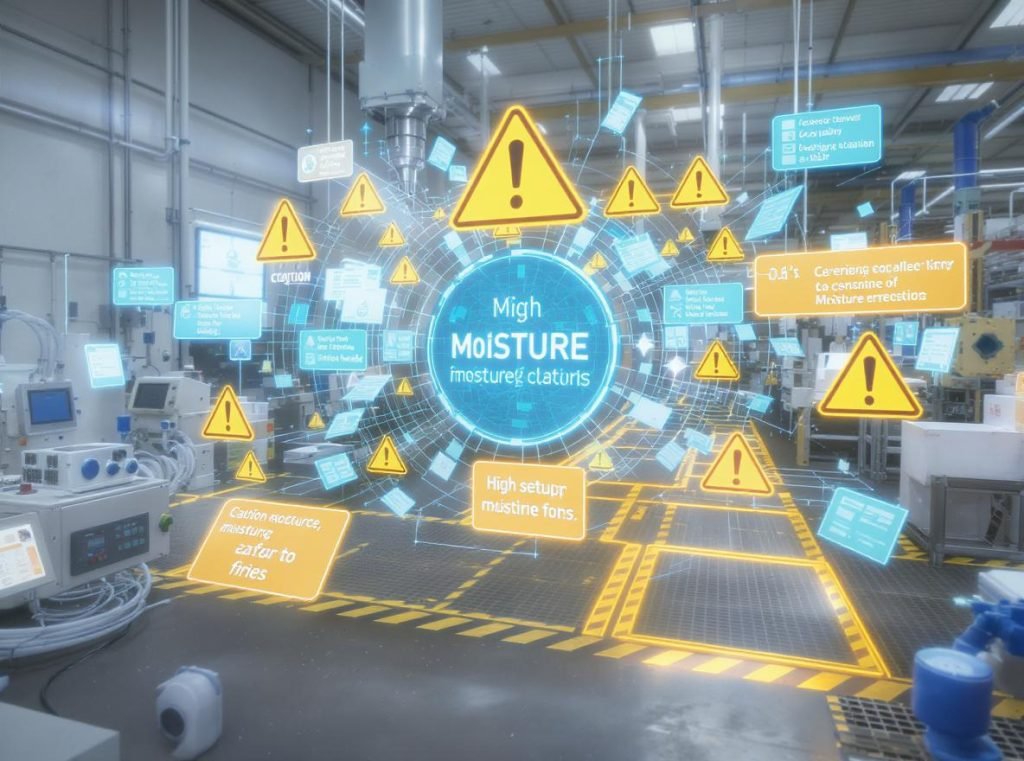

Moisture Sensitivity Issues

Litho-lamination is highly sensitive to moisture content in both the paper and corrugated substrates. Mismatched moisture levels can cause warping, cracking creases, bubbling, and tunneling effects. This requires careful environmental controls and moisture monitoring throughout production.

Design and Technical Constraints

- Panels that join on creases can cause production problems

- Large blocks of solid dark colors over score lines may crack

- Limited customization once plates are created

- Requires specialized expertise and equipment

- Higher waste rates during setup and changeovers

Volume Requirements

Most suppliers require minimum orders that may exceed smaller businesses’ needs. The economics only work favorably for established products with predictable demand patterns, making it unsuitable for test markets or limited editions.

How Does Litho-Lamination Compare to Digital Printing?

Understanding the differences between litho-lamination and digital printing helps you choose the right method based on your specific project requirements and business objectives.

Litho-lamination generally produces higher quality results with smoother color gradients and better handling of solid color blocks, while digital printing offers faster turnaround times and lower minimum quantities. Each method has distinct advantages depending on your volume, timeline, and quality requirements.

Digital printing excels for smaller quantities (under 1,000 units) and offers faster turnaround times, typically 2-3 days versus 7+ days for litho-lamination. Digital requires no setup time and allows for customization and variable data printing, enabling different designs within the same production run.

Quality and Finish Differences

Litho-lamination delivers superior print quality with smoother color gradients and better solid color reproduction. Digital printing has improved significantly but still shows some limitations with large solid areas and may exhibit a different finish texture. The lithographic process provides more consistent color reproduction across large runs.

| Cost Analysis by Volume | Factor | Digital Printing | Litho-Lamination |

|---|---|---|---|

| Setup Cost | None | High | |

| Per-Unit Cost | Higher | Lower (at volume) | |

| Break-Even Point | Under 1,000 units | Over 1,000 units | |

| Turnaround Time | 2-3 days | 7+ days | |

| Quality Level | Good | Excellent | |

| Customization | High flexibility | Limited once set |

Material Compatibility

Digital printing can handle paper weights from 70-350gsm, while litho-lamination offers more flexibility with various substrate weights from 60-500gsm. Litho-lamination also works better with specialty materials and coatings, providing more options for premium finishes.

When to Choose Each Method

Choose digital for small runs, test markets, personalized packaging, or when quick turnaround is essential. Select litho-lamination for large volumes, premium quality requirements, retail displays, or when consistent branding across thousands of units is crucial.

What Industries Benefit Most from Litho-Laminated Packaging?

Certain industries particularly benefit from the unique combination of visual appeal and structural strength that litho-lamination provides for their packaging applications.

The food and beverage industry represents over 30% of the litho-laminated packaging market, followed by consumer electronics, cosmetics, and pharmaceuticals. These industries value the combination of attractive shelf presentation and protection during distribution.

Food and beverage companies use litho-lamination for products requiring both attractive shelf presentation and protection during distribution. Applications include beverage cartons, frozen food packaging, premium food displays, and specialty product launches where visual impact drives purchasing decisions.

Consumer Electronics and Technology

Electronics manufacturers rely on litho-lamination for product packaging that must protect valuable items while showcasing brand quality. The combination of structural strength and high-quality graphics makes it ideal for smartphone boxes, appliance packaging, and electronics accessories where unboxing experience matters.

Cosmetics and Personal Care

The cosmetics industry values litho-lamination for premium brand presentation and luxury appearance. The process delivers the upscale look required for high-end cosmetic packaging while providing adequate protection for fragile products during shipping and retail display.

Pharmaceutical and Healthcare

Pharmaceutical companies use litho-lamination for regulatory compliance and brand protection. The process allows for detailed product information printing while maintaining package integrity throughout the supply chain, ensuring critical information remains legible and secure.

E-commerce and Retail Growth

The growth of online shopping has increased demand for packaging that creates memorable unboxing experiences. Litho-lamination provides the visual impact needed for e-commerce packaging while ensuring products arrive undamaged, supporting both brand building and customer satisfaction.

Automotive and Industrial Applications

Auto parts manufacturers use litho-lamination for heavy-duty packaging applications. The process provides the strength needed for automotive components while allowing for detailed part identification and branding requirements.

How to Choose the Right Litho-Lamination Partner?

Selecting the appropriate litho-lamination provider requires careful evaluation of technical capabilities, quality standards, and service levels to ensure successful project outcomes.

Look for partners with state-of-the-art equipment from reputable manufacturers like BOBST or Lamina System, along with quality certifications and proven experience in your industry. The right partner combines technical expertise with reliable service and competitive pricing.

Technical capabilities should include modern equipment that can handle your specific requirements including sheet sizes, flute types (C, B, D, E, F, N), and substrate weights. Verify their machinery specifications and production capacity to ensure they can meet your volume requirements efficiently.

Quality Certifications and Standards

Choose suppliers with G7 certification to ensure color consistency and print quality. Look for environmental certifications like FSC, SFI, or PEFC if sustainability is important to your brand. ISO compliance indicates systematic quality management processes that ensure consistent results.

Production Capacity and Service

Ensure your partner can handle your volume requirements without compromising quality or deadlines. Verify their minimum order quantities align with your needs and confirm they have sufficient capacity during peak seasons. Look for dedicated customer support teams throughout the project lifecycle.

Technical Support and Expertise

Select partners who understand your converting process and can optimize for your specific equipment and applications. They should offer adhesive expertise, moisture control systems, and troubleshooting support. Effective communication from quoting through delivery ensures smooth project execution.

Environmental Controls and Quality Systems

Choose partners with moisture-controlled pressrooms and proper testing equipment. They should monitor moisture levels from mill to delivery and provide documentation of environmental conditions to prevent quality issues.

| Evaluation Factor | What to Look For | Why It Matters |

|---|---|---|

| Equipment Quality | Modern machinery, reputable brands | Consistent quality, efficient production |

| Certifications | G7, FSC, ISO standards | Quality assurance, environmental compliance |

| Technical Support | Process expertise, troubleshooting | Problem resolution, optimization |

| Capacity | Volume handling, peak season capability | Meeting deadlines, scalability |

| Geographic Location | Shipping costs, service access | Total cost, communication ease |

Geographic and Logistical Considerations

Consider location advantages for shipping costs and lead times. Local partners may offer better service and reduced transportation costs while maintaining quality standards. Evaluate the financial health and industry reputation of potential partners to ensure long-term reliability.

Summary

Litho-lamination on corrugated board combines premium print quality with structural strength, making it ideal for high-volume packaging that needs exceptional visual appeal and durability. While it requires higher minimum quantities and longer lead times than digital alternatives, the superior quality and cost efficiency for large runs make it invaluable for established brands and retail-ready packaging applications.

Ready to elevate your packaging with professional litho-lamination solutions? Contact Acreet today for expert consultation on your custom packaging needs. Our experienced team specializes in litho-laminated packaging for global wholesalers, distributors, and manufacturers. We’ll help you determine if litho-lamination is the right solution for your products and provide detailed samples and competitive quotes tailored to your specific requirements. Let’s create packaging that truly represents your brand’s quality and drives results in your target markets.