Managing packaging prototype revisions feels like juggling flaming torches while blindfolded. With over 40% of packaging startups failing within five years due to revision management issues, you need a system that actually works.

The best way to manage revisions and approvals for packaging prototypes is implementing a structured 11-step framework with centralized feedback systems, clearly defined stakeholder roles, and specialized collaboration tools. This approach reduces revision cycles by 40% while maintaining quality standards.

Let me show you how successful companies transform chaotic revision processes into streamlined operations that deliver results.

Table of Contents

ToggleWhy Do Most Packaging Prototype Revisions Fail?

Understanding why revision processes collapse helps you avoid the same costly mistakes that derail countless projects.

Most packaging prototype revisions fail due to scattered feedback systems, unclear approval hierarchies, and manual proofing errors. These issues create confusion, duplicate work, and extended timelines that frustrate stakeholders and delay product launches.

The primary culprit is the lack of a single source of truth. When multiple versions exist across email threads, shared drives, and personal desktops, stakeholders unknowingly review outdated files. This creates unnecessary rework and conflicting feedback that sends projects into endless revision loops.

Scattered feedback collection compounds the problem significantly. Brand managers provide input through PDFs, legal teams send annotated screenshots, and compliance teams share thoughts via email. Design teams waste valuable time chasing down disparate inputs instead of focusing on implementation.

Manual proofing processes create another major failure point. Examining flattened PDFs for color accuracy, font compliance, or regulatory requirements is both tedious and error-prone. Critical issues slip through that surface during final quality checks, forcing expensive corrections.

Poor stakeholder communication also derails projects. When design and artwork errors like spelling mistakes or visual problems aren’t caught early, they multiply throughout the process. Similarly, inadequate product protection assessment leads to packaging that fails during transportation or storage.

How Should You Structure Your Packaging Prototype Approval Process?

A well-structured approval process creates predictable workflows that balance speed, quality, and compliance requirements.

Structure your packaging prototype approval process using an 11-step framework: design brief development, research, concept development, refinement, design review, iteration, prototype creation, testing, approval gatekeeping, production preparation, and user validation. This systematic approach ensures comprehensive coverage while maintaining momentum.

The framework begins with solid foundation work through design brief development and research phases. These early stages establish clear goals, strategy, and market requirements that guide all subsequent decisions.

Concept development and refinement phases focus on creative exploration and polishing ideas. The design review stage introduces structured feedback collection, followed by iteration cycles that implement improvements based on stakeholder input.

Your structured process should include these essential components:

- Clear role definition: Establish who seeks approvals and who has authority to grant them

- Information collection: Systematically gather all necessary files and documentation

- Approval criteria: Define specific, measurable requirements for each milestone

- Stakeholder collaboration: Engage relevant parties through structured feedback loops

- Documentation tracking: Maintain detailed records of approvals, changes, and decisions

The final phases cover prototype creation, testing and validation, approval gatekeeping, production preparation, and user validation. Each stage builds upon previous work while maintaining quality standards.

Consider whether to implement parallel or sequential review processes. Sequential reviews ensure thorough evaluation and reduce conflicts but can create bottlenecks. Parallel reviews accelerate timelines but may generate conflicting feedback that requires additional resolution time.

What Are the Key Roles in Packaging Prototype Revision Management?

Defining clear roles eliminates confusion and ensures accountability throughout the revision process.

Key roles include Regulatory Affairs for compliance oversight, Quality Assurance for process validation, Marketing for brand consistency, Manufacturing for production feasibility, Legal for intellectual property protection, and Supply Chain for material sourcing. Each role brings unique expertise and specific responsibilities.

Regulatory Affairs ensures compliance with legal and market-specific requirements. They review labeling for accuracy and validate that all regulatory standards are met before granting production approval. This role is critical for avoiding costly compliance issues later.

Quality Assurance oversees the entire process, verifying that internal procedures are followed correctly. They provide final approval after confirming all quality standards are maintained throughout the revision cycle.

Marketing teams ensure brand consistency and validate messaging accuracy. They confirm that packaging aligns with overall brand strategy and consumer expectations while supporting marketing objectives.

| Role | Primary Responsibility | Key Validation Areas |

|---|---|---|

| Regulatory Affairs | Compliance oversight | Legal requirements, labeling accuracy |

| Quality Assurance | Process validation | Quality standards, procedure adherence |

| Marketing | Brand consistency | Message accuracy, consumer alignment |

| Manufacturing | Production feasibility | Technical specs, equipment compatibility |

| Legal | IP protection | Trademark compliance, legal requirements |

| Supply Chain | Material sourcing | Availability, cost, logistics |

Manufacturing reviews technical specifications and validates production feasibility. They ensure designs can be efficiently produced using existing equipment and processes while meeting quality standards.

Legal teams examine intellectual property considerations and trademark compliance. They ensure all legal requirements are addressed before final approval to prevent future disputes.

Supply Chain evaluates material availability, cost implications, and logistics considerations. They ensure designs are practical from a sourcing perspective and won’t create supply chain bottlenecks.

How Can You Streamline Feedback Collection and Implementation?

Efficient feedback systems accelerate revision cycles while improving prototype quality and stakeholder satisfaction.

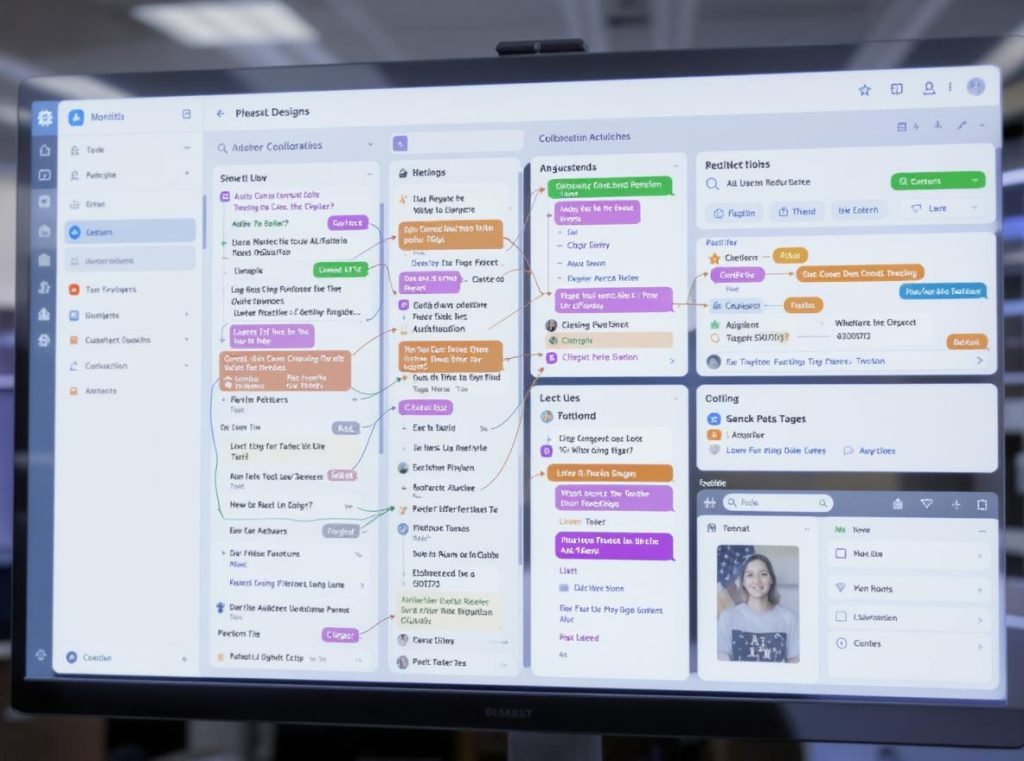

Streamline feedback collection using centralized platforms with visual annotation tools, automated workflows, and deadline tracking. This approach eliminates scattered communication while ensuring all stakeholders review current versions and provide structured input.

Centralized feedback platforms solve the chaos of scattered email communications. When all stakeholders can access the same system, they avoid reviewing outdated versions and can build upon each other’s suggestions more effectively.

Visual annotation tools prove especially valuable for packaging prototypes. Stakeholders can comment directly on packaging files, making their feedback crystal clear and actionable. This eliminates ambiguity that often leads to misunderstood requirements.

Effective feedback systems should include these essential features:

- Version control ensuring everyone reviews the most current iteration

- Automated reminders preventing delays through deadline tracking

- Status dashboards providing real-time visibility into approval progress

- Approval workflows routing files to appropriate stakeholders automatically

- Categorization tools organizing feedback by priority and source

Prioritize feedback based on impact and source relevance. Critical feedback affecting core functionality, legal compliance, or brand integrity requires immediate attention. High-priority suggestions that significantly improve user experience or production efficiency should be implemented when feasible.

Nice-to-have enhancements providing marginal improvements can be considered for future iterations if resources permit. When stakeholders provide contradictory input, escalate to designated decision-makers for resolution.

Set clear expectations about timelines, constraints, and decision-making processes. Transparent communication about when feedback will be reviewed and implemented helps prevent conflicts and maintains project momentum.

What Documentation Should You Maintain During Revisions?

Comprehensive documentation serves as the foundation for successful revision management and future project reference.

Maintain detailed documentation including version history with timestamps, approval records, feedback logs, change requests with rationale, test results, and production specifications. This comprehensive approach supports current decision-making while creating valuable resources for future projects.

Version history documentation should capture every modification made to prototypes, including who requested changes, why they were necessary, and what specific alterations were implemented. Use standardized naming conventions that indicate revision numbers, dates, and major change types.

Approval records must show who approved what and when, creating clear accountability trails. Document decision rationale explaining why specific changes were made or rejected. This information proves invaluable when similar issues arise in future projects.

Feedback logs should document all comments and their resolution status. Change requests require business justification and impact assessment to help prioritize implementation decisions.

Critical documentation elements include:

- Compliance verification documenting regulatory requirement fulfillment

- Test validation proving changes meet quality standards

- Change impact assessment showing how modifications affect other systems

- Stakeholder sign-offs confirming approval at each stage

- Production specifications detailing final manufacturing requirements

Maintain comprehensive audit trails essential for regulatory compliance and quality assurance. These records should be searchable and accessible to authorized personnel while maintaining appropriate security controls.

Implement automated backup systems protecting against data loss and integrate documentation with other business systems for seamless information flow.

How Do You Handle Conflicting Feedback from Multiple Stakeholders?

Conflicting feedback is inevitable when multiple departments review prototypes, but systematic approaches can resolve issues effectively.

Handle conflicting feedback by identifying root causes, implementing collaborative problem-solving sessions, using prioritization frameworks, and establishing clear escalation protocols. Document all conflicts and resolutions to prevent similar issues in future projects.

Conflicting feedback often stems from differing departmental priorities rather than fundamental disagreements. Sales teams focus on quick wins while design teams prioritize user experience. Timeline pressures create tension between thoroughness and speed.

Active listening helps understand stakeholder perspectives and concerns. Engage with feedback providers to understand the reasoning behind their suggestions and identify underlying issues driving conflicting positions.

Root cause analysis reveals whether conflicts stem from communication gaps, resource constraints, or genuinely incompatible requirements. This understanding guides appropriate resolution strategies.

Collaborative problem-solving brings conflicting parties together to explore solutions addressing multiple concerns simultaneously. Group discussions often reveal creative approaches that satisfy competing requirements.

Prioritization frameworks guide decision-making when conflicts cannot be resolved through collaboration:

- Impact vs. effort analysis evaluating feedback based on potential impact versus required resources

- Stakeholder influence mapping considering authority and expertise of feedback providers

- Strategic alignment prioritizing changes supporting overall business objectives

- Risk assessment evaluating consequences of implementing or ignoring specific feedback

Establish clear escalation protocols for conflicts requiring higher-level decision-making. Document all conflict resolution decisions and their rationale to prevent similar issues in future iterations.

What Technology Tools Can Improve Your Revision Process?

Modern packaging revision management relies on specialized software that streamlines collaboration and ensures accuracy.

Technology tools that improve revision processes include specialized packaging software like Artwork Flow, Filestage, and Approval Studio, integrated with project management platforms and communication tools. These solutions provide visual proofing, automated workflows, and comprehensive reporting capabilities.

Artwork Flow provides visual proofing with automated follow-ups and color-coded dashboards showing real-time project status. Features include direct file annotation, deadline management, and comprehensive reporting capabilities that eliminate manual tracking.

Filestage offers browser-based collaboration workspaces where stakeholders can share, discuss, and approve packaging artwork without email dependencies. Version control and contextual feedback tools ensure everyone works with current files.

Approval Studio delivers comprehensive review tools specifically designed for packaging, including barcode scanning, measurement verification, and regulatory compliance checking. These specialized capabilities address industry-specific requirements.

Advanced features for packaging-specific needs include:

- Barcode verification through automated scanning and validation

- Color management ensuring brand consistency across printing processes

- Regulatory compliance with built-in checks for labeling requirements

- Measurement tools providing digital verification of packaging dimensions

- 3D visualization showing how flat designs appear on finished packaging

Integration capabilities connect revision management systems with existing business tools:

| Integration Type | Benefits | Common Platforms |

|---|---|---|

| Design Software | Seamless file transfer | Adobe Creative Suite, Sketch, Figma |

| Project Management | Timeline coordination | Asana, Trello, Monday.com |

| Communication | Real-time updates | Slack, Microsoft Teams |

| Document Management | Centralized storage | SharePoint, Google Drive |

Effective systems integrate with design software, project management tools, communication platforms, document management systems, and enterprise resource planning solutions to create seamless workflows.

How Can You Measure and Improve Your Revision Process?

Continuous improvement requires systematic measurement and analysis of revision management performance.

Measure revision process effectiveness through time-based metrics like production cycle time, quality metrics such as defect rates, and efficiency indicators including revision frequency. Use this data to identify bottlenecks and implement targeted improvements.

Time-based metrics provide insight into process speed and bottleneck identification. Track production cycle time from initial design to final approval, revision cycle duration for implementing feedback, and approval stages where delays consistently occur.

Quality metrics indicate process effectiveness in delivering acceptable outcomes. Monitor defect rates showing percentage of packaging failing quality standards, error detection timing revealing how early problems are identified, and customer satisfaction scores reflecting packaging quality and functionality.

Efficiency metrics reveal resource utilization and process optimization opportunities. Measure revision frequency indicating iterations required for approval, resource utilization tracking cost per revision cycle, and process compliance showing adherence to established workflows.

Key performance indicators to track include:

- Average revision cycle time from feedback to implementation

- Percentage of revisions completed on schedule indicating process reliability

- Number of revisions per prototype showing process efficiency

- Stakeholder satisfaction ratings reflecting user experience quality

- Cost per revision cycle measuring resource efficiency

Implement continuous improvement frameworks through monthly reviews analyzing recent projects to identify bottlenecks and successful practices. Regular stakeholder feedback surveys reveal pain points and improvement suggestions.

Benchmark performance against industry standards and best practices to identify optimization opportunities. Technology evaluation assesses new tools and capabilities enhancing revision management efficiency.

What Are the Most Common Revision Management Mistakes to Avoid?

Learning from common mistakes prevents costly delays and quality issues that plague packaging projects.

Common revision management mistakes include starting packaging development too late, inadequate requirements definition, accepting unproducible design concepts, forcing aggressive timelines, and making faulty assumptions about component compatibility. These errors compound project complexity and extend timelines unnecessarily.

Late start timing creates compressed schedules when packaging development begins after product development completion. Running parallel processes allows better integration and more realistic timelines for thorough evaluation.

Inadequate requirements definition, particularly for labels and closures, creates expensive redesign cycles. Invest time upfront to fully think through all requirements and document detailed specifications.

Accepting unproducible marketing concepts without engineering feasibility assessment leads to costly discoveries late in the process. Validate technical feasibility before committing to design directions.

Forcing aggressive timelines often results in skipped validation steps and quality issues. Rushing suppliers to meet unrealistic deadlines compromises quality and creates expensive corrections later.

Additional critical mistakes to avoid:

- Faulty assumptions about component compatibility from previous projects

- Over-reliance on email for complex review processes despite available collaboration tools

- Insufficient training on new tools without adequate change management

- Tool proliferation using multiple disconnected systems creating information silos

- Poor version control lacking systematic file naming and access control approaches

Create standardized operating procedures and checklists for each revision stage to ensure consistent quality and prevent oversight mistakes. Regular training ensures all stakeholders understand current processes and available tools.

How Should You Handle Rush Revisions and Urgent Changes?

Rush revisions require modified processes that maintain quality while accelerating timelines under pressure.

Handle rush revisions by establishing emergency protocols, implementing parallel processing, prioritizing expert reviews, and maintaining automated quality checks. Balance speed with essential validation to prevent costly mistakes that create bigger problems.

Emergency protocols should include pre-defined processes activated when urgent changes are required. Streamlined approval chains and expedited review procedures reduce administrative delays without compromising essential oversight.

Resource allocation plans ensure predetermined arrangements with suppliers and internal teams can handle rush orders without compromising quality. These relationships prove invaluable when time pressure mounts.

Parallel processing conducts multiple validation steps simultaneously rather than sequentially to reduce overall timeline. This approach requires careful coordination but significantly accelerates revision cycles.

Rush revision protocols should include:

- Established emergency procedures with streamlined approval chains

- Resource allocation plans for handling urgent requirements

- Quality assurance shortcuts identifying which checks can be accelerated

- Communication escalation ensuring rapid stakeholder response

- Expert review prioritization focusing experienced reviewers on critical aspects

Maintain automated quality checks that rapidly validate barcode accuracy, color compliance, and regulatory requirements. These systems catch potential issues even under time pressure.

Post-rush validation implements additional quality checks after emergency production to identify and correct any issues that may have been missed during accelerated timelines.

Cost management for rush orders requires maintaining supplier relationships that can accommodate urgent requests at reasonable premiums while keeping critical materials in stock to avoid supply chain delays.

What Advanced Strategies Can Optimize Your Revision Process?

Advanced optimization strategies leverage data analytics and predictive insights to prevent problems before they occur.

Advanced strategies include predictive analytics using historical data to anticipate bottlenecks, automated workflow triggers routing files based on predefined criteria, template standardization reducing setup time, and resource allocation optimization based on project complexity assessment.

Predictive analytics analyze historical revision data to identify patterns indicating potential bottlenecks or quality issues. This information enables proactive intervention preventing problems before they impact project timelines.

Automated workflow triggers implement systems routing files to appropriate reviewers based on project type, complexity, or risk assessment. This automation reduces manual coordination while ensuring proper review coverage.

Template standardization creates reusable frameworks and checklists that reduce setup time and ensure consistency across projects. Standardized approaches prevent common oversights while accelerating project initiation.

Resource allocation optimization matches stakeholder involvement to project complexity and risk levels. High-risk projects receive more intensive review while routine revisions follow streamlined processes.

Advanced optimization techniques include:

- Artificial intelligence for automated quality checking and error detection

- Machine learning algorithms identifying patterns in successful revision processes

- Real-time dashboards providing instant visibility into process performance

- Integration automation connecting revision management with enterprise systems

- Predictive scheduling anticipating resource needs based on project pipelines

Building a culture of continuous improvement requires top management support recognizing packaging as a strategic tool. Interdisciplinary collaboration breaks down silos creating integrated approaches to packaging development.

Investment in technology and training ensures both appropriate tools and skilled users. Software selection should address specific organizational needs rather than generic solutions, supported by comprehensive training programs.

Summary

Effective packaging prototype revision management transforms chaotic processes into strategic competitive advantages. By implementing structured 11-step frameworks, centralizing feedback systems, defining clear stakeholder roles, and leveraging specialized technology tools, you can reduce revision cycles by 40% while maintaining quality standards and accelerating time-to-market.

Ready to revolutionize your packaging development process? Acreet specializes in streamlining complex packaging projects through proven revision management strategies. Our experienced team combines advanced technology with deep industry expertise to deliver custom packaging solutions that exceed expectations. Contact us today to discover how our systematic approach can accelerate your product launches while maintaining the highest quality standards. Send your inquiry now to transform your packaging development success.