Finding the right packaging manufacturer in China can feel overwhelming with thousands of options available. You need a partner who delivers quality products, meets deadlines, and understands your brand’s unique requirements without compromising on standards.

The key to finding a reliable packaging manufacturer in China lies in verifying business legitimacy, assessing production capabilities, and building strong communication channels. Focus on manufacturers with ISO 9001 certification, proven track records with international clients, and transparent quality control systems that meet global standards.

Let’s explore the essential steps to identify trustworthy packaging partners for your business success.

Table of Contents

ToggleWhat Makes a Packaging Manufacturer Truly Reliable?

Understanding reliability requires evaluating multiple factors that directly impact your business operations and product quality.

A reliable packaging manufacturer demonstrates ISO 9001 certification for quality management, operates from established industrial hubs, maintains financial stability with years of operation, and shows proven experience serving international clients with consistent quality standards.

Quality management systems form the foundation of reliability. ISO 9001 certification ensures consistent production quality and customer satisfaction through documented procedures and continuous improvement processes. For food packaging applications, look for ISO 22000 certification, which focuses specifically on food safety management systems.

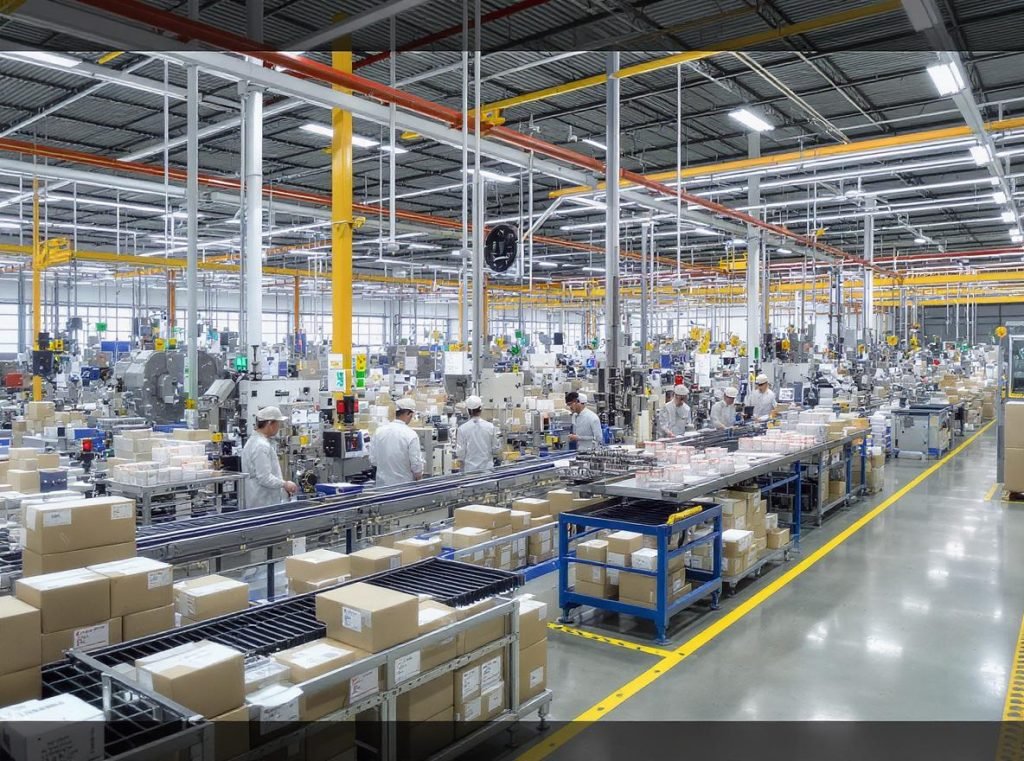

Production capabilities depend heavily on location and infrastructure. Reliable manufacturers typically operate from well-established industrial hubs including Guangdong province (accounting for over 30% of China’s packaging exports), Fujian’s Xiamen region (specializing in eco-friendly solutions), and Shanghai (offering advanced printing technologies for high-end customization).

Financial stability indicators include years of operation, steady revenue growth, and investment in modern equipment. Manufacturers with proven track records typically demonstrate their reliability through long-term partnerships with international clients and consistent business performance.

| Reliability Factor | Key Indicators | Business Impact |

|---|---|---|

| Quality Certifications | ISO 9001, ISO 22000, SQF Program | Ensures consistent production standards |

| Location & Infrastructure | Major industrial hubs, complete supply chains | Access to skilled workforce and materials |

| Financial Stability | Years of operation, steady growth, equipment investment | Protects against production disruptions |

| International Experience | Proven track record with global clients | Better understanding of export requirements |

How Do You Verify a Manufacturer’s Legitimacy?

Verification protects your business from fraudulent suppliers and ensures you’re working with genuine manufacturers.

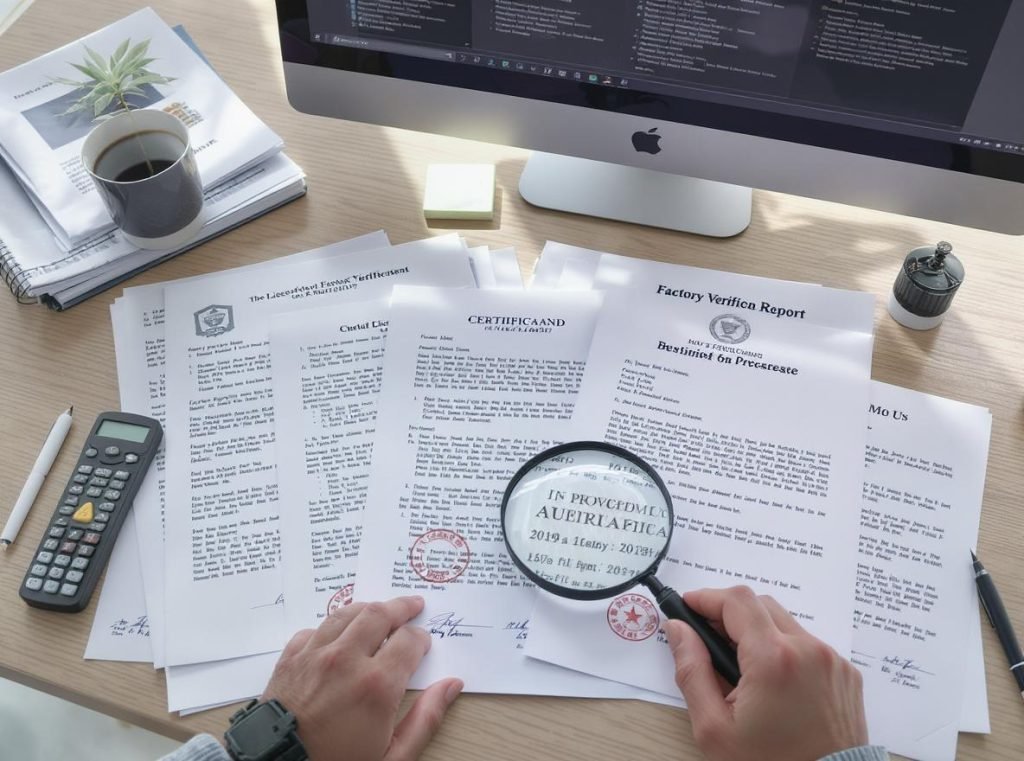

Verify legitimacy by requesting business licenses and registration documents, conducting factory audits through third-party services like SGS or TÜV Rheinland, and checking registered capital, establishment dates, and business scope details that specifically indicate manufacturing activities.

Business registration verification provides the foundation for legitimacy assessment. Request the manufacturer’s business license number and verify it through government databases. Check the registered capital, date of establishment, and scope of business, which should clearly indicate manufacturing activities if they claim to be a factory.

Factory audits offer crucial insights into actual production capabilities. Conduct on-site visits or arrange third-party factory audits to examine manufacturing facilities, testing equipment, packaging areas, and loading zones. Look for compliance with local labor laws and standards such as ISO 9001 and SA8000.

Third-party verification services provide comprehensive supplier assessment. Professional services like SGS, TÜV Rheinland, ExamineChina, and CFC (Cargo from China) offer detailed reports on manufacturers’ capabilities, quality control processes, and overall business practices. These services provide objective evaluation and reduce verification risks.

- Request and verify business license and registration documents

- Conduct on-site factory visits or arrange third-party audits

- Check registered capital, establishment date, and business scope

- Verify compliance with local labor laws and international standards

- Use professional verification services for comprehensive assessment

- Confirm the manufacturer’s ability to provide detailed operational information

What Are the Major Red Flags to Avoid?

Recognizing warning signs early prevents costly mistakes and protects your business from unreliable suppliers.

Major red flags include extremely low prices that seem unrealistic, demands for 100% prepayment via wire transfer, poor communication with vague responses, unwillingness to provide detailed information about manufacturing processes, and reluctance to sign contracts or agree on clear terms.

Pricing and payment warning signs often indicate fraudulent operations. Extremely low prices typically signal substandard materials or fraudulent suppliers. Avoid suppliers demanding 100% prepayment via wire transfer without secure payment platforms or structured payment terms. Legitimate suppliers work with reasonable payment schedules and secure payment methods.

Communication red flags reveal unprofessional or unreliable operations. Poor communication includes vague responses, delayed replies, or inconsistent information. Avoid suppliers who are unwilling to provide detailed information about their manufacturing processes, refuse factory visits, or are evasive about their business practices.

Quality and consistency problems indicate operational issues. Reject suppliers who provide inconsistent or poor quality samples or are hesitant to provide samples at reasonable prices. Be wary of manufacturers who frequently change quoted prices without valid reasons, as this indicates financial instability or unprofessionalism.

Contractual and legal concerns signal potential future problems. Avoid suppliers unwilling to sign contracts or agree on clear terms and conditions. Be cautious of companies showing lack of concern for intellectual property rights or offering to produce counterfeit products.

Where Should You Search for Packaging Manufacturers?

Knowing where to look significantly impacts the quality and reliability of manufacturers you’ll discover.

The most effective search strategies include using verified B2B platforms like Alibaba’s Gold Supplier program, attending major trade shows such as WEPACK Expo and ProPak China, and leveraging professional networks for referrals from businesses with successful sourcing experience.

B2B platforms provide extensive supplier databases with verification systems. Alibaba remains the most popular platform, with Gold Supplier status indicating third-party inspection company verification. Made-in-China and Global Sources offer comprehensive directories of packaging manufacturers with additional credibility features.

Trade shows enable direct manufacturer evaluation and relationship building. Major packaging trade shows in China include WEPACK Expo (Shanghai’s largest packaging fair with over 1,500 exhibitors), ProPak China (featuring 2,500+ exhibitors at Shanghai’s National Exhibition and Convention Center), PACKCON (China Packaging Container Expo), and Sino-Pack (International Exhibition on Packaging Machinery & Materials in Guangzhou).

Professional networks and referrals provide pre-vetted manufacturer recommendations. Leverage industry associations, business contacts, and referrals from other companies that have successfully sourced packaging from China. Consider working with sourcing agencies specializing in packaging with established relationships with verified manufacturers.

| Search Method | Key Features | Success Factors |

|---|---|---|

| B2B Platforms | Alibaba Gold Supplier, Made-in-China, Global Sources | Verification systems, supplier ratings |

| Trade Shows | WEPACK Expo, ProPak China, PACKCON, Sino-Pack | Direct evaluation, relationship building |

| Professional Networks | Industry associations, business referrals | Pre-vetted recommendations, trusted sources |

| Sourcing Agencies | Specialized packaging expertise | Established relationships, local knowledge |

How Do You Evaluate Manufacturing Capabilities?

Assessing production capabilities ensures manufacturers can meet your specific requirements and maintain consistent quality standards.

Evaluate manufacturing capabilities by examining maximum production output per work cycle, quality control systems with inspection procedures and testing protocols, technical capabilities including equipment age and maintenance programs, and compliance with relevant industry certifications.

Production capacity assessment determines their ability to handle your order volumes. Evaluate maximum production output per work cycle under standard circumstances and assess whether current production capacity can handle your volumes while maintaining quality standards. Consider their ability to scale production for increased demand and capacity allocation between existing and new customers.

Quality control systems reveal their commitment to consistent standards. Examine inspection procedures, testing protocols, and material verification systems. Look for advanced technology integration such as automated inspection systems, vision systems, and sensors for detecting defects. Verify material testing capabilities including tensile strength, barrier properties, and environmental resistance assessments.

Technical capabilities and equipment determine their competitive advantages. Assess their ability to handle different packaging materials, printing technologies, and customization options. Evaluate equipment age, maintenance programs, and investment in modern technology. Consider their research and development capabilities and ability to provide innovative packaging solutions.

Compliance and certifications provide objective quality assurance. Verify compliance with relevant industry standards including ISO 9001 for quality management, ISO 14001 for environmental management, and ISO 45001 for occupational health and safety. For food packaging, ensure compliance with HACCP principles and food safety regulations.

At Acreet, we maintain comprehensive quality control systems and hold relevant certifications to ensure our international clients receive consistent, high-quality packaging solutions that meet global standards.

What Questions Should You Ask Potential Manufacturers?

Asking the right questions reveals crucial information about manufacturer reliability, capabilities, and business practices.

Essential questions cover production capacity for specific requirements, quality control measures throughout production, business experience with international clients, payment terms and pricing structure, and typical lead times with ability to handle rush orders or schedule changes.

Production and quality questions assess operational capabilities. Ask about maximum production capacity for your specific packaging requirements, quality control measures throughout the production process, and their ability to provide samples meeting exact specifications. Inquire about relevant certifications for your product category and how they handle quality issues or defects in production.

Business and financial questions protect your investment. Inquire about their business history, experience with international clients, and references from customers in your industry. Ask about payment terms, pricing structure, insurance coverage for production and shipping, and their financial stability and business outlook.

Operational and logistical questions ensure realistic expectations. Ask about typical lead times for your order volumes, how they handle rush orders or production schedule changes, and shipping and logistics options. Inquire about packaging design and engineering services and their approach to intellectual property protection.

Communication and support questions reveal service quality. Ask about their customer service processes, technical support availability, and problem resolution procedures. Inquire about their English communication capabilities and dedicated international support teams.

- What is your maximum production capacity for our specific packaging requirements?

- What quality control measures do you have in place throughout production?

- Can you provide references from other customers in our industry?

- What are your payment terms and typical lead times?

- How do you handle intellectual property protection and confidentiality?

How Important Is Communication and Language Capability?

Effective communication forms the foundation of successful international partnerships and prevents costly misunderstandings.

Communication capability is crucial for preventing specification errors, ensuring accurate quality requirements, maintaining project timelines, and building long-term business relationships. Prioritize suppliers with clear English communication and prompt, professional response capabilities.

Language proficiency requirements directly impact project success. Poor communication can lead to misunderstandings, wrong products, and difficult resolution processes. Prioritize suppliers who can communicate clearly in English or your preferred language, as language barriers often result in specification errors and quality issues.

Communication channels and responsiveness indicate customer service priorities. Establish multiple communication channels including email, phone, and video conferencing capabilities. Test the manufacturer’s responsiveness during initial communications, as prompt and professional responses indicate good customer service practices.

Cultural considerations enhance partnership success. Understanding Chinese business culture, particularly the concept of Guanxi (relationship-building), is essential for long-term success. Chinese manufacturers value personal relationships over formal transactions, so invest time in building trust through regular communication, meetings, and social interactions.

Professional communication skills indicate international experience and business sophistication. Manufacturers with strong English communication typically have more experience with international clients and better understand global business practices, leading to smoother collaboration and fewer misunderstandings.

What Role Do Certifications Play in Manufacturer Selection?

Certifications provide objective evidence of manufacturer capabilities, quality standards, and compliance with international requirements.

Certifications demonstrate manufacturer commitment to quality, safety, and environmental responsibility. Key certifications include ISO 9001 for quality management, ISO 22000 for food safety, BRCGS Packaging Standard for global recognition, and ISO 14001 for environmental management systems.

Quality management certifications ensure consistent production standards. ISO 9001 serves as the foundation for quality management systems, ensuring consistent production quality and customer satisfaction through established processes for quality control, staff training, and continuous improvement.

Industry-specific certifications provide specialized compliance assurance. For food packaging, ISO 22000 certification covers food safety management throughout the supply chain. The BRCGS Packaging Standard is recognized globally and ensures good manufacturing practices for packaging producers across sectors. For pharmaceutical packaging, ISO 15378 integrates quality management with specific pharmaceutical requirements.

Environmental and safety standards demonstrate responsible manufacturing. ISO 14001 certification shows commitment to environmental management and sustainability practices. ISO 45001 ensures occupational health and safety management systems protect workers. These certifications indicate a responsible manufacturer committed to sustainable and ethical practices.

The SQF (Safe Quality Food) Program is recognized through the Global Food Safety Initiative and ensures the highest food safety standards for packaging manufacturers serving the food industry.

| Certification Type | Key Standards | Industry Applications |

|---|---|---|

| Quality Management | ISO 9001, continuous improvement processes | All packaging applications |

| Food Safety | ISO 22000, SQF Program, HACCP compliance | Food and beverage packaging |

| Environmental | ISO 14001, sustainability practices | Eco-friendly packaging solutions |

| Safety Standards | ISO 45001, worker protection systems | All manufacturing operations |

How Do You Assess Financial Stability and Business Health?

Financial stability protects your business from production disruptions and ensures your manufacturer can fulfill long-term commitments.

Assess financial stability by reviewing business registration documents, financial statements including balance sheets and income statements, working capital ratios, market position, and investment in modern equipment and technology upgrades that demonstrate growth commitment.

Financial documentation review provides insights into business health. Request and review the manufacturer’s financial statements, including balance sheets, income statements, and cash flow statements. Look for consistent revenue growth, healthy profit margins, and positive cash flow over multiple years. Assess their debt-to-equity ratio and overall financial leverage to ensure stability.

Business performance indicators reveal operational efficiency. Evaluate the manufacturer’s working capital, current ratio, and quick ratio to assess their ability to meet short-term obligations. A current ratio above 1.0 generally indicates good liquidity, while a quick ratio close to 1.0 suggests the company can meet immediate liabilities.

Market position and reputation assessment identifies stable partners. Research the manufacturer’s market position, customer base, and industry reputation. Look for signs of growth, investment in new technology, and expansion into new markets. Check for any legal issues, regulatory violations, or negative publicity that might affect their business stability.

Investment in infrastructure and technology demonstrates long-term commitment. Manufacturers who regularly invest in new equipment, facility upgrades, and technology improvements typically have better financial health and long-term vision for sustainable growth.

What Should You Expect During the Sample Phase?

The sample phase provides crucial insights into manufacturer capabilities and sets expectations for production quality standards.

During the sample phase, expect comprehensive sample evaluation for quality and functionality, willingness to accept reasonable sample fees, detailed documentation and feedback processes, and responsiveness to modification requests that demonstrate their customization capabilities.

Sample evaluation process reveals true manufacturing capabilities. Request samples that meet your exact specifications and be prepared to pay for them, as free samples may not represent the manufacturer’s true capabilities. Evaluate samples for quality, functionality, and design to ensure they meet your requirements and industry standards.

Testing and verification ensure product performance. Conduct comprehensive testing on samples including durability testing, consistency checks, and adherence to specifications. Test samples under various conditions to ensure they will perform as expected during shipping and storage. Compare samples from multiple manufacturers to make informed decisions.

Documentation and feedback establish clear expectations. Document all sample evaluations and provide detailed feedback to manufacturers. This helps establish clear expectations and demonstrates your commitment to quality. Use the sample phase to assess the manufacturer’s responsiveness to feedback and their ability to implement requested changes.

Professional sample management indicates business sophistication. Reliable manufacturers provide structured sample processes, clear timelines, and detailed documentation. They should be willing to make reasonable modifications and provide technical explanations for any limitations or recommendations.

At Acreet, we provide comprehensive sample services with detailed documentation and technical support to ensure our clients can make informed decisions about their packaging requirements.

How Do You Build Long-Term Partnerships?

Successful partnerships require ongoing commitment to mutual benefit and understanding of Chinese business culture.

Build long-term partnerships by developing Guanxi (relationship-based business connections) through regular communication and factory visits, establishing clear performance monitoring systems, providing mutual benefits through volume growth and product development collaboration, and maintaining proper contract management with regular reviews.

Relationship development strategies focus on building trust and understanding. Focus on building Guanxi through regular communication, factory visits, and social interactions. Show genuine interest in the manufacturer’s business and culture, and invest time in developing personal relationships with key contacts. This approach leads to better cooperation, priority treatment, and problem-solving support.

Performance monitoring and improvement ensure continuous quality. Establish key performance indicators (KPIs) to monitor the manufacturer’s performance over time. Regular performance reviews help identify areas for improvement and maintain high standards. Provide constructive feedback and work collaboratively to address any issues that arise.

Mutual benefits and growth create sustainable partnerships. Develop partnerships that benefit both parties through volume growth, product development collaboration, and long-term commitments. Support your manufacturers’ growth by providing forecasts, introducing them to other businesses, and working together on innovation projects.

Contract management and legal protection ensure fair relationships. Ensure all agreements are properly documented with clear terms covering quality standards, delivery schedules, payment terms, and intellectual property rights. Regular contract reviews and updates help maintain fair and beneficial relationships as business needs evolve.

| Partnership Element | Key Activities | Long-term Benefits |

|---|---|---|

| Relationship Building | Regular communication, factory visits, cultural understanding | Better cooperation, priority treatment |

| Performance Monitoring | KPIs, regular reviews, constructive feedback | Continuous improvement, maintained standards |

| Mutual Growth | Volume increases, product development, innovation | Sustainable partnerships, shared success |

| Contract Management | Clear terms, regular reviews, legal protection | Fair relationships, risk mitigation |

Summary

Finding a reliable packaging manufacturer in China requires systematic evaluation of business legitimacy, production capabilities, and communication systems. Focus on manufacturers with ISO 9001 certification, proven international experience, and transparent quality control processes. Avoid red flags like unrealistic pricing, poor communication, or reluctance to provide documentation.

Contact Acreet today to discuss your custom packaging requirements and experience the difference of working with a certified, financially stable manufacturer committed to building long-term partnerships and delivering consistent quality for your business success.