Selecting the wrong pouch size can lead to wasted materials, poor product presentation, and unhappy customers. Many brands struggle with packaging that’s either too large or too small for their products, resulting in inefficient storage and shipping costs that directly impact profitability.

The key to choosing the right pouch size lies in understanding the difference between net weight and net volume, calculating your product’s bulk density, and considering fillable space limitations. This process involves measuring your product’s actual volume requirements, accounting for sealing margins, and testing with sample packs before committing to production quantities.

Let’s explore the essential factors that will help you select the perfect pouch size for optimal packaging performance and cost efficiency.

Table of Contents

ToggleWhat’s the Difference Between Net Weight and Net Volume?

Understanding this fundamental distinction is crucial for making informed packaging decisions that affect both cost efficiency and customer satisfaction.

Net weight refers to the actual mass of your product measured in grams, kilograms, or ounces, while net volume measures the three-dimensional space your product occupies in milliliters, liters, or cubic units. Products with identical weights can have vastly different volume requirements.

This difference becomes critical when sizing pouches. Eight ounces of ground coffee occupies significantly less space than eight ounces of whole bean coffee due to differences in particle size and air gaps. Similarly, protein powder requires less volume than granola of the same weight, and pet kibble needs more space than freeze-dried snacks.

Consider these real-world examples that illustrate weight versus volume disparities:

- 8 oz of ground coffee = compact volume requirement

- 8 oz of whole bean coffee = 40% larger volume requirement

- 8 oz of protein powder = medium density packing

- 8 oz of popcorn = significantly larger volume due to irregular shapes

For microgreens packaging, industry professionals follow a practical rule: for every eight ounces of packaging volume, use one ounce of microgreens by weight. However, this varies by crop density—sunflower shoots require more weight per volume than basil microgreens due to their higher density.

How Do You Calculate Your Product’s Actual Volume Requirements?

Proper volume calculation prevents both overpacking and underpacking situations that can damage your brand reputation and increase operational costs.

To calculate product volume accurately, use geometric formulas for regular shapes, conduct physical testing with sample packs, and account for sealing margins and equipment limitations. The most reliable method combines mathematical calculations with hands-on testing.

Basic Volume Calculation Formulas:

For flat pouches, volume equals width × height for two-dimensional products. Stand-up pouches require length × width × height calculations. Gusseted pouches need special consideration for expansion when filled by measuring the opened gusset from front to back.

Physical Testing Protocol:

The most accurate method for determining volume needs involves physical testing with sample packs. This hands-on approach allows you to assess not just fit, but also appearance and customer appeal. Many packaging companies offer free sample packs containing various sizes for testing purposes.

Step-by-Step Volume Assessment:

| Step | Method | Purpose |

|---|---|---|

| 1. Measure product density | Fill container, weigh, calculate | Understand space requirements |

| 2. Test sample pouches | Use actual product in different sizes | Validate calculations |

| 3. Account for settling | Observe product behavior over time | Prevent overfilling issues |

| 4. Add safety margins | Include 10-15% extra space | Ensure proper sealing |

For irregular-shaped products, fill the pouch with water or a similar substance, measure the amount used, and calculate volume based on that measurement. This provides practical accuracy when standard formulas are insufficient.

What Are the Industry-Standard Pouch Sizes for Different Products?

Industry standards provide reliable starting points, but understanding capacity relationships helps you make better customization decisions for your specific products.

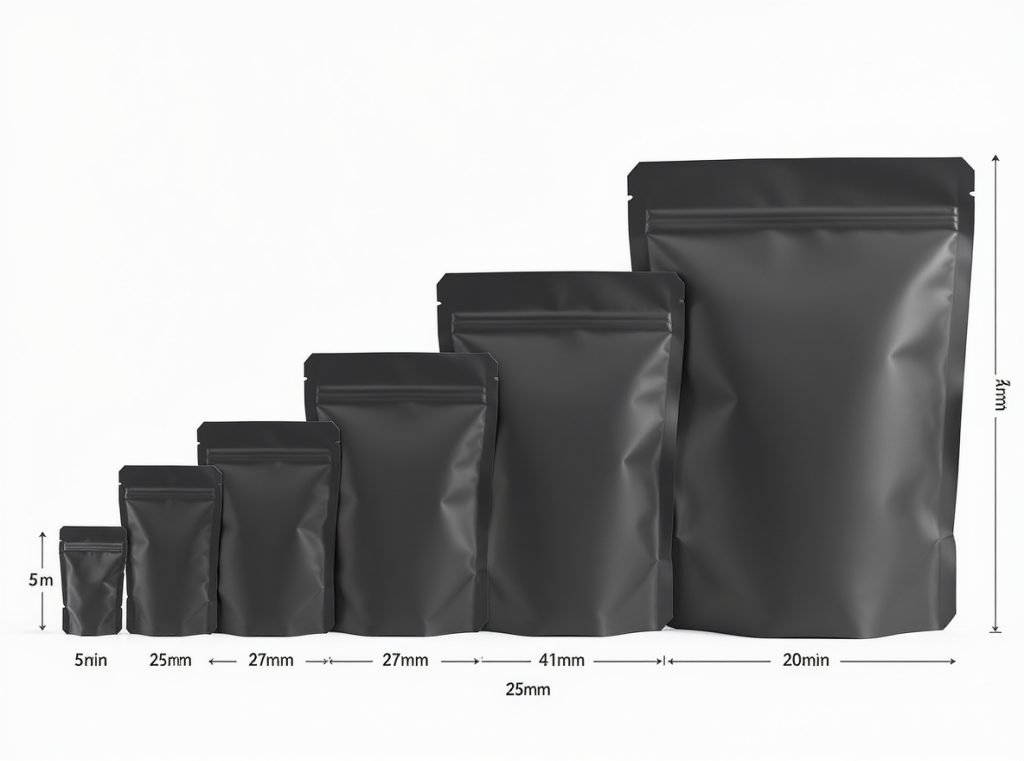

Standard stand-up pouch sizes range from small 8×13cm options for single servings to large 20×30cm sizes for bulk products, with specific capacity guidelines varying by product density and intended use.

Common Standard Sizes and Capacities:

Industry-standard sizes include 8×13cm pouches (50g powder capacity) for single servings and samples, 10×15cm pouches (100-150g powder capacity) for coffee and tea, 13×20cm pouches (200-250g powder capacity) for pet food and granola, 16×24cm pouches (450-500g powder capacity) for chips and nuts, and 20×30cm pouches (1kg powder capacity) for large quantity dry goods.

Product-Specific Sizing Guidelines:

Different product categories require tailored approaches based on density and consumer usage patterns:

- High-density products (nuts, coffee beans): Use smaller pouches relative to weight

- Low-density products (chips, popcorn): Require proportionally larger pouches

- Powder products (protein, flour): Need consideration for settling and compaction

- Granular products (pet food, cereal): Account for irregular shapes and air pockets

Recommended Size Categories:

| Product Category | Suggested Dimensions | Weight Capacity | Best Applications |

|---|---|---|---|

| Sample/Single serve | 5″×8″×3″ | Up to 150g | Trial sizes, portion control |

| Regular consumer | 7″×10″×4″ | 150g-500g | Standard retail packages |

| Family size | 9″×12″×4.5″ | 500g-1kg | Multi-serving packages |

| Bulk/Commercial | 12″×15″×6″ | 1kg-2kg+ | Wholesale, food service |

How Does Bulk Density Impact Your Pouch Size Selection?

Product density directly determines the relationship between weight and volume requirements, making it often the deciding factor in pouch size selection.

Bulk density—defined as mass per unit volume—determines how much space a product actually requires. High-density products like salt take up less volume than low-density products like popcorn, even at identical weights, affecting packaging equipment flow, sealing requirements, and transportation efficiency.

Understanding Density Classifications:

High-density products flow differently through filling machinery compared to low-density products. Different densities impact seal integrity, storage efficiency, and transportation costs. Accurate density calculations optimize warehouse space and reduce shipping expenses.

Dense products (nuts, dried fruits, hardware) pack efficiently with minimal air gaps and settle predictably during shipping. Medium-density products (granulated items, some powders) require moderate headspace and may experience some settling during transport.

Low-density products (cereals, chips, lightweight items) demand careful volume calculations because irregular shapes create significant air pockets that affect fill patterns.

Density Calculation for Large Pouches:

To determine appropriate sizing for bulk packaging: Multiply bag volume (m³) × material density (kg/m³) = material weight capacity (kg). This formula helps avoid underestimating capacity, which can lead to package failures, or overestimating, which results in inefficient packaging choices.

Practical Density Assessment:

- Measure a known volume of your product

- Weigh the sample and calculate density

- Compare results with similar products in your category

- Test how density affects filling and sealing processes

- Document variations between product batches

What Critical Factors Extend Beyond Simple Volume Calculations?

Successful pouch sizing involves multiple considerations that significantly impact both functionality and cost efficiency beyond basic volume requirements.

Beyond volume, you must consider fillable space limitations, sealing requirements, equipment compatibility, and regulatory compliance to ensure your pouch size supports both operational efficiency and market requirements.

Fillable Space vs. Overall Dimensions:

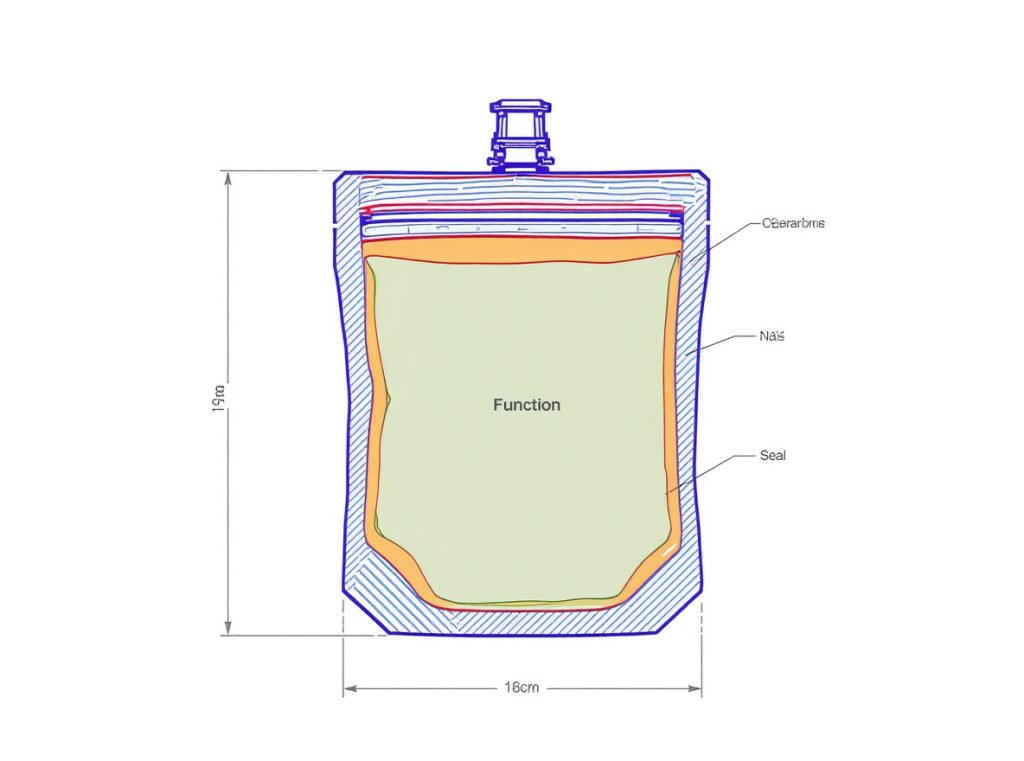

The fillable area differs from overall pouch dimensions. Key considerations include seal area space above the zipper that cannot hold product, zipper clearance room needed for proper closure, tear notches and hang holes that reduce available space, and heat seal margins requiring additional clearance for proper sealing.

A critical insight: A 6×8 inch pouch will not necessarily accommodate a 5×6 inch product due to these space limitations.

Equipment Compatibility Requirements:

Your filling method significantly impacts size requirements. Hand-filling offers more flexibility in pouch selection, while automatic filling requires specific pouch thickness and size tolerances. Force considerations show that automated equipment generates more stress than manual filling.

Additional Space Considerations:

| Factor | Impact | Requirement |

|---|---|---|

| Seal margins | Prevents seal contamination | 6-8mm minimum clearance |

| Zipper clearance | Ensures proper closure | Product-free zone above zipper |

| Tear notches | Reduces fillable area | Account for feature placement |

| Hang holes | Affects available space | Consider position and size |

Brand Positioning and Marketing:

Premium products often use larger pouches with more headspace to create a luxury feel and better shelf presence. Value products typically maximize fill efficiency to demonstrate good value proposition to cost-conscious consumers.

How Should You Test and Validate Your Pouch Size Decision?

Proper validation prevents costly production mistakes and ensures your packaging performs reliably under real-world conditions.

Effective validation requires sample testing with actual products, statistical analysis following industry standards, environmental conditioning, and comprehensive documentation to confirm your pouch size meets all functional and regulatory requirements.

Sample Testing Protocol:

Always order sample packs before committing to production quantities. This allows you to test actual product fit and appearance, evaluate seal integrity with your specific product, assess shelf presentation and customer appeal, and compare different sizes and formats side-by-side.

Statistical Validation Standards:

For commercial validation, follow proper statistical sampling with a minimum confidence level of 95% (may be as high as 98%), ensure sample size significance as larger samples provide more reliable data, maintain zero-failure acceptance since most package validation requires no failures in testing, and maintain documentation requirements by recording all observations and measurements.

Testing Environment Controls:

Establish consistent testing conditions including environmental conditioning for 24 hours at 23°C and 50% relative humidity, regular equipment calibration to ensure accurate results, compression testing to verify pouch strength under stacking conditions, and seal integrity testing for heat seal strength and barrier properties.

Performance Validation Metrics:

| Test Parameter | Target Standard | Measurement Method |

|---|---|---|

| Fill efficiency | 85-90% capacity utilization | Volume used ÷ available volume |

| Seal strength | Zero failure rate | Pressure and peel testing |

| Compression resistance | No deformation | Stacking load simulation |

| Environmental stability | No property changes | Temperature/humidity cycling |

Document all testing results systematically and use this data to refine specifications before committing to full production runs.

What Are the Most Common Pouch Sizing Mistakes to Avoid?

Learning from frequent errors saves significant time, money, and prevents customer satisfaction issues that can permanently damage brand reputation.

The most critical mistakes include using generic ill-fitting packaging, making sizing decisions based on weight alone, overfilling pouches during production, and failing to account for sealing area requirements and material compatibility issues.

Critical Sizing Errors:

Using generic, ill-fitting packaging ranks as the most common mistake. This leads to oversized packaging that wastes materials and increases shipping costs while allowing product damage from movement, undersized packaging that prevents proper sealing and causes customer dissatisfaction, and a one-size-fits-all approach that proves inefficient for diverse product lines.

Production and Sealing Mistakes:

Common operational errors include overfilling pouches which prevents proper sealing and increases failure risk, inadequate air removal that causes product spoilage and bag expansion, incorrect heat settings resulting in weak or damaged seals, and contaminated seal areas where moisture or product residue prevents proper closure.

Material Selection Errors:

Material-related mistakes to avoid include selecting inappropriate materials as not all materials suit every product type, using inadequate thickness that provides insufficient strength for product weight, wrong barrier properties that give incorrect moisture or gas protection, and poor compatibility due to material interactions with specific products.

Quality Control Oversights:

- Inconsistent density measurements leading to variable fill levels

- Inadequate testing protocols that miss real-world failure modes

- Poor documentation practices that prevent learning from mistakes

- Insufficient supplier communication causing specification misunderstandings

Prevention requires systematic approach, comprehensive testing, clear documentation, and strong supplier relationships.

How Can Professional Packaging Partners Optimize Your Pouch Selection?

Experienced packaging manufacturers provide specialized expertise and advanced capabilities that significantly improve sizing decisions while reducing risks and costs.

Professional packaging partners like Acreet offer industry expertise, advanced testing facilities, system integration capabilities, and comprehensive optimization services that help achieve the perfect balance of functionality, cost efficiency, and brand positioning.

Technical Expertise Advantages:

Working with experienced packaging partners provides significant advantages including industry expertise with deep knowledge of specific market requirements, system integration through seamless coordination with existing equipment, engineering support offering technical expertise for complex challenges, and testing capabilities providing advanced validation and optimization services.

Selection Criteria for Partners:

Choose packaging partners based on relevant industry experience with a proven track record in your sector, integration capabilities to work with existing systems, engineering depth through strong technical support teams, and customization options offering flexibility for unique requirements.

Comprehensive Optimization Services:

Professional partners offer comprehensive optimization through value chain analysis with complete assessment of packaging costs and efficiency, custom solution development with tailored designs for specific needs, process optimization for improved production and logistics efficiency, and sustainability integration with environmentally responsible packaging solutions.

Measurable Benefits:

Professional optimization typically delivers reduced material costs through right-sizing that eliminates waste, improved efficiency via streamlined packaging processes, enhanced protection for better product integrity during transport, and brand enhancement through professional appearance and functionality.

Partnership Value Proposition:

| Service Area | Benefit | Impact |

|---|---|---|

| Technical analysis | Right-size calculations | Reduced material waste |

| Testing capabilities | Validation confidence | Fewer production issues |

| Industry knowledge | Best practice application | Faster time to market |

| Custom solutions | Perfect fit design | Enhanced brand positioning |

The investment in professional packaging consultation typically pays for itself through improved efficiency, reduced waste, and enhanced customer satisfaction.

Summary

Choosing the right pouch size requires understanding the difference between net weight and net volume, calculating bulk density impacts, and accounting for fillable space limitations. Success depends on comprehensive testing with sample packs, avoiding common sizing and sealing mistakes, and leveraging professional expertise for validation and optimization.

Ready to optimize your product packaging with expert guidance? Contact Acreet today for professional pouch sizing consultation and custom packaging solutions. Our experienced team provides comprehensive testing, technical analysis, and tailored recommendations to ensure your packaging perfectly balances functionality, cost efficiency, and brand positioning for maximum market success.