Sourcing products from China offers tremendous opportunities, but quality concerns and geographical distance create significant challenges for international businesses. Without proper oversight, you risk receiving defective products, damaged brand reputation, and costly returns that can devastate your bottom line.

Yes, hiring a third-party inspection service in China is essential for most businesses sourcing products internationally. Industry experts overwhelmingly agree that these services provide independent quality control, reduce financial risks, and ensure product standards are met before shipment. While costing $149-320 per man-day, inspections prevent significantly larger losses from defective products and protect brand integrity.

Let’s explore everything you need to know about making this crucial decision for your business success.

Table of Contents

ToggleWhat Are Third-Party Inspection Services in China?

Understanding third-party inspection services is essential for making informed sourcing decisions. These services act as your independent eyes and ears when you can’t be physically present at manufacturing facilities.

Third-party inspection services are independent professional organizations that evaluate and verify products, processes, or services between buyers and sellers. Unlike factory quality control departments that answer to factory management, these services provide completely unbiased assessments to ensure products meet specific standards, specifications, and contractual requirements.

These services operate as professional safeguards by providing objective quality verification without any vested interest in cutting corners or hiding defects. Third-party inspectors work exclusively for the buyer’s interests, ensuring complete independence from supplier influence.

The inspection process involves measuring, testing, examining, or gauging products against predetermined standards and regulations. Professional inspectors follow pre-established checklists based on your product specifications and compare results with requirements to determine compliance.

Third-party inspection services typically offer three core areas of quality control that address different stages of production:

- Review Inspections: Check products for defects before they leave the supplier in China

- Process Inspections: Investigate ongoing quality issues during production to identify root causes and suggest remedies

- Preventative Inspections: Verify supplier legitimacy and production processes, including raw material sources

| Service Type | Purpose | Typical Duration |

|---|---|---|

| Pre-production Inspection | Verify raw materials and initial setup | Half day |

| During Production Inspection | Monitor manufacturing progress | Full day |

| Pre-shipment Inspection | Final product verification | Full day |

| Container Loading Supervision | Ensure proper packing and loading | Half day |

How Much Do Third-Party Inspection Services Cost in China?

Cost transparency helps you budget effectively for professional inspection services. The pricing structure follows industry-standard “man-day” calculations that are straightforward and predictable.

Third-party inspection services in China operate on a “man-day” pricing model, costing between $149-320 per man-day as of 2025. The average cost ranges from $200-300 per man-day, with all-inclusive pricing covering service fees, travel costs, ground transportation, up to 8-12 hours of inspection time, detailed reports with photos, and pre/post-inspection follow-up.

Leading inspection companies offer competitive and transparent pricing structures. Here’s the current market breakdown for established providers:

Popular Service Rates:

- AQI Service: $198 per man-day in China

- China Inspection Services: $248 per man-day

- V-Trust: $268 per man-day

- Bureau Veritas: $288 per man-day

- Jonble: $299 per man-day

Subscription Plans provide cost savings for frequent users:

- Tetra Inspection: $189 per inspection (monthly plan) or $158 per inspection (annual plan)

- KRT Audit Corp: New customer rates as low as $195 per man-day

Additional fees may apply for specific requirements:

- Extra reports: $15 each

- Overtime work: $15 per hour after 6 PM

- Official holiday work: +$50 per man-day

The all-inclusive pricing model ensures no hidden costs, making it easy to calculate total inspection expenses. Consider this investment against potential losses from defective products – a single container of defective goods can cost tens of thousands in returns, replacements, and damaged customer relationships.

What Are the Main Benefits of Using Third-Party Inspections?

Professional inspection services deliver measurable value that extends far beyond basic quality checking. These benefits transform sourcing operations and protect business interests.

Third-party inspections provide objective assessment, substantial cost savings through risk reduction, enhanced product quality consistency, increased supplier accountability, regulatory compliance verification, and peace of mind for remote operations. They prevent revenue-reducing incidents like shipment delays, material waste, and product returns.

Objective and Unbiased Assessment represents the cornerstone benefit. Third-party inspectors provide completely independent evaluations with no vested interest in cutting corners or hiding defects. Unlike factory quality control staff accountable to factory management, third-party inspectors work exclusively for buyer interests.

Cost Savings and Risk Reduction deliver substantial long-term value despite initial investment. Professional inspections prevent costly recalls, rework, and reputational damage by identifying and rectifying quality issues early in production rather than after customer delivery.

Enhanced Product Quality and Consistency ensures products meet required specifications and quality standards before shipment. This reduces defective rates and ensures only products meeting Acceptable Quality Limits (AQL) reach the market, preventing issues like cracks, glazing problems, or design inconsistencies.

Key operational benefits include:

- Supplier Accountability: Manufacturers become more accountable for quality standards when independent assessments are conducted

- Regulatory Compliance: Ensures products meet international standards and regulatory requirements for export

- Documentation: Provides inspection certificates required for import entry in many countries

- Remote Confidence: Delivers confidence in product quality despite geographical distance and language barriers

The investment in professional inspection services pays dividends through prevented defects, maintained customer satisfaction, and protected brand reputation. Early detection prevents cascading problems that become exponentially more expensive to resolve after shipment.

What Types of Products Need Third-Party Inspection Most?

Not all products require identical inspection oversight. Understanding which categories benefit most from professional inspection helps optimize your quality control investment and risk management strategy.

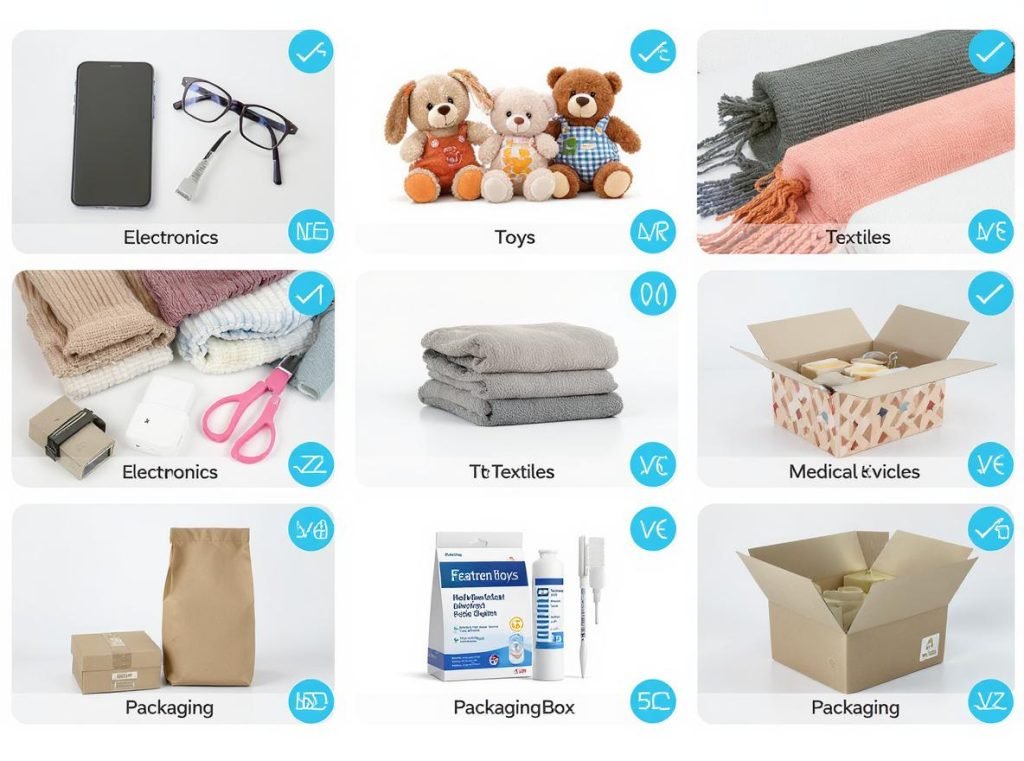

High-risk product categories requiring third-party inspection include consumer electronics, toys and children’s products, textiles and apparel, medical devices, food packaging materials, and any products with safety implications, complex specifications, high value, or regulatory compliance requirements.

Safety-Critical Products demand professional inspection regardless of cost considerations. Consumer goods and electronics require stringent safety testing and functionality verification. Toys and children’s products must meet strict safety regulations and compliance standards. Medical devices need verification before reaching healthcare markets.

Complex Specification Products with multiple components, intricate assembly requirements, or precise measurements benefit significantly from expert evaluation. Items requiring technical specifications or specialized components have numerous potential failure points that trained inspectors can identify before shipment.

High-Value and High-Volume Orders justify inspection costs through significant financial risk mitigation. Large investments warrant additional protection, as order values make inspection fees minimal compared to potential losses from defective products.

| Product Category | Risk Level | Inspection Priority | Key Focus Areas |

|---|---|---|---|

| Electronics | High | Essential | Safety testing, functionality |

| Toys & Children’s Products | High | Essential | Safety regulations, compliance |

| Medical Devices | Critical | Mandatory | Regulatory standards |

| Food Packaging | High | Essential | Material safety, compliance |

| Textiles & Apparel | Medium | Recommended | Material quality, construction |

| Home Goods | Medium | Recommended | Functionality, durability |

Regulated Market Products destined for markets with strict regulatory requirements (FDA, CE marking, safety certifications) need verification of compliance before shipment. Food packaging materials must meet specific national food safety standards in both China and destination countries.

New Supplier Relationships require additional oversight until reliability is established. Professional inspection provides crucial verification of capabilities and quality standards, especially important during initial relationship-building phases.

Private Label and Brand Products face higher reputational risks from quality issues. Companies selling under their own brand names need inspection protection for brand integrity and customer loyalty through consistent quality standards.

How Do You Choose the Right Inspection Company?

Selecting the appropriate inspection service provider significantly impacts your quality control program effectiveness. Several critical factors determine the best choice for your specific needs and requirements.

Choose inspection companies based on industry experience, geographic coverage, professional certifications, reporting quality, transparent pricing, and proven track records in your product category. Look for providers with local presence in your supplier regions, relevant accreditations, and comprehensive service capabilities.

Define Your Specific Needs before evaluating providers. Clearly identify your product type, quality standards, and inspection requirements. Different products require different expertise – electronics need different checks than clothing or furniture. Determine whether you need pre-production, during-production, or pre-shipment inspections.

Verify Qualifications and Certifications by looking for companies with industry-recognized credentials such as ISO 9001 (quality management systems), ISO 17020 (inspection body competency), and relevant industry-specific accreditations. Check if inspectors have ASQ (American Society for Quality) or AQSIQ qualifications.

Assess Industry Experience and Expertise by choosing companies with proven experience in your specific product category. Review their track record, case studies, and client testimonials. Companies should demonstrate deep knowledge of your industry’s quality standards and regulatory requirements.

Essential evaluation criteria include:

- Geographic Coverage: Local presence in manufacturing regions for quick response

- Service Capabilities: Comprehensive inspection types and specialized testing

- Technology Integration: AI-driven visual inspection systems and digital reporting platforms

- Communication: English-speaking staff and prompt, clear responses

- Pricing Transparency: All-inclusive rates with no hidden fees

Evaluate Service Coverage by ensuring companies maintain local presence in your manufacturing regions. Leading providers like HQTS, V-Trust, and Bureau Veritas maintain offices across major Chinese manufacturing cities including Shenzhen, Shanghai, Guangzhou, and Dongguan.

Review Reporting Quality by assessing comprehensiveness of inspection reports. Good inspection companies provide detailed reports with photos, statistical analysis, and clear recommendations within 12-24 hours of service completion. Request sample reports to evaluate detail level and clarity of findings.

Leading inspection companies now utilize AI-driven visual inspection systems, statistical process control, and digital reporting platforms. These technologies improve accuracy and efficiency compared to traditional manual-only approaches, providing better value for your investment.

When Should You Skip Third-Party Inspections?

While third-party inspections offer significant benefits, certain specific situations may not justify the cost and complexity. Understanding these exceptions helps optimize your quality control strategy and resource allocation.

You may consider reducing inspection frequency for established supplier relationships with proven quality records, low-risk simple products with minimal specifications, or when implementing skip-lot inspection strategies for trusted suppliers. However, industry experts strongly advise against completely eliminating inspections, even for reliable suppliers.

Established, Trusted Supplier Relationships may warrant skip-lot inspections when working with suppliers who have consistently demonstrated high quality over extended periods. This approach involves inspecting selected shipments while skipping others, suitable for companies with long-term relationships and few historical quality issues.

Low-Risk, Low-Value Products with simple construction and minimal quality risks might not justify full inspection costs. However, even small defects can lead to negative reviews and customer complaints, so this decision requires careful risk assessment against potential reputation damage.

Reliable Suppliers with Proven Track Records who have consistently met quality standards and maintain robust internal quality control systems might qualify for reduced inspection frequency. This strategy should be based on documented performance history and statistical quality data, not assumptions or supplier promises.

Strategic inspection reduction approaches include:

- High-Frequency Orders: Companies making frequent orders of identical products from proven suppliers might implement reduced inspection schedules

- Internal Quality Teams: Organizations with in-house quality control teams stationed near suppliers might rely on internal inspections

- Statistical Sampling: Use statistical methods to determine appropriate inspection frequency based on supplier performance data

| Situation | Risk Level | Recommendation | Considerations |

|---|---|---|---|

| Proven suppliers | Medium | Periodic verification | Document performance history |

| Low-value products | Low | Selective inspection | Consider reputation impact |

| Rush orders | High | Accept calculated risk | Weigh speed vs. quality risk |

| Internal QC team | Medium | Supplement with external audits | Maintain objectivity |

Important Industry Consensus: Experts strongly advise against completely eliminating inspections, even for trusted suppliers. Even reliable suppliers can experience occasional quality issues due to staff changes, material substitutions, or process modifications. A more prudent approach involves adjusting inspection frequency rather than eliminating inspections entirely.

Companies with reliable suppliers should consider maintaining at least periodic random inspections to ensure continued quality standards and supplier accountability.

How Can Packaging Companies Benefit from Third-Party Inspections?

Packaging manufacturers face unique quality challenges that make third-party inspections particularly valuable. Quality issues in packaging directly affect product protection, brand image, and regulatory compliance across multiple industries.

Packaging companies benefit from third-party inspections through material quality verification, production process monitoring, final product quality assurance, regulatory compliance for food packaging, brand protection, supply chain risk management, and cost control through waste reduction. Inspections ensure packaging protects products effectively while meeting brand standards and safety requirements.

Material Quality Verification ensures raw materials meet strict specifications including certified paper and board selection from FSC-certified mills, proper density and thickness (GSM), and moisture content verification. Third-party inspections verify that inks and coatings comply with safety standards, including testing for heavy-metal content and migration rates.

Production Process Monitoring helps packaging manufacturers implement statistical process control (SPC) techniques using real-time data to track print density, color consistency, and cut precision. This enables immediate intervention when readings drift beyond set tolerances, maintaining consistent quality throughout production runs.

AI-Driven Visual Inspection Systems can detect defects like scratches, misalignments, and off-register printing at rates exceeding manual inspection capabilities. Functional testing including drop tests, compression tests, and shelf-life simulations ensures packaging withstands storage and transit rigors.

Critical packaging quality areas include:

- Print Quality Verification: Accurate color matching, text legibility, and professional graphics appearance

- Structural Integrity: Proper protection capabilities and functionality under shipping stresses

- Dimensional Accuracy: Correct measurements for product fit and automated equipment compatibility

- Material Compliance: Safety standards and regulatory requirements verification

Regulatory Compliance for Food Packaging becomes critical under China’s modernized food packaging regulations. The Food Safety Law requires strict compliance with National Food Safety Standards. Third-party inspections help verify adherence to quality control requirements throughout production and ensure products meet both Chinese and international food-contact material standards.

Brand Protection and Customer Satisfaction through consistent quality ensures every package represents the brand’s promise to customers. Quality issues can undermine reputation and lead to returns and complaints, making professional inspection a valuable brand protection investment.

Supply Chain Risk Management helps packaging companies verify supplier reliability and capability when sourcing materials or outsourcing production elements. This becomes particularly important for complex packaging requiring multiple components or specialized finishes.

At Acreet, we understand that packaging quality directly impacts your brand success and customer satisfaction. Our commitment to excellence means we actively welcome third-party inspections as validation of our rigorous quality standards. We work closely with inspection services to ensure every custom packaging solution meets your exact specifications and exceeds industry standards.

When you partner with Acreet for your packaging needs, we can recommend trusted inspection services or coordinate seamlessly with your preferred providers. Our transparent approach to quality control demonstrates our confidence in our manufacturing processes and unwavering commitment to your business success.

Summary

Third-party inspection services in China provide essential quality assurance for businesses sourcing products internationally. Industry experts overwhelmingly recommend these services, which cost $149-320 per man-day but prevent significantly larger losses from defective products. The investment delivers objective quality verification, risk reduction, and brand protection that far outweighs the costs through prevented recalls, returns, and reputation damage.

Ready to ensure your custom packaging meets the highest quality standards? Contact Acreet today for expert packaging solutions backed by transparent quality control processes and professional inspection coordination. Let us help you create packaging that protects your products and enhances your brand image. Send us your inquiry for a consultation on your packaging design and manufacturing needs.